Product Description

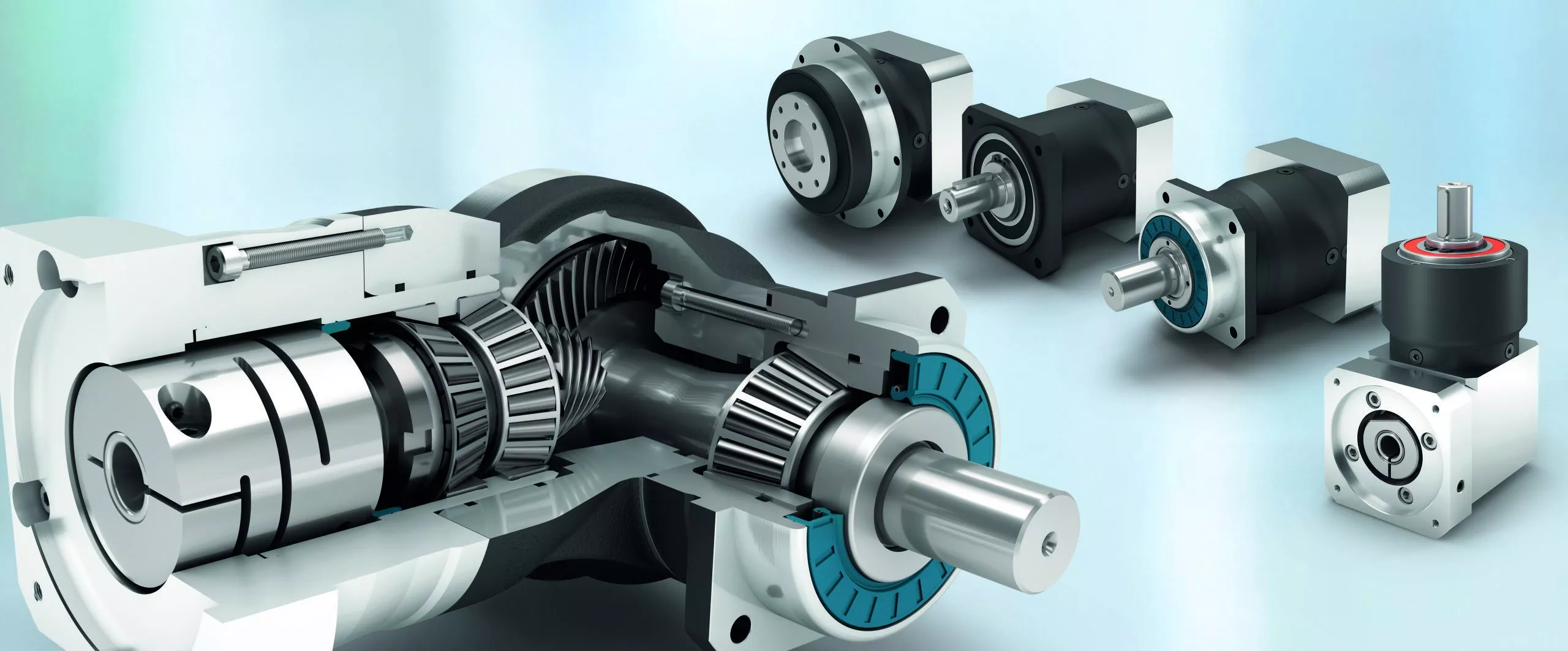

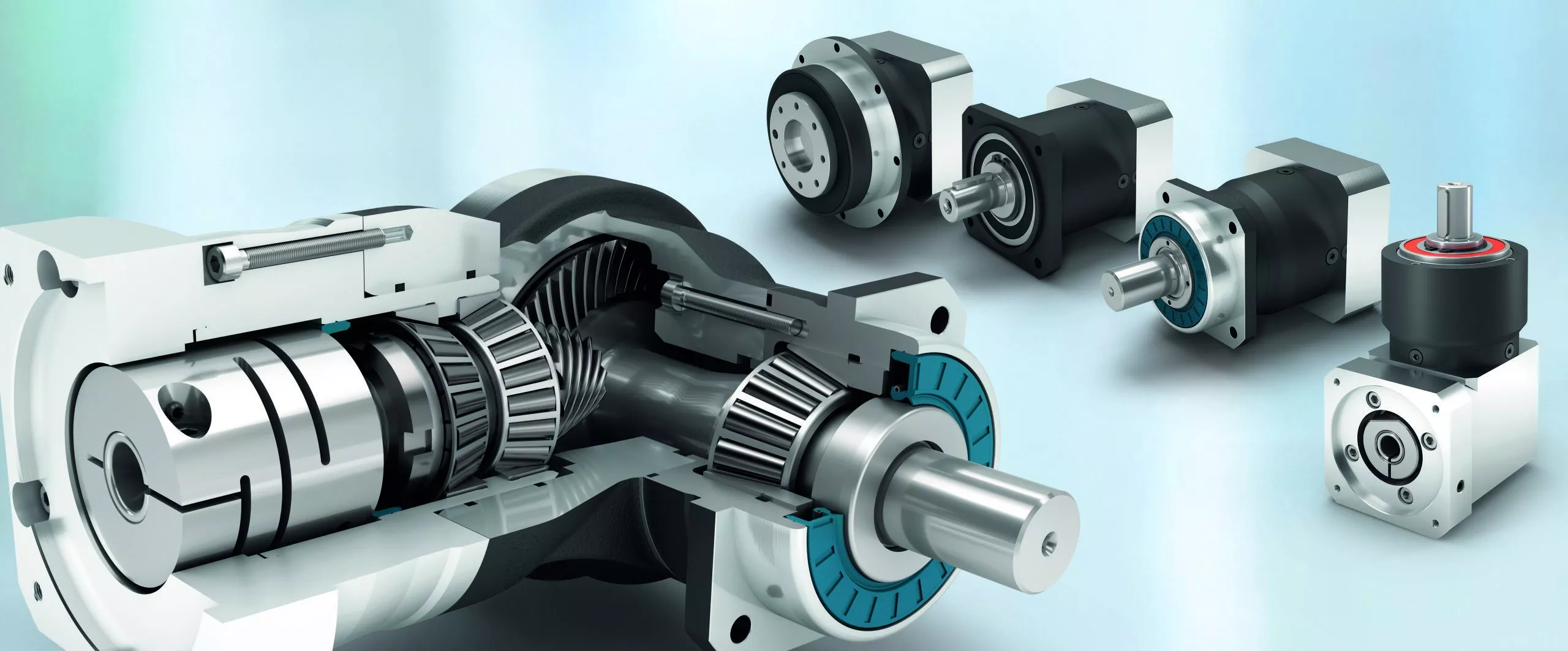

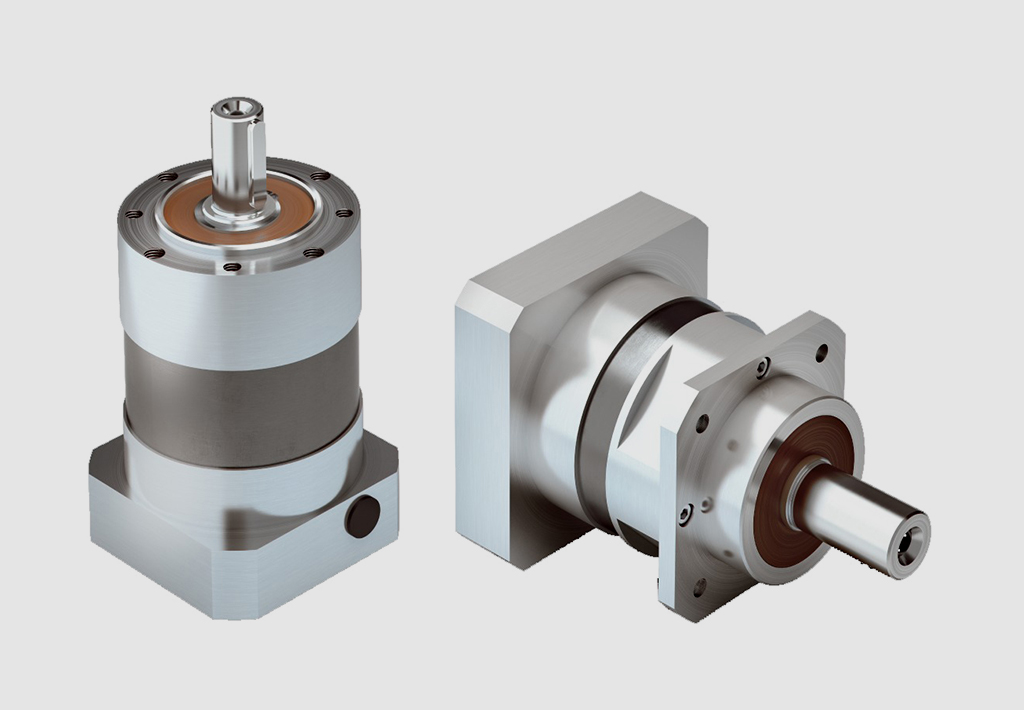

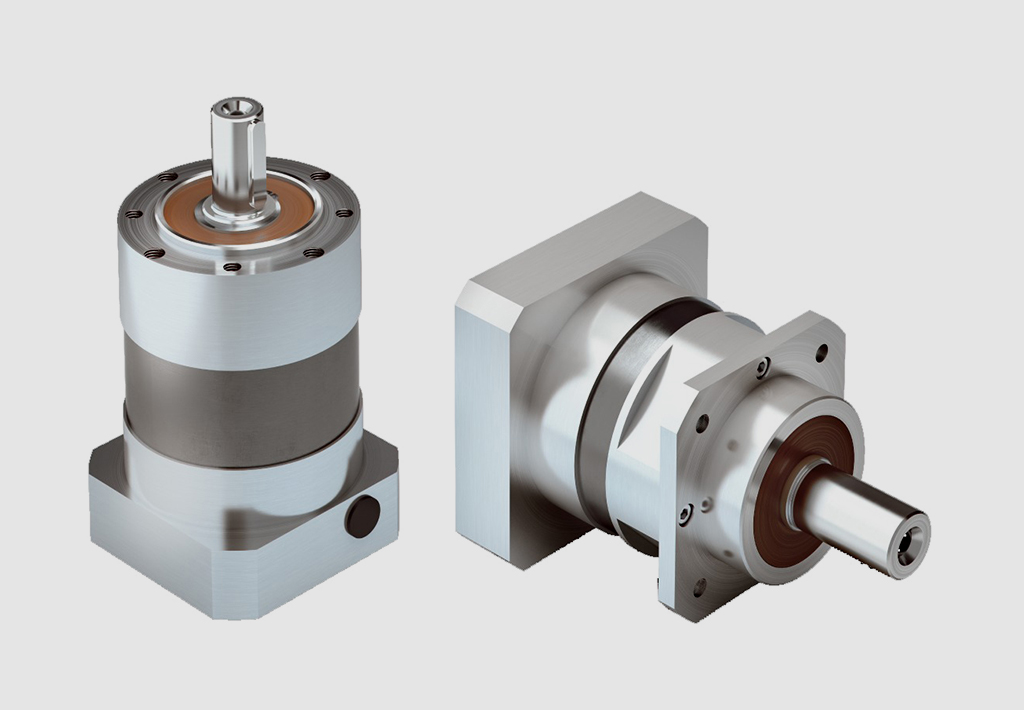

High Precision 1500W Servo Motor Helical Planetary Reducer Gearbox

Planetary gearbox is a kind of reducer with wide versatility. The inner gear adopts low carbon alloy steel carburizing quenching and grinding or nitriding process. Planetary gearbox has the characteristics of small structure size, large output torque, high speed ratio, high efficiency, safe and reliable performance, etc. The inner gear of the planetary gearbox can be divided into spur gear and helical gear. Customers can choose the right precision reducer according to the needs of the application.

Product Description

Description:

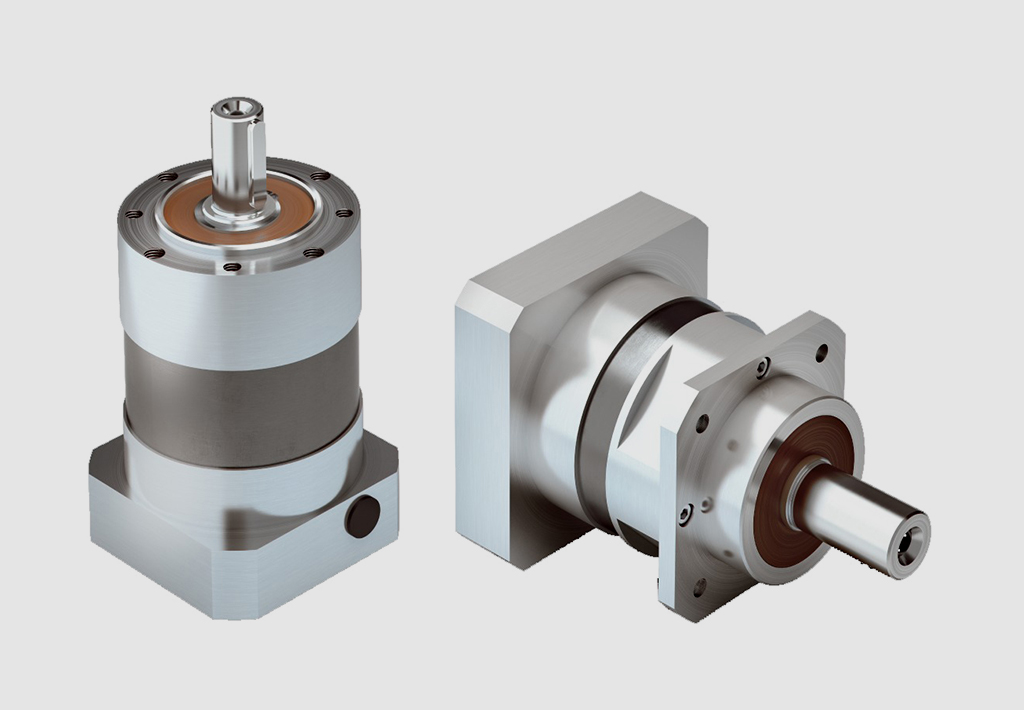

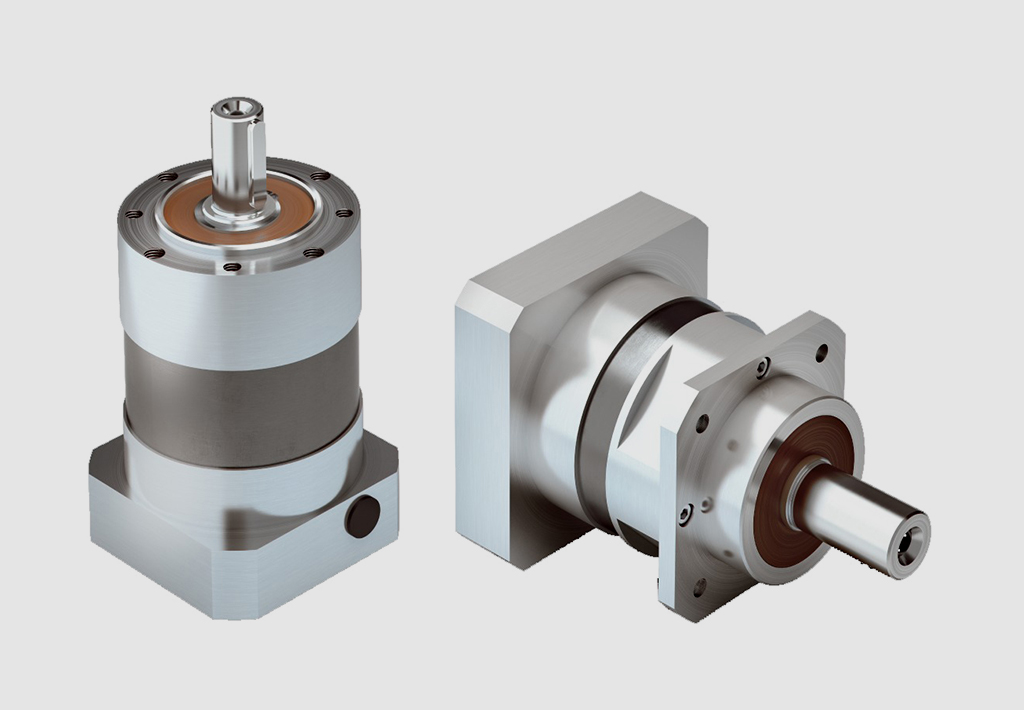

(1).The output shaft is made of large size,large span double bearing design,output shaft and planetary arm bracket as a whole.The input shaft is placed directly on the planet arm bracket to ensure that the reducer has high operating accuracy and maximum torsional rigidity.

(2).Shell and the inner ring gear used integrated design,quenching and tempering after the processing of the teeth so that it can achieve high torque,high precision,high wear resistance.Moreover surface nickel-plated anti-rust treatment,so that its corrosion resistance greatly enhanced.

(3).The planetary gear transmission employs full needle roller without retainer to increase the contact surface,which greatly upgrades structural rigidity and service life.

(4).The gear is made of Japanese imported material.After the metal cutting process,the vacuum carburizing heat treatment to 58-62HRC. And then by the hobbing,Get the best tooth shape,tooth direction,to ensure that the gear of high precision and good impact toughness.

(5).Input shaft and sun gear integrated structure,in order to improve the operation accuracy of the reducer.

Characteristics:

1.Hole output structure,easy installation.

2.Straight tooth drive ,single cantilever structure.simple design,economic price.

3.Working steady. Low noise.

4.Low return backlash. Can suit most occasion.

5.The input connection specifications are complete and there are many choices.

6.Keyway can be opened in the force shaft.

7.Square mount flange output,high precision,high torque.

8.Speed ratio range:3-100

9.Precision range:8-16arcmin

10.Size range:60-160mm

| Specifications | PA60 | PA90 | PA120 | PA140 | PA180 | PA220 | |||

| Technal Parameters | |||||||||

| Max. Torque | Nm | 1.5times rated torque | |||||||

| Emergency Stop Torque | Nm | 2.5times rated torque | |||||||

| Max. Radial Load | N | 1530 | 3250 | 6700 | 9400 | 14500 | 16500 | ||

| Max. Axial Load | N | 630 | 1300 | 3000 | 4700 | 7250 | 8250 | ||

| Torsional Rigidity | Nm/arcmin | 6 | 12 | 23 | 47 | 130 | 205 | ||

| Max.Input Speed | rpm | 8000 | 6000 | 6000 | 6000 | 6000 | 3000 | ||

| Rated Input Speed | rpm | 4000 | 3000 | 3000 | 3000 | 3000 | 1500 | ||

| Noise | dB | ≤58 | ≤60 | ≤65 | ≤68 | ≤68 | ≤72 | ||

| Average Life Time | h | 20000 | |||||||

| Efficiency Of Full Load | % | L1≥95% L2≥90% | |||||||

| Return Backlash | P1 | L1 | arcmin | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| L2 | arcmin | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| P2 | L1 | arcmin | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | |

| L2 | arcmin | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| Moment Of Inertia Table | L1 | 3 | Kg*cm2 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.7 |

| 4 | Kg*cm2 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.61 | ||

| 5 | Kg*cm2 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.51 | ||

| 7 | Kg*cm2 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.92 | ||

| 8 | Kg*cm2 | 0.13 | 0.45 | 2.6 | 7.14 | / | / | ||

| 10 | Kg*cm2 | 0.13 | 0.4 | 2.57 | 7.03 | 22.51 | 50.18 | ||

| L2 | 12 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.63 | 7.3 | 23.59 | |

| 15 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.63 | 7.3 | 23.59 | ||

| 20 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.63 | 6.92 | 23.33 | ||

| 25 | Kg*cm2 | 0.13 | 0.45 | 0.4 | 2.63 | 6.92 | 22.68 | ||

| 28 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.43 | 6.92 | 23.33 | ||

| 30 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.43 | 7.3 | 25.59 | ||

| 35 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.43 | 6.92 | 22.68 | ||

| 40 | Kg*cm2 | 0.13 | 0.45 | 0.45 | 2.43 | 6.92 | 23.33 | ||

| 50 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.39 | 6.92 | 22.68 | ||

| 70 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.39 | 6.72 | 22.68 | ||

| 100 | Kg*cm2 | 0.13 | 0.4 | 0.4 | 2.39 | 6.72 | 22.68 | ||

| Technical Parameter | Level | Ratio | PA60 | PA90 | PA120 | PA140 | PA180 | PA220 | |

| Rated Torque | L1 | 3 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 |

| 4 | Nm | 45 | 130 | 230 | 480 | 880 | 1800 | ||

| 5 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 7 | Nm | 45 | 100 | 220 | 480 | 1100 | 1600 | ||

| 8 | Nm | 40 | 90 | 200 | 440 | / | / | ||

| 10 | Nm | 30 | 75 | 175 | 360 | 770 | 1200 | ||

| L2 | 12 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 | |

| 15 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 | ||

| 20 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 25 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 28 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 30 | Nm | 40 | 105 | 165 | 360 | 880 | 1100 | ||

| 35 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 40 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 50 | Nm | 45 | 130 | 230 | 480 | 1100 | 1800 | ||

| 70 | Nm | 45 | 100 | 220 | 480 | 1100 | 1600 | ||

| 100 | Nm | 30 | 75 | 175 | 360 | 770 | 1200 | ||

| Degree Of Protection | IP65 | ||||||||

| Operation Temprature | ºC | – 10ºC to -90ºC | |||||||

| Weight | L1 | kg | 1.25 | 3.75 | 8.5 | 16 | 28.5 | 49.3 | |

| L2 | kg | 1.75 | 5.1 | 12 | 21.5 | 40 | 62.5 | ||

Company Profile

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Motorcycle, Machinery, Marine, Agricultural Machinery, Manipulator |

|---|---|

| Function: | Change Drive Torque, Change Drive Direction, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Samples: |

US$ 322/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Handling Backlash and Ensuring Precise Positioning in Servo Gearboxes

Servo gearboxes play a critical role in minimizing backlash and ensuring precise positioning in motion control systems:

1. Reduced Backlash Gearing: Many servo gearboxes utilize reduced backlash gearing technology. This involves designing gears with tighter tolerances and improved meshing profiles, resulting in minimal play between gear teeth. This reduces or eliminates backlash, which is essential for accurate motion control.

2. Preloading: Some servo gearboxes employ preloading mechanisms to remove any gaps between gears. By applying a controlled axial load to the gears, the meshing teeth remain in constant contact, eliminating backlash and enhancing precision.

3. Stiffness and Rigidity: Servo gearboxes are designed to be stiff and rigid, which helps minimize elastic deformation under load. This stiffness prevents gear teeth from deflecting, reducing the potential for backlash and maintaining accurate positioning.

4. High Gear Meshing Quality: The manufacturing process of servo gearboxes focuses on producing high-quality gears with precise tooth profiles and minimal manufacturing variations. This ensures consistent and smooth gear meshing, minimizing the likelihood of backlash.

5. Closed-Loop Control: Combining servo gearboxes with closed-loop control systems allows for real-time feedback on position and speed. Any deviation from the desired position can be quickly corrected by adjusting the motor’s output, compensating for any inherent backlash and ensuring precise positioning.

6. Advanced Gear Coatings: Some servo gearboxes incorporate advanced gear coatings or treatments that improve the meshing characteristics and reduce friction. This contributes to smoother gear engagement and minimizes backlash effects.

7. Inertia Matching: Properly matching the inertia of the load to the servo motor and gearbox combination reduces the likelihood of overshooting or oscillations during positioning. Accurate inertia matching enhances the control system’s ability to maintain precise positioning.

Servo gearboxes’ ability to handle backlash and ensure precise positioning is crucial for applications that require high accuracy, such as robotics, CNC machines, and automated manufacturing processes. By employing advanced design techniques and technologies, servo gearboxes contribute to achieving repeatable and accurate motion control.

Contribution of Servo Gearboxes to Energy Efficiency in Automated Systems

Servo gearboxes play a crucial role in enhancing energy efficiency in various automated systems by addressing several key aspects:

1. Precise Control: Servo gearboxes enable precise and accurate control over motion, allowing automated systems to perform tasks with minimal wastage of energy. Precise positioning reduces the need for unnecessary movements and adjustments.

2. Variable Speed Operation: Servo gearboxes offer the flexibility to operate at different speeds based on the application’s requirements. This capability ensures that the system uses only the necessary amount of energy for a given task, avoiding excessive power consumption.

3. Reduced Inertia: Servo gearboxes are designed to minimize inertia, which is the resistance to changes in motion. Lower inertia results in quicker response times and less energy required to accelerate or decelerate moving parts.

4. Regenerative Braking: Some servo systems are equipped with regenerative braking mechanisms. During deceleration or braking, energy generated is fed back into the system or stored for later use, reducing energy wastage.

5. Dynamic Load Management: Servo gearboxes can adapt to varying load conditions in real-time. They adjust torque and speed based on the load, optimizing energy usage and preventing overconsumption of power.

6. Reduced Heat Generation: Efficient servo gearboxes produce less heat during operation, leading to lower energy losses. This reduction in heat generation contributes to overall energy efficiency and extends the lifespan of components.

7. Smart Control Algorithms: Modern servo systems incorporate intelligent control algorithms that optimize the use of energy. These algorithms manage power distribution, minimize idle time, and synchronize movements for optimal efficiency.

8. Energy Recovery: In certain applications, servo gearboxes can capture and reuse energy that would otherwise be dissipated as heat. This energy recovery further contributes to the overall energy efficiency of the system.

9. Low Friction Designs: Servo gearboxes often incorporate low-friction components and efficient lubrication systems to minimize energy losses due to friction.

10. Matched Components: Properly matched servo gearbox and motor combinations ensure that the system operates at its peak efficiency point, minimizing energy consumption.

By incorporating these energy-saving features and capabilities, servo gearboxes enhance the energy efficiency of automated systems, making them more environmentally friendly and cost-effective over the long term.

Benefits of Using a Servo Gearbox for Precise Motion Control

Servo gearboxes offer several advantages when it comes to achieving precise motion control in various applications:

1. Accuracy: Servo gearboxes provide exceptional accuracy in speed and position control, making them suitable for applications that require tight tolerances and precise movements.

2. Low Backlash: These gearboxes are designed to minimize backlash, which is essential for eliminating lost motion and ensuring accurate positioning.

3. High Torque Density: Servo gearboxes offer a high torque-to-size ratio, allowing them to handle significant loads while maintaining a compact footprint.

4. Dynamic Performance: They excel in dynamic performance, enabling rapid changes in speed and direction with minimal overshoot or settling time.

5. Responsiveness: Servo gearboxes respond quickly to control signals, making them ideal for applications that require rapid adjustments and changes in direction.

6. Smooth Operation: These gearboxes provide smooth and precise movement, critical for applications like robotics, where jerky or uneven motion can lead to inaccuracies or damage.

7. Reduces Maintenance: The accuracy and durability of servo gearboxes can reduce wear and tear on other components, leading to lower maintenance requirements.

8. Improved Efficiency: Servo gearboxes offer high efficiency in power transmission, contributing to energy savings and minimizing heat generation.

9. Customization: They can be tailored to specific application needs, including factors like reduction ratios, mounting options, and feedback compatibility.

10. Versatility: Servo gearboxes find application in various industries, including robotics, CNC machining, medical equipment, and automation.

Overall, the benefits of using a servo gearbox for precise motion control make them an essential component in applications that demand accuracy, responsiveness, and reliable performance.

editor by CX 2024-05-03

China manufacturer Input 1480rpm Worm Reducer DC 24V Motor 1000W Smrv40 Worm Gearbox with 24V DC Servo Motor differential gearbox

Product Description

Worm gearbox speed reducer electric motor dc are on sale with high quality for you

SMRV 571-150 worm gear box with flange and electric motor

SMRV+NMRV Double Stage Arrangement Reduction Gear Box

RV Series Worm Gearbox

worm speed reducer

nmrv worm gear motor

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Conical – Cylindrical Gear |

| Step: | Single-Step |

| Samples: |

US$ 69.5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Compatibility of Servo Gearbox with a Specific Motor

The compatibility between a servo gearbox and a specific motor depends on several key factors:

1. Mounting Configuration: The mounting interface of the servo gearbox and motor must be compatible. This includes the type of coupling, flange size, and bolt pattern. Proper alignment ensures efficient power transmission and minimizes mechanical stress.

2. Shaft Diameter and Keyway: The diameter and keyway of the motor shaft must match the input shaft of the servo gearbox. A precise fit prevents slippage and ensures accurate torque transmission.

3. Torque and Speed Ratings: The torque and speed requirements of the application should align with the torque and speed ratings of both the motor and gearbox. Oversizing or undersizing either component can lead to inefficient operation and premature wear.

4. Inertia Matching: Inertia matching between the motor and gearbox helps prevent resonance and oscillations in the system. An appropriate inertia match ensures smooth and precise motion control.

5. Backlash and Stiffness: The gearbox’s backlash (play in the gears) and stiffness characteristics should match the application’s requirements. Low backlash and high stiffness are crucial for accurate positioning tasks.

6. Efficiency and Heat Dissipation: The combined efficiency of the motor and gearbox affects the overall system efficiency. Inadequate efficiency can lead to energy losses and excessive heat generation.

7. Service Life and Maintenance: Compatibility also involves considering the expected service life and maintenance requirements. A well-matched motor-gearbox combination enhances the durability and reliability of the motion control system.

8. Control and Feedback: The control system’s capabilities, such as closed-loop control and feedback devices, play a role in determining compatibility. The motor and gearbox should provide the necessary interfaces for effective integration into the control system.

Manufacturers and engineers often provide guidelines and compatibility charts to assist in selecting the right servo gearbox for a specific motor. Considering these factors ensures optimal performance, efficiency, and longevity of the motion control system.

Contribution of Servo Gearboxes to Smooth Acceleration and Deceleration

Servo gearboxes play a crucial role in ensuring smooth acceleration and deceleration of machinery in motion control systems:

1. Precise Control: Servo gearboxes provide precise control over the rotational speed and torque of the output shaft. This control allows for gradual and controlled changes in speed, resulting in smooth acceleration and deceleration.

2. Feedback Mechanism: Servo systems typically incorporate feedback devices such as encoders or resolvers. These devices continuously monitor the actual position and speed of the output shaft and provide real-time feedback to the controller. This feedback enables the controller to adjust the input signals to the servo gearbox, ensuring accurate and smooth motion transitions.

3. Dynamic Response: Servo gearboxes are designed for high dynamic response, meaning they can quickly adjust their speed and torque based on the controller’s commands. This responsiveness allows for rapid and smooth changes in speed and direction without sudden jerks or jolts.

4. Programmable Profiles: Many servo systems offer the capability to program acceleration and deceleration profiles. Engineers can define specific acceleration and deceleration curves tailored to the application’s requirements. These profiles ensure that the machinery achieves the desired speed changes gradually and smoothly.

5. Reduced Wear and Tear: The controlled and gradual acceleration and deceleration provided by servo gearboxes reduce the wear and tear on mechanical components. Sudden changes in speed can lead to shock loads and vibration, potentially damaging the machinery. Servo gearboxes help mitigate these effects, extending the lifespan of components.

6. Increased Productivity: Smooth acceleration and deceleration reduce the chances of product damage, improve product quality, and enhance the overall efficiency of the process. This is particularly important in applications where precise motion control is critical.

Overall, servo gearboxes contribute to the seamless acceleration and deceleration of machinery by providing accurate control, dynamic responsiveness, and programmable motion profiles. These features ensure that machinery can achieve the desired speed changes while maintaining precision, efficiency, and longevity.

Servo Gearboxes vs. Standard Gearboxes in Industrial Applications

Servo gearboxes and standard gearboxes serve distinct roles in industrial applications. Here’s how they differ:

Precision Control: Servo gearboxes are specifically designed for precise motion control in applications that require accurate speed and position control. Standard gearboxes, while also providing speed reduction or torque multiplication, may not offer the same level of precision.

Backlash: Servo gearboxes are designed to minimize backlash, which is crucial for applications where even slight lost motion is unacceptable. Standard gearboxes may have higher levels of backlash due to their broader design scope.

Dynamic Response: Servo gearboxes excel in dynamic response, enabling quick changes in speed and direction with minimal overshoot. Standard gearboxes may not offer the same level of responsiveness.

High Efficiency: Servo gearboxes are optimized for efficiency to ensure precise power transmission. Standard gearboxes may prioritize other factors like cost or load capacity.

Positioning Accuracy: Servo gearboxes are essential for achieving high positioning accuracy in applications such as robotics and CNC machines. Standard gearboxes might not meet the same accuracy requirements.

Load Distribution: Servo gearboxes distribute loads evenly across gear teeth to enhance durability and minimize wear. Standard gearboxes might not have the same load distribution capabilities.

Compact Design: Servo gearboxes are often designed with a compact form factor to fit within tight spaces. Standard gearboxes might be larger and less optimized for space constraints.

Customization: Servo gearboxes can be highly customizable in terms of size, reduction ratio, and mounting options. Standard gearboxes may offer fewer customization choices.

Application Focus: Servo gearboxes are intended for applications that demand precision and responsiveness, such as robotics, automation, and CNC machining. Standard gearboxes are used in a broader range of applications where precision might not be as critical.

In summary, servo gearboxes are specialized components tailored for high-precision motion control applications, while standard gearboxes serve a wider variety of industrial needs with a focus on durability, load handling, and basic speed reduction.

editor by CX 2024-04-26

China Best Sales Speed Reducer Original CZPT Gearbox for AC Servo Motor Zdh060 supplier

Product Description

Speed Reducer Original CHINAMFG Gearbox For AC Servo Motor ZDH060

-Condition: New And Original

Brand:Delta

Stock: Large

Type: Precison Type And High Precision Rate Type

Stage:1 or 2

-Planetary gearbox is a widely used industrial product, which can reduce the speed of motor and increase the output torque. Planetary reducer can be used as supporting parts in lifting, excavation, transportation, construction and other industries.

-Product picture

-Feature

*High Rigidity, High Torque

Employs uncaged needle roller bearings with a set design including ring teeth, gearbox and helical gears for high rigidity and output torque

*High Precision

Backlash for 1-stage gearbox is under 8 arcmin.

Backlash for 2-stage gearbox is under 12 arcmin.

*High Efficiency

Efficiency for 1-stage model exceeds 95%

Efficiency for 2-stage model exceeds 92%

*Low Noise

Uses helical gears capable of meshing to ensure smooth and quiet operation

*Lifetime Lubrication

The protective class IP65 seal design avoids leakage problems and requires no lubrication during the product’s lifetime.

-Wildly application

*CNC Lathe Machinery, Plasma Cutting Machine , Packing Machinery, Conveyor belt, Wind power gear motor , AC Servo Motor

-We have large stock

-Payment & Package & Delivery

1,Payment

( T/T , Western union, Paypal , L/C and so on )

2,Pakcage

( Small gearbox use carton package, Big gearbox use wooden box package )

3,Delivery

( By International Express, By Air , By Sea )

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Conical – Cylindrical Gear |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Handling Backlash and Ensuring Precise Positioning in Servo Gearboxes

Servo gearboxes play a critical role in minimizing backlash and ensuring precise positioning in motion control systems:

1. Reduced Backlash Gearing: Many servo gearboxes utilize reduced backlash gearing technology. This involves designing gears with tighter tolerances and improved meshing profiles, resulting in minimal play between gear teeth. This reduces or eliminates backlash, which is essential for accurate motion control.

2. Preloading: Some servo gearboxes employ preloading mechanisms to remove any gaps between gears. By applying a controlled axial load to the gears, the meshing teeth remain in constant contact, eliminating backlash and enhancing precision.

3. Stiffness and Rigidity: Servo gearboxes are designed to be stiff and rigid, which helps minimize elastic deformation under load. This stiffness prevents gear teeth from deflecting, reducing the potential for backlash and maintaining accurate positioning.

4. High Gear Meshing Quality: The manufacturing process of servo gearboxes focuses on producing high-quality gears with precise tooth profiles and minimal manufacturing variations. This ensures consistent and smooth gear meshing, minimizing the likelihood of backlash.

5. Closed-Loop Control: Combining servo gearboxes with closed-loop control systems allows for real-time feedback on position and speed. Any deviation from the desired position can be quickly corrected by adjusting the motor’s output, compensating for any inherent backlash and ensuring precise positioning.

6. Advanced Gear Coatings: Some servo gearboxes incorporate advanced gear coatings or treatments that improve the meshing characteristics and reduce friction. This contributes to smoother gear engagement and minimizes backlash effects.

7. Inertia Matching: Properly matching the inertia of the load to the servo motor and gearbox combination reduces the likelihood of overshooting or oscillations during positioning. Accurate inertia matching enhances the control system’s ability to maintain precise positioning.

Servo gearboxes’ ability to handle backlash and ensure precise positioning is crucial for applications that require high accuracy, such as robotics, CNC machines, and automated manufacturing processes. By employing advanced design techniques and technologies, servo gearboxes contribute to achieving repeatable and accurate motion control.

Contribution of Servo Gearboxes to Smooth Acceleration and Deceleration

Servo gearboxes play a crucial role in ensuring smooth acceleration and deceleration of machinery in motion control systems:

1. Precise Control: Servo gearboxes provide precise control over the rotational speed and torque of the output shaft. This control allows for gradual and controlled changes in speed, resulting in smooth acceleration and deceleration.

2. Feedback Mechanism: Servo systems typically incorporate feedback devices such as encoders or resolvers. These devices continuously monitor the actual position and speed of the output shaft and provide real-time feedback to the controller. This feedback enables the controller to adjust the input signals to the servo gearbox, ensuring accurate and smooth motion transitions.

3. Dynamic Response: Servo gearboxes are designed for high dynamic response, meaning they can quickly adjust their speed and torque based on the controller’s commands. This responsiveness allows for rapid and smooth changes in speed and direction without sudden jerks or jolts.

4. Programmable Profiles: Many servo systems offer the capability to program acceleration and deceleration profiles. Engineers can define specific acceleration and deceleration curves tailored to the application’s requirements. These profiles ensure that the machinery achieves the desired speed changes gradually and smoothly.

5. Reduced Wear and Tear: The controlled and gradual acceleration and deceleration provided by servo gearboxes reduce the wear and tear on mechanical components. Sudden changes in speed can lead to shock loads and vibration, potentially damaging the machinery. Servo gearboxes help mitigate these effects, extending the lifespan of components.

6. Increased Productivity: Smooth acceleration and deceleration reduce the chances of product damage, improve product quality, and enhance the overall efficiency of the process. This is particularly important in applications where precise motion control is critical.

Overall, servo gearboxes contribute to the seamless acceleration and deceleration of machinery by providing accurate control, dynamic responsiveness, and programmable motion profiles. These features ensure that machinery can achieve the desired speed changes while maintaining precision, efficiency, and longevity.

Servo Gearboxes vs. Standard Gearboxes in Industrial Applications

Servo gearboxes and standard gearboxes serve distinct roles in industrial applications. Here’s how they differ:

Precision Control: Servo gearboxes are specifically designed for precise motion control in applications that require accurate speed and position control. Standard gearboxes, while also providing speed reduction or torque multiplication, may not offer the same level of precision.

Backlash: Servo gearboxes are designed to minimize backlash, which is crucial for applications where even slight lost motion is unacceptable. Standard gearboxes may have higher levels of backlash due to their broader design scope.

Dynamic Response: Servo gearboxes excel in dynamic response, enabling quick changes in speed and direction with minimal overshoot. Standard gearboxes may not offer the same level of responsiveness.

High Efficiency: Servo gearboxes are optimized for efficiency to ensure precise power transmission. Standard gearboxes may prioritize other factors like cost or load capacity.

Positioning Accuracy: Servo gearboxes are essential for achieving high positioning accuracy in applications such as robotics and CNC machines. Standard gearboxes might not meet the same accuracy requirements.

Load Distribution: Servo gearboxes distribute loads evenly across gear teeth to enhance durability and minimize wear. Standard gearboxes might not have the same load distribution capabilities.

Compact Design: Servo gearboxes are often designed with a compact form factor to fit within tight spaces. Standard gearboxes might be larger and less optimized for space constraints.

Customization: Servo gearboxes can be highly customizable in terms of size, reduction ratio, and mounting options. Standard gearboxes may offer fewer customization choices.

Application Focus: Servo gearboxes are intended for applications that demand precision and responsiveness, such as robotics, automation, and CNC machining. Standard gearboxes are used in a broader range of applications where precision might not be as critical.

In summary, servo gearboxes are specialized components tailored for high-precision motion control applications, while standard gearboxes serve a wider variety of industrial needs with a focus on durability, load handling, and basic speed reduction.

editor by CX 2024-04-15

China best Apex Ab Series Servo Motor Gear Unit Helical Gear Planetary Reducer Gear Reducer Gearbox Price supplier

Product Description

| Product name | Precision Planetary Reducer |

| Model No. | AB42-AB220 |

| Layout form | Planetary structure |

| Speed ratio | 3-512 |

| Output torque | 20-1500N.M |

| Power | 50W~30KW |

| Input speed | 0~4000RPM |

| Output speed | 0~1300RPM |

| Output type | Shaft type |

| Installation | Flange mounting |

Product Description

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% – 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

The Role of Harmonic Drive Servo Gearboxes in Advanced Motion Control Systems

Harmonic Drive servo gearboxes play a crucial role in advanced motion control systems by offering several unique features:

1. High Precision: Harmonic Drive gearboxes are known for their exceptional precision due to the unique gear mechanism they employ. This precision is essential for achieving accurate and repeatable motion control.

2. Zero Backlash: Harmonic Drive gearboxes are designed with zero backlash, which means there is no lost motion between input and output. This feature ensures that the commanded motion is precisely transferred without any delays or inaccuracies.

3. Compact Design: Harmonic Drive gearboxes have a compact structure, making them suitable for applications with limited space. The compact design allows for easy integration into various systems.

4. High Torque Transmission: Despite their compact size, harmonic drive gearboxes can transmit high torque efficiently. This feature is essential for applications that require both high precision and high torque.

5. Smooth Motion: The unique wave generator mechanism in harmonic drive gearboxes contributes to smooth and continuous motion, which is particularly beneficial in applications involving robotic arms, satellite positioning, and more.

6. Reduction Ratios: Harmonic Drive gearboxes offer high reduction ratios in a single-stage, allowing for precise control of output motion even when input motion is at high speeds.

7. Low Maintenance: The absence of backlash and the use of high-quality materials result in reduced wear and maintenance requirements, enhancing the longevity of the gearbox.

8. Advanced Applications: Harmonic Drive gearboxes are commonly used in robotics, aerospace, medical equipment, automation, and other industries where precision and reliability are paramount.

Overall, harmonic drive servo gearboxes are a critical component in achieving advanced motion control, enabling engineers to design and operate complex systems with unparalleled precision and accuracy.

Contribution of Servo Gearboxes to Energy Efficiency in Automated Systems

Servo gearboxes play a crucial role in enhancing energy efficiency in various automated systems by addressing several key aspects:

1. Precise Control: Servo gearboxes enable precise and accurate control over motion, allowing automated systems to perform tasks with minimal wastage of energy. Precise positioning reduces the need for unnecessary movements and adjustments.

2. Variable Speed Operation: Servo gearboxes offer the flexibility to operate at different speeds based on the application’s requirements. This capability ensures that the system uses only the necessary amount of energy for a given task, avoiding excessive power consumption.

3. Reduced Inertia: Servo gearboxes are designed to minimize inertia, which is the resistance to changes in motion. Lower inertia results in quicker response times and less energy required to accelerate or decelerate moving parts.

4. Regenerative Braking: Some servo systems are equipped with regenerative braking mechanisms. During deceleration or braking, energy generated is fed back into the system or stored for later use, reducing energy wastage.

5. Dynamic Load Management: Servo gearboxes can adapt to varying load conditions in real-time. They adjust torque and speed based on the load, optimizing energy usage and preventing overconsumption of power.

6. Reduced Heat Generation: Efficient servo gearboxes produce less heat during operation, leading to lower energy losses. This reduction in heat generation contributes to overall energy efficiency and extends the lifespan of components.

7. Smart Control Algorithms: Modern servo systems incorporate intelligent control algorithms that optimize the use of energy. These algorithms manage power distribution, minimize idle time, and synchronize movements for optimal efficiency.

8. Energy Recovery: In certain applications, servo gearboxes can capture and reuse energy that would otherwise be dissipated as heat. This energy recovery further contributes to the overall energy efficiency of the system.

9. Low Friction Designs: Servo gearboxes often incorporate low-friction components and efficient lubrication systems to minimize energy losses due to friction.

10. Matched Components: Properly matched servo gearbox and motor combinations ensure that the system operates at its peak efficiency point, minimizing energy consumption.

By incorporating these energy-saving features and capabilities, servo gearboxes enhance the energy efficiency of automated systems, making them more environmentally friendly and cost-effective over the long term.

Industries Utilizing Servo Gearboxes

Servo gearboxes find applications in various industries where precise motion control is essential:

1. Robotics and Automation: Servo gearboxes are widely used in robotics and automation systems for accurate and dynamic movement control, enhancing the performance of industrial robots, collaborative robots (cobots), and other automated machinery.

2. Aerospace and Aviation: The aerospace industry utilizes servo gearboxes in aircraft control systems, including ailerons, elevators, and rudders, to ensure precise and responsive flight control.

3. Medical Equipment: Medical devices and equipment, such as surgical robots, diagnostic instruments, and imaging systems, rely on servo gearboxes to achieve precise and controlled movements for medical procedures and patient care.

4. Manufacturing and Assembly: Servo gearboxes are essential in manufacturing and assembly lines for tasks such as pick-and-place operations, conveyor systems, packaging machinery, and precision machining.

5. Automotive Industry: Automotive manufacturing and testing processes benefit from servo gearboxes for tasks such as vehicle assembly, quality control, and testing systems.

6. Semiconductor Manufacturing: High-precision processes in semiconductor manufacturing, including wafer handling and positioning, utilize servo gearboxes to maintain accuracy in microchip fabrication.

7. Material Handling: Servo gearboxes play a role in material handling systems, such as automated guided vehicles (AGVs), palletizers, and cranes, ensuring smooth and controlled movement of goods.

8. Entertainment and Theme Parks: Roller coasters, animatronics, and other entertainment attractions utilize servo gearboxes to create dynamic and engaging experiences for visitors.

9. Textile Industry: Servo gearboxes are used in textile machinery for processes like spinning, weaving, and knitting, enabling precise control of thread tension and fabric movement.

10. Research and Development: In research settings, servo gearboxes are employed for experimentation, testing, and prototyping of mechanical systems and prototypes.

Servo gearboxes provide the necessary precision, flexibility, and reliability required in these industries, enabling advanced motion control and enhancing the efficiency and performance of various applications.

editor by CX 2024-04-12

China Hot selling ZD UL, CE, ISO9001, CCC, RoHS Approved Zero Backlash Robot Joint Reducer Gearbox For Servo Motor Punching Machine, AGV Driver gearbox definition

Product Description

Model Selection

ZD Leader has a wide range of micro motor production lines in the industry, including DC Motor, AC Motor, Brushless Motor, Planetary Gear Motor, Drum Motor, Planetary Gearbox, RV Reducer and Harmonic Gearbox etc. Through technical innovation and customization, we help you create outstanding application systems and provide flexible solutions for various industrial automation situations.

• Model Selection

Our professional sales representive and technical team will choose the right model and transmission solutions for your usage depend on your specific parameters.

• Drawing Request

If you need more product parameters, catalogues, CAD or 3D drawings, please contact us.

• On Your Need

We can modify standard products or customize them to meet your specific needs.

Product Parameters

Model Code:

| E Series | C Series | ||||

| Code | Outline dimension | General model | Code | Outline dimension | The Original code |

| 120 | Φ122 | 6E | 10C | Φ145 | 150 |

| 150 | Φ145 | 20E | 27C | Φ181 | 180 |

| 190 | Φ190 | 40E | 50C | Φ222 | 220 |

| 220 | Φ222 | 80E | 100C | Φ250 | 250 |

| 250 | Φ244 | 110E | 200C | Φ345 | 350 |

| 280 | Φ280 | 160E | 320C | Φ440 | 440 |

| 320 | Φ325 | 320E | 500C | Φ520 | 520 |

| 370 | Φ370 | 450E | |||

Gear Ratio:

| E Series | C Series | ||

| Code | Reduction Ratio | New code | Monomer reduction ratio |

| 120 | 43,53.5,59,79,103 | 10CBX | 27.00 |

| 150 | 81,105,121,141,161 | 27CBX | 36.57 |

| 190 | 81,105,121,153 | 50CBX | 32.54 |

| 220 | 81,101,121,153 | 100CBX | 36.75 |

| 250 | 81,111,161,175.28 | 200CBX | 34.86 |

| 280 | 81,101,129,145,171 | 320CBX | 35.61 |

| 320 | 81,101,118.5,129,141,171,185 | 500CBX | 37.34 |

| 370 | 81,101,118.5,129,154.8,171,192.4 | ||

| Note 1: E series,such as by the shell(pin shell)output,the corresponding reduction ratio by 1 | |||

| Note 2: C series gear ratio refers to the motor installed in the casing of the reduction ratio,if installed on the output flange side,the corresponding reduction ratio by 1 | |||

Type Of RV Reducer

Application Of RV Reeducer

Precision Cycloidal Gearbox is widely used in industrial machinery fields such as machine tool of four-5-axis, pick-up manipulator for die-casting, industrial robot, die-casting feeding machine, manipulator for punching machine, AGV driver, bottle-making machine, UV Printer and etc.

Other Products

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

The Role of Harmonic Drive Servo Gearboxes in Advanced Motion Control Systems

Harmonic Drive servo gearboxes play a crucial role in advanced motion control systems by offering several unique features:

1. High Precision: Harmonic Drive gearboxes are known for their exceptional precision due to the unique gear mechanism they employ. This precision is essential for achieving accurate and repeatable motion control.

2. Zero Backlash: Harmonic Drive gearboxes are designed with zero backlash, which means there is no lost motion between input and output. This feature ensures that the commanded motion is precisely transferred without any delays or inaccuracies.

3. Compact Design: Harmonic Drive gearboxes have a compact structure, making them suitable for applications with limited space. The compact design allows for easy integration into various systems.

4. High Torque Transmission: Despite their compact size, harmonic drive gearboxes can transmit high torque efficiently. This feature is essential for applications that require both high precision and high torque.

5. Smooth Motion: The unique wave generator mechanism in harmonic drive gearboxes contributes to smooth and continuous motion, which is particularly beneficial in applications involving robotic arms, satellite positioning, and more.

6. Reduction Ratios: Harmonic Drive gearboxes offer high reduction ratios in a single-stage, allowing for precise control of output motion even when input motion is at high speeds.

7. Low Maintenance: The absence of backlash and the use of high-quality materials result in reduced wear and maintenance requirements, enhancing the longevity of the gearbox.

8. Advanced Applications: Harmonic Drive gearboxes are commonly used in robotics, aerospace, medical equipment, automation, and other industries where precision and reliability are paramount.

Overall, harmonic drive servo gearboxes are a critical component in achieving advanced motion control, enabling engineers to design and operate complex systems with unparalleled precision and accuracy.

Contribution of Servo Gearboxes to Smooth Acceleration and Deceleration

Servo gearboxes play a crucial role in ensuring smooth acceleration and deceleration of machinery in motion control systems:

1. Precise Control: Servo gearboxes provide precise control over the rotational speed and torque of the output shaft. This control allows for gradual and controlled changes in speed, resulting in smooth acceleration and deceleration.

2. Feedback Mechanism: Servo systems typically incorporate feedback devices such as encoders or resolvers. These devices continuously monitor the actual position and speed of the output shaft and provide real-time feedback to the controller. This feedback enables the controller to adjust the input signals to the servo gearbox, ensuring accurate and smooth motion transitions.

3. Dynamic Response: Servo gearboxes are designed for high dynamic response, meaning they can quickly adjust their speed and torque based on the controller’s commands. This responsiveness allows for rapid and smooth changes in speed and direction without sudden jerks or jolts.

4. Programmable Profiles: Many servo systems offer the capability to program acceleration and deceleration profiles. Engineers can define specific acceleration and deceleration curves tailored to the application’s requirements. These profiles ensure that the machinery achieves the desired speed changes gradually and smoothly.

5. Reduced Wear and Tear: The controlled and gradual acceleration and deceleration provided by servo gearboxes reduce the wear and tear on mechanical components. Sudden changes in speed can lead to shock loads and vibration, potentially damaging the machinery. Servo gearboxes help mitigate these effects, extending the lifespan of components.

6. Increased Productivity: Smooth acceleration and deceleration reduce the chances of product damage, improve product quality, and enhance the overall efficiency of the process. This is particularly important in applications where precise motion control is critical.

Overall, servo gearboxes contribute to the seamless acceleration and deceleration of machinery by providing accurate control, dynamic responsiveness, and programmable motion profiles. These features ensure that machinery can achieve the desired speed changes while maintaining precision, efficiency, and longevity.

Variations in Servo Gearbox Designs

Servo gearboxes come in various designs to meet different torque and speed requirements:

In-Line: In-line servo gearboxes have the input and output shafts aligned in a straight line. These gearboxes are compact and well-suited for applications where space is limited. They can handle a range of torque and speed requirements, making them versatile for various motion control tasks.

Right-Angle: Right-angle servo gearboxes have the input and output shafts oriented at a 90-degree angle. These gearboxes are used when the input and output directions need to change direction, such as in applications with limited space or when the motion needs to be redirected.

Planetary: Planetary servo gearboxes use a planetary gear arrangement to achieve high torque density and compactness. They are suitable for applications requiring high torque transmission with minimal backlash. Planetary gearboxes are commonly used in robotics, CNC machines, and industrial automation.

Harmonic Drive: Harmonic drive servo gearboxes utilize a flexible spline and a wave generator to achieve high gear reduction ratios while maintaining compact size. They offer exceptional accuracy and are often used in applications requiring precise positioning, such as telescope mounts and semiconductor manufacturing equipment.

Helical: Helical servo gearboxes use helical gear teeth to achieve smooth and quiet operation. They are well-suited for applications that require low noise levels and high efficiency. Helical gearboxes are used in various industries, including packaging, printing, and medical devices.

Custom Designs: Some servo gearboxes are custom-designed to meet specific requirements of unique applications. These designs may involve modifications in gear ratios, housing materials, and sealing to ensure optimal performance in specialized tasks.

The choice of servo gearbox design depends on factors such as the required torque, speed, space constraints, efficiency, and precision. Manufacturers offer a range of options to cater to the diverse needs of motion control systems in different industries.

editor by CX 2024-04-10

China high quality ZD Leader 40-120mm Low Backlash High Precision Planetary Reducer Servo Gearbox gearbox and motor

Product Description

ZD LEADER HIGH PRECISION LARGE TORQUE LONG LIFE LOW

BACHLASH PLANETARY GEARBOX REDUCER FOR SERVO MOTOR

Product View

Specification

| ZDE | Round Mounting Flange |

| ZDWE | Right Angle Input Round Mounting Flange |

| ZDF | Square Mounting Flange |

| ZDWF | Right Angle Input Square Mounting Flange |

| Gear Ratio: | |

| Single Stage | 3, 4, 5, 8, 10 |

| Two Stages | 9, 12, 15, 16, 20, 25, 32, 40, 64 |

| Three Stages | 60, 80, 100, 120, 160, 200, 256, 320, 512 |

| SPECIFICATIONS | STAGE | RATIO | 40 | 60 | 80 | 120 | 160 | |

| RATED OUTPUT TORQUE | N.M | 1 | 3 | 4.5 | 12 | 40 | 80 | 400 |

| 4 | 6 | 16 | 50 | 110 | 450 | |||

| 5 | 6 | 16 | 50 | 110 | 450 | |||

| 8 | 5 | 15 | 45 | 100 | 400 | |||

| 10 | 4 | 12 | 40 | 80 | 305 | |||

| 2 | 9 | – | 40 | 100 | 210 | – | ||

| 12 | 16.5 | 40 | 100 | 210 | 700 | |||

| 15 | 16.5 | 40 | 100 | 210 | 700 | |||

| 16 | 20 | 44 | 120 | 260 | 800 | |||

| 20 | 20 | 44 | 120 | 260 | 800 | |||

| 25 | 18 | 40 | 110 | 230 | 700 | |||

| 32 | 20 | 44 | 120 | 260 | 800 | |||

| 40 | 18 | 40 | 110 | 230 | 700 | |||

| 64 | 7.5 | 18 | 45 | 100 | 400 | |||

| 3 | 60 | 16.5 | 40 | 100 | 210 | – | ||

| 80 | 20 | 44 | 120 | 260 | – | |||

| 100 | 20 | 44 | 120 | 260 | – | |||

| 120 | 16.5 | 40 | 100 | 210 | – | |||

| 160 | 20 | 44 | 120 | 260 | – | |||

| 200 | 18 | 40 | 110 | 230 | – | |||

| 256 | 20 | 44 | 120 | 260 | – | |||

| 320 | 18 | 40 | 110 | 230 | – | |||

| 512 | 7.5 | 18 | 45 | 100 | – | |||

| Scram Torque | N.m | 1,2,3 | 3-512 | 2 times of rated torque | ||||

| Rated speed | rpm | 1,2 | 3-512 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Max speed | rpm | 1,2 | 3-100 | 4500 | 4500 | 4500 | 4500 | 4500 |

| Backlash | arcmin | 1 | <12 | <8 | <8 | <8 | <8 | |

| 2 | <15 | <12 | <12 | <12 | <12 | |||

| 3 | <18 | <15 | <15 | <15 | <15 | |||

| Torsional Rigidity | N.M/arcmin | 1,2,3 | 0.7 | 1.8 | 4.5 | 12 | 38 | |

| Allow radial | N | 1,2,3 | 160 | 450 | 900 | 2100 | 6000 | |

| Allow axial | N | 1,2,3 | 80 | 225 | 450 | 1050 | 3000 | |

| Efficiency η | % | 1 | ≥96% | |||||

| 2 | ≥94% | |||||||

| 3 | ≥90% | |||||||

| life | hr | 1,2,3 | 20000 | |||||

| Weight | kg | 1 | 0.4 | 0.9 | 2.1 | 6 | 18 | |

| 2 | 0.5 | 1.1 | 2.6 | 8 | 22 | |||

| 3 | 0.6 | 1.3 | 3.1 | 9.5 | – | |||

| Temperature | ºC | 1,2 | 3-100 | -25ºC~+90ºC | ||||

| Lubrication | 1,2,3 | SYNTHETIC LUBRICATING GREASE | ||||||

| Protection Grade | 1,2,3 | IP 54 | ||||||

| Assembly | Easy and simple | |||||||

| Noise( L=1M) | dB(A) | 1,2 | ≤55 | ≤58 | ≤60 | ≤65 | ≤70 | |

Related Products

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, DC Brushless

Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications

for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor

size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we

can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A:Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional

wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost

and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But

we are very flexible on the lead time, it will depend on the specific orders.

Company Profile

Our Exhibition

Certification

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Soft Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

High-Speed Applications and Accuracy in Servo Gearboxes

Servo gearboxes can indeed be used in high-speed applications without compromising accuracy, thanks to their design features:

1. Precision Engineering: Servo gearboxes are engineered with high precision, which allows them to maintain accurate motion control even at high speeds.

2. Reduced Backlash: Many servo gearbox designs incorporate mechanisms to minimize backlash, which is the lost motion between input and output. This feature enhances accuracy even in high-speed scenarios.

3. Advanced Bearings: High-quality bearings used in servo gearboxes reduce friction and contribute to maintaining accuracy and efficiency at high speeds.

4. Rigid Construction: The rigid construction of servo gearboxes minimizes flexing or deformation under high-speed loads, ensuring that the intended motion is accurately transmitted.

5. Dynamic Balancing: Some servo gearboxes are dynamically balanced to minimize vibrations that could affect accuracy during high-speed operation.

6. Lubrication: Proper lubrication practices play a vital role. The right lubricant minimizes friction, heat, and wear, ensuring accuracy even at high speeds.

7. Feedback Systems: High-speed applications often use feedback systems, such as encoders, to constantly monitor and adjust the positioning. This further enhances accuracy.

8. Advanced Control Algorithms: The combination of accurate gearboxes and advanced control algorithms ensures precise motion profiles even at high speeds.

Overall, servo gearboxes are designed to excel in accuracy, precision, and efficiency, making them suitable for high-speed applications where maintaining accuracy is crucial.

Precision of Gear Tooth Profiles in Servo Gearboxes

Manufacturers take several measures to ensure the precision of gear tooth profiles in servo gearboxes:

1. Advanced Manufacturing Processes: Manufacturers use advanced machining techniques such as CNC (Computer Numerical Control) machining and grinding to achieve high precision in gear tooth profiles. These processes allow for accurate shaping and finishing of the gear teeth.

2. Quality Materials: High-quality materials with consistent properties are selected for manufacturing gear components. This ensures uniformity in the gear teeth and minimizes variations that could affect precision.

3. Tight Tolerances: Manufacturers set tight tolerances for gear tooth dimensions, including pitch, profile, and helix angle. This helps to maintain precise engagement between gear teeth, reducing backlash and ensuring accurate motion control.

4. Quality Control: Rigorous quality control measures are implemented at various stages of the manufacturing process. This includes inspections, measurements, and tests to verify that gear tooth profiles meet the required specifications.

5. CNC Gear Inspection: Manufacturers use CNC gear inspection machines that can measure and analyze gear tooth profiles with high accuracy. These machines generate detailed reports about tooth geometry, ensuring compliance with design specifications.

6. Computer-Aided Design (CAD) and Simulation: Manufacturers use CAD software to design gear tooth profiles with precision. Simulation tools analyze how different factors, such as material properties and manufacturing processes, affect the final gear tooth shape.

7. Profile Corrections: In some cases, manufacturers apply profile corrections to optimize gear tooth profiles. These corrections compensate for any deviations that may occur during the manufacturing process.

8. Feedback from Application: Manufacturers often collaborate closely with end-users to gather feedback on the performance of gearboxes in real-world applications. This feedback helps refine the manufacturing process and improve the precision of gear tooth profiles.

The combination of advanced manufacturing techniques, strict quality control, and continuous improvement processes ensures that servo gearboxes maintain the precision required for accurate motion control in various applications.

Benefits of Using a Servo Gearbox for Precise Motion Control

Servo gearboxes offer several advantages when it comes to achieving precise motion control in various applications:

1. Accuracy: Servo gearboxes provide exceptional accuracy in speed and position control, making them suitable for applications that require tight tolerances and precise movements.

2. Low Backlash: These gearboxes are designed to minimize backlash, which is essential for eliminating lost motion and ensuring accurate positioning.

3. High Torque Density: Servo gearboxes offer a high torque-to-size ratio, allowing them to handle significant loads while maintaining a compact footprint.

4. Dynamic Performance: They excel in dynamic performance, enabling rapid changes in speed and direction with minimal overshoot or settling time.

5. Responsiveness: Servo gearboxes respond quickly to control signals, making them ideal for applications that require rapid adjustments and changes in direction.

6. Smooth Operation: These gearboxes provide smooth and precise movement, critical for applications like robotics, where jerky or uneven motion can lead to inaccuracies or damage.

7. Reduces Maintenance: The accuracy and durability of servo gearboxes can reduce wear and tear on other components, leading to lower maintenance requirements.

8. Improved Efficiency: Servo gearboxes offer high efficiency in power transmission, contributing to energy savings and minimizing heat generation.

9. Customization: They can be tailored to specific application needs, including factors like reduction ratios, mounting options, and feedback compatibility.

10. Versatility: Servo gearboxes find application in various industries, including robotics, CNC machining, medical equipment, and automation.

Overall, the benefits of using a servo gearbox for precise motion control make them an essential component in applications that demand accuracy, responsiveness, and reliable performance.

editor by CX 2024-03-28

China Custom ZD Large Output Torque Spur Helical Gear Planetary Reducer Gearbox For Servo Motor Steeping gearbox design

Product Description

Model Selection

ZD Leader has a wide range of micro motor production lines in the industry, including DC Motor, AC Motor, Brushless Motor, Planetary Gear Motor, Drum Motor, Planetary Gearbox, RV Reducer and Harmonic Gearbox etc. Through technical innovation and customization, we help you create outstanding application systems and provide flexible solutions for various industrial automation situations.

• Model Selection

Our professional sales representive and technical team will choose the right model and transmission solutions for your usage depend on your specific parameters.

• Drawing Request

If you need more product parameters, catalogues, CAD or 3D drawings, please contact us.

• On Your Need

We can modify standard products or customize them to meet your specific needs.

Product Parameters

Type Of RV Reducer

Application Of RV Reeducer

Precision Cycloidal Gearbox is widely used in industrial machinery fields such as machine tool, robot arm, industrial robot, die-casting feeding machine, manipulator for punching machine, AGV driver, bottle-making machine, UV Printer and etc.

Other Products

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Conical – Cylindrical Gear |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Handling Backlash and Ensuring Precise Positioning in Servo Gearboxes

Servo gearboxes play a critical role in minimizing backlash and ensuring precise positioning in motion control systems:

1. Reduced Backlash Gearing: Many servo gearboxes utilize reduced backlash gearing technology. This involves designing gears with tighter tolerances and improved meshing profiles, resulting in minimal play between gear teeth. This reduces or eliminates backlash, which is essential for accurate motion control.

2. Preloading: Some servo gearboxes employ preloading mechanisms to remove any gaps between gears. By applying a controlled axial load to the gears, the meshing teeth remain in constant contact, eliminating backlash and enhancing precision.

3. Stiffness and Rigidity: Servo gearboxes are designed to be stiff and rigid, which helps minimize elastic deformation under load. This stiffness prevents gear teeth from deflecting, reducing the potential for backlash and maintaining accurate positioning.

4. High Gear Meshing Quality: The manufacturing process of servo gearboxes focuses on producing high-quality gears with precise tooth profiles and minimal manufacturing variations. This ensures consistent and smooth gear meshing, minimizing the likelihood of backlash.

5. Closed-Loop Control: Combining servo gearboxes with closed-loop control systems allows for real-time feedback on position and speed. Any deviation from the desired position can be quickly corrected by adjusting the motor’s output, compensating for any inherent backlash and ensuring precise positioning.

6. Advanced Gear Coatings: Some servo gearboxes incorporate advanced gear coatings or treatments that improve the meshing characteristics and reduce friction. This contributes to smoother gear engagement and minimizes backlash effects.

7. Inertia Matching: Properly matching the inertia of the load to the servo motor and gearbox combination reduces the likelihood of overshooting or oscillations during positioning. Accurate inertia matching enhances the control system’s ability to maintain precise positioning.

Servo gearboxes’ ability to handle backlash and ensure precise positioning is crucial for applications that require high accuracy, such as robotics, CNC machines, and automated manufacturing processes. By employing advanced design techniques and technologies, servo gearboxes contribute to achieving repeatable and accurate motion control.

Real-World Examples of Products Using Servo Gearboxes

Servo gearboxes find application in various industries and products, contributing to their precision, efficiency, and performance:

- Industrial Robots: Industrial robots utilize servo gearboxes to achieve precise and controlled movements, enabling tasks such as assembly, welding, and material handling.

- CNC Machines: Computer Numerical Control (CNC) machines use servo gearboxes for accurate positioning and control of cutting tools, resulting in high-quality and complex machining operations.

- Automated Packaging Machines: Servo gearboxes play a vital role in packaging machines by ensuring precise filling, sealing, and labeling of products, leading to consistent packaging quality.

- Medical Devices: Advanced medical devices like robotic surgical systems use servo gearboxes to provide surgeons with precise control and dexterity during minimally invasive procedures.

- Textile Machinery: Servo gearboxes are employed in textile machinery to control the movement of yarn, ensuring uniform and high-quality fabric production.

- Automated Material Handling Systems: Servo gearboxes enable automated conveyors, lifts, and sorting systems to handle materials efficiently and accurately in warehouses and distribution centers.

- Printers and Plotters: High-resolution printers and plotters use servo gearboxes to precisely position print heads and ensure accurate image reproduction.

- Food Processing Equipment: Servo gearboxes are integrated into food processing machines for tasks like slicing, portioning, and mixing, ensuring consistent product quality and yield.

- Pharmaceutical Manufacturing: Pharmaceutical machinery relies on servo gearboxes for precise dosage and filling operations, crucial for drug production.

- Aerospace Components: Aerospace systems, such as landing gear mechanisms and control surfaces, use servo gearboxes to achieve precise movement and ensure the safety of flight.

These examples demonstrate the widespread adoption of servo gearboxes across various industries, where precision, accuracy, and controlled motion are critical for efficient and high-performance operations.

Servo Gearboxes vs. Standard Gearboxes in Industrial Applications

Servo gearboxes and standard gearboxes serve distinct roles in industrial applications. Here’s how they differ:

Precision Control: Servo gearboxes are specifically designed for precise motion control in applications that require accurate speed and position control. Standard gearboxes, while also providing speed reduction or torque multiplication, may not offer the same level of precision.

Backlash: Servo gearboxes are designed to minimize backlash, which is crucial for applications where even slight lost motion is unacceptable. Standard gearboxes may have higher levels of backlash due to their broader design scope.

Dynamic Response: Servo gearboxes excel in dynamic response, enabling quick changes in speed and direction with minimal overshoot. Standard gearboxes may not offer the same level of responsiveness.

High Efficiency: Servo gearboxes are optimized for efficiency to ensure precise power transmission. Standard gearboxes may prioritize other factors like cost or load capacity.

Positioning Accuracy: Servo gearboxes are essential for achieving high positioning accuracy in applications such as robotics and CNC machines. Standard gearboxes might not meet the same accuracy requirements.

Load Distribution: Servo gearboxes distribute loads evenly across gear teeth to enhance durability and minimize wear. Standard gearboxes might not have the same load distribution capabilities.

Compact Design: Servo gearboxes are often designed with a compact form factor to fit within tight spaces. Standard gearboxes might be larger and less optimized for space constraints.

Customization: Servo gearboxes can be highly customizable in terms of size, reduction ratio, and mounting options. Standard gearboxes may offer fewer customization choices.

Application Focus: Servo gearboxes are intended for applications that demand precision and responsiveness, such as robotics, automation, and CNC machining. Standard gearboxes are used in a broader range of applications where precision might not be as critical.

In summary, servo gearboxes are specialized components tailored for high-precision motion control applications, while standard gearboxes serve a wider variety of industrial needs with a focus on durability, load handling, and basic speed reduction.

editor by CX 2024-03-26

China Best Sales Hot Sale CZPT Gvb Box Gearbox Servo Motor Gearhead Planetary Gear Reducer supplier

Product Description

TaiBang Motor Industry Group Co., Ltd.

The main products is induction motor, reversible motor, DC brush gear motor, DC brushless gear motor , CH/CV big gear motors , Planetary gear motor ,Worm gear motor etc, which used widely in various fields of manufacturing pipelining, transportation, food, medicine, printing, fabric, packing, office, apparatus, entertainment etc, and is the preferred and matched product for automatic machine.

Model Instruction

GB090-10-P2

| GB | 090 | 571 | P2 |

| Reducer Series Code | External Diameter | Reduction Ratio | Reducer Backlash |

| GB:High Precision Square Flange Output

GBR:High Precision Right Angle Square Flange Output GE:High Precision Round Flange Output GER:High Precision Right Round Flange Output |

050:ø50mm 070:ø70mm 090:ø90mm 120:ø120mm 155:ø155mm 205:ø205mm 235:ø235mm 042:42x42mm 060:60x60mm 090:90x90mm 115:115x115mm 142:142x142mm 180:180x180mm 220:220x220mm |

571 means 1:10 | P0:High Precision Backlash

P1:Precison Backlash P2:Standard Backlash |

Main Technical Performance

| Item | Number of stage | Reduction Ratio | GB042 | GB060 | GB060A | GB090 | GB090A | GB115 | GB142 | GB180 | GB220 |

| Rotary Inertia | 1 | 3 | 0.03 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.61 | ||

| 4 | 0.03 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.37 | ||||

| 5 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | ||||

| 6 | 0.03 | 0.13 | 0.45 | 2.65 | 7.25 | 22.75 | 51.72 | ||||

| 7 | 0.03 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.97 | ||||

| 8 | 0.03 | 0.13 | 0.44 | 2.58 | 7.07 | 22.59 | 50.84 | ||||

| 9 | 0.03 | 0.13 | 0.44 | 2.57 | 7.04 | 22.53 | 50.63 | ||||

| 10 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | 50.56 | ||||

| 2 | 15 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | |

| 20 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | ||

| 25 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | ||

| 30 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | ||

| 35 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | ||

| 40 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | ||

| 45 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | ||

| 50 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 | ||

| 60 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 | ||

| 70 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 | ||

| 80 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 | ||

| 90 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 | ||

| 100 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 |

| Item | Number of stage | GB042 | GB060 | GB060A | GB90 | GB090A | GB115 | GB142 | GB180 | GB220 | |

| Backlash(arcmin) | High Precision P0 | 1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |||

| 2 | ≤3 | ≤3 | ≤3 | ≤3 | |||||||

| Precision P1 | 1 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| 2 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| Standard P2 | 1 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | |

| 2 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| Torsional Rigidity(N.M/arcmin) | 1 | 3 | 7 | 7 | 14 | 14 | 25 | 50 | 145 | 225 | |

| 2 | 3 | 7 | 7 | 14 | 14 | 25 | 50 | 145 | 225 | ||

| Noise(dB) | 1,2 | ≤56 | ≤58 | ≤58 | ≤60 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 | |

| Rated input speed(rpm) | 1,2 | 5000 | 5000 | 5000 | 4000 | 4000 | 4000 | 3000 | 3000 | 2000 | |

| Max input speed(rpm) | 1,2 | 10000 | 10000 | 10000 | 8000 | 8000 | 8000 | 6000 | 6000 | 4000 | |

Noise test standard:Distance 1m,no load.Measured with an input speed 3000rpm

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Reduction |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Double-Step |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Lubrication Practices for Maintaining Servo Gearbox Performance

Proper lubrication is essential for maintaining the performance and longevity of servo gearboxes:

1. High-Quality Lubricants: Selecting the right lubricant is crucial. High-quality lubricants with the appropriate viscosity and additives are chosen based on factors like load, speed, and operating conditions.

2. Lubricant Compatibility: Ensure that the chosen lubricant is compatible with the materials used in the gearbox construction, including seals, bearings, and gears.

3. Regular Lubrication Checks: Regularly inspect the lubricant level and condition. Monitor for signs of contamination, degradation, or overheating.

4. Proper Lubricant Amount: Avoid overfilling or underfilling the gearbox. Follow manufacturer guidelines for the correct lubricant amount to ensure optimal performance.

5. Scheduled Lubrication Intervals: Establish a maintenance schedule for lubricant replacement based on operating hours, usage intensity, and environmental conditions.

6. Lubricant Contamination Prevention: Keep the gearbox environment clean and free from contaminants like dust, dirt, and moisture to prevent lubricant contamination.

7. Lubricant Temperature: Monitor and control the operating temperature of the gearbox to prevent lubricant breakdown and ensure proper viscosity.

8. Re-Greasing: In some cases, re-greasing may be necessary due to lubricant aging or displacement. Follow manufacturer recommendations for re-greasing intervals.

9. Seal Inspection: Check the seals regularly for wear and damage. Damaged seals can lead to lubricant leakage and contamination.

10. Expert Consultation: If unsure about lubricant selection or maintenance procedures, consult with experts or follow manufacturer recommendations.

Proper lubrication practices play a critical role in minimizing friction, reducing wear, and ensuring the efficient operation of servo gearboxes in motion control systems.

Contribution of Servo Gearboxes to Smooth Acceleration and Deceleration

Servo gearboxes play a crucial role in ensuring smooth acceleration and deceleration of machinery in motion control systems:

1. Precise Control: Servo gearboxes provide precise control over the rotational speed and torque of the output shaft. This control allows for gradual and controlled changes in speed, resulting in smooth acceleration and deceleration.

2. Feedback Mechanism: Servo systems typically incorporate feedback devices such as encoders or resolvers. These devices continuously monitor the actual position and speed of the output shaft and provide real-time feedback to the controller. This feedback enables the controller to adjust the input signals to the servo gearbox, ensuring accurate and smooth motion transitions.