Product Description

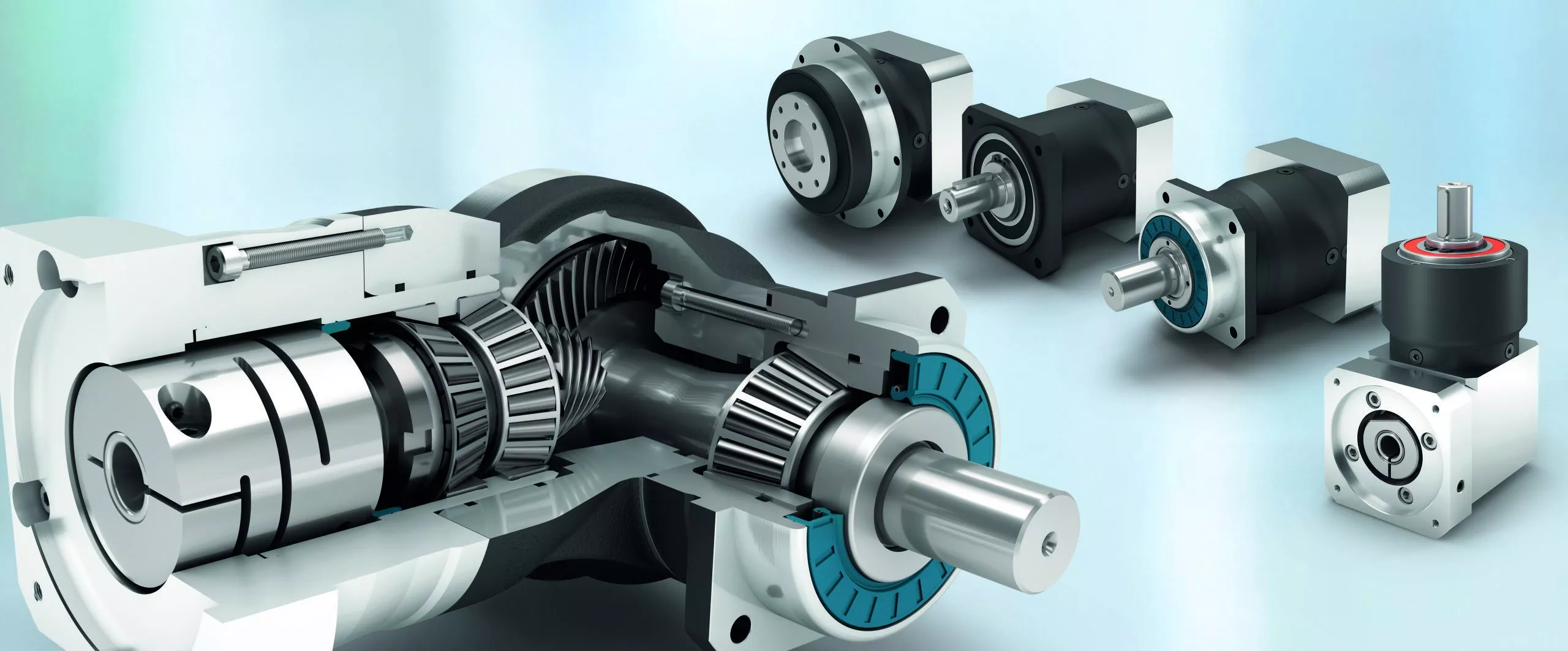

Planetary Gearbox AB Series Square Flange Helical Bevel Planetary Transmission Gearboxes Servo Motor

Product Overview:

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% – 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

Planetary Gearbox AB Series Square Flange Helical Bevel Planetary Transmission Gearboxes Servo Motor

Advantages of the planetary gearbox:

Low backlash

High Efficiency

High Torque

High Input Speed

High Stability

High Reduction Ratio

Detailed Photos

Product Parameters

|

Name |

High Precision Planetary Gearbox |

|

Model |

AB042, AB060, AB060A, AB090A, AB115, AB142, AB180, AB220 |

|

Gearing Arrangement |

Planetary |

|

Effeiency withfull load |

≥97 |

|

Backlash |

≤5 |

|

Weight |

0.5~48kg |

|

Gear Type |

Helical Gear |

|

Gear stages |

1 stage, 2 stage |

|

Rated Torque |

14N.m-2000N.m |

|

Gear Ratio One-stage |

3, 4, 5, 6, 7, 8, 9, 10 |

|

Gear Ratio Two-stage |

15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 |

|

Mounting Position |

Horizontal (foot mounted) or Vertical (flange mounted) |

|

Usage |

stepper motor, servo motor, AC motor, DC motor, etc |

Various reduction ratios available. Please contact us. We will provide you with appropriate reduction gearbox according to your motor power

External Mounting Dimensions

1 stage reduction ratio 3~10

2 stage reduction ratio 15~100

features:

AB-series reducer features:

1. Helical gear design The reduction mechanism adopts the helical gear design, and its tooth shape meshing rate is more than twice that of the general spur gear, and has the characteristics of smooth operation, low noise, high output torque and low backlash

2. Collet type locking mechanism The connection between the input end and the motor adopts a collet-type locking mechanism and undergoes dynamic balance analysis to ensure the concentricity of the joint interface and zero-backlash power transmission at high input speeds

3. Modular design of motor connection board The unique modular design of the motor connecting plate and shaft is suitable for any brand and type of servo motor;

4. Efficient surface treatment technology The surface of the gearbox is treated with electroless nickel, and the connecting plate of the motor is treated with black anodic treatment to improve the environmental tolerance and corrosion resistance

5. One-piece gearbox body The gearbox and the inner ring gear adopt an integrated design, with compact structure, high precision and large output torque

6. Accurate concentricity of gear bar The sun gear made of the whole gear bar has strong rigidity and accurate concentricity

7. Solid, Single piece sun gear construction obtains precise concentricity with increased strength and rigidity. 8.Precision taper roller bearing support to increases radial and axial loading capacity.

Our Advantages

SERIES: AB/ ABR/ AD/ADS/ ADR/ AF/ AFR/ AFX/ AFXR/ AE/ AER/ AE/ AERS

PLF series, PLE series, ZPLF series, ZPLE series, AB series, ABR series and many other models are available.

Applications

Company Profile

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Ab Series Gearbox, Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Lubrication Practices for Maintaining Servo Gearbox Performance

Proper lubrication is essential for maintaining the performance and longevity of servo gearboxes:

1. High-Quality Lubricants: Selecting the right lubricant is crucial. High-quality lubricants with the appropriate viscosity and additives are chosen based on factors like load, speed, and operating conditions.

2. Lubricant Compatibility: Ensure that the chosen lubricant is compatible with the materials used in the gearbox construction, including seals, bearings, and gears.

3. Regular Lubrication Checks: Regularly inspect the lubricant level and condition. Monitor for signs of contamination, degradation, or overheating.

4. Proper Lubricant Amount: Avoid overfilling or underfilling the gearbox. Follow manufacturer guidelines for the correct lubricant amount to ensure optimal performance.

5. Scheduled Lubrication Intervals: Establish a maintenance schedule for lubricant replacement based on operating hours, usage intensity, and environmental conditions.

6. Lubricant Contamination Prevention: Keep the gearbox environment clean and free from contaminants like dust, dirt, and moisture to prevent lubricant contamination.

7. Lubricant Temperature: Monitor and control the operating temperature of the gearbox to prevent lubricant breakdown and ensure proper viscosity.

8. Re-Greasing: In some cases, re-greasing may be necessary due to lubricant aging or displacement. Follow manufacturer recommendations for re-greasing intervals.

9. Seal Inspection: Check the seals regularly for wear and damage. Damaged seals can lead to lubricant leakage and contamination.

10. Expert Consultation: If unsure about lubricant selection or maintenance procedures, consult with experts or follow manufacturer recommendations.

Proper lubrication practices play a critical role in minimizing friction, reducing wear, and ensuring the efficient operation of servo gearboxes in motion control systems.

Contribution of Servo Gearboxes to Energy Efficiency in Automated Systems

Servo gearboxes play a crucial role in enhancing energy efficiency in various automated systems by addressing several key aspects:

1. Precise Control: Servo gearboxes enable precise and accurate control over motion, allowing automated systems to perform tasks with minimal wastage of energy. Precise positioning reduces the need for unnecessary movements and adjustments.

2. Variable Speed Operation: Servo gearboxes offer the flexibility to operate at different speeds based on the application’s requirements. This capability ensures that the system uses only the necessary amount of energy for a given task, avoiding excessive power consumption.

3. Reduced Inertia: Servo gearboxes are designed to minimize inertia, which is the resistance to changes in motion. Lower inertia results in quicker response times and less energy required to accelerate or decelerate moving parts.

4. Regenerative Braking: Some servo systems are equipped with regenerative braking mechanisms. During deceleration or braking, energy generated is fed back into the system or stored for later use, reducing energy wastage.

5. Dynamic Load Management: Servo gearboxes can adapt to varying load conditions in real-time. They adjust torque and speed based on the load, optimizing energy usage and preventing overconsumption of power.

6. Reduced Heat Generation: Efficient servo gearboxes produce less heat during operation, leading to lower energy losses. This reduction in heat generation contributes to overall energy efficiency and extends the lifespan of components.

7. Smart Control Algorithms: Modern servo systems incorporate intelligent control algorithms that optimize the use of energy. These algorithms manage power distribution, minimize idle time, and synchronize movements for optimal efficiency.

8. Energy Recovery: In certain applications, servo gearboxes can capture and reuse energy that would otherwise be dissipated as heat. This energy recovery further contributes to the overall energy efficiency of the system.

9. Low Friction Designs: Servo gearboxes often incorporate low-friction components and efficient lubrication systems to minimize energy losses due to friction.

10. Matched Components: Properly matched servo gearbox and motor combinations ensure that the system operates at its peak efficiency point, minimizing energy consumption.

By incorporating these energy-saving features and capabilities, servo gearboxes enhance the energy efficiency of automated systems, making them more environmentally friendly and cost-effective over the long term.

Industries Utilizing Servo Gearboxes

Servo gearboxes find applications in various industries where precise motion control is essential:

1. Robotics and Automation: Servo gearboxes are widely used in robotics and automation systems for accurate and dynamic movement control, enhancing the performance of industrial robots, collaborative robots (cobots), and other automated machinery.

2. Aerospace and Aviation: The aerospace industry utilizes servo gearboxes in aircraft control systems, including ailerons, elevators, and rudders, to ensure precise and responsive flight control.

3. Medical Equipment: Medical devices and equipment, such as surgical robots, diagnostic instruments, and imaging systems, rely on servo gearboxes to achieve precise and controlled movements for medical procedures and patient care.

4. Manufacturing and Assembly: Servo gearboxes are essential in manufacturing and assembly lines for tasks such as pick-and-place operations, conveyor systems, packaging machinery, and precision machining.

5. Automotive Industry: Automotive manufacturing and testing processes benefit from servo gearboxes for tasks such as vehicle assembly, quality control, and testing systems.

6. Semiconductor Manufacturing: High-precision processes in semiconductor manufacturing, including wafer handling and positioning, utilize servo gearboxes to maintain accuracy in microchip fabrication.

7. Material Handling: Servo gearboxes play a role in material handling systems, such as automated guided vehicles (AGVs), palletizers, and cranes, ensuring smooth and controlled movement of goods.

8. Entertainment and Theme Parks: Roller coasters, animatronics, and other entertainment attractions utilize servo gearboxes to create dynamic and engaging experiences for visitors.

9. Textile Industry: Servo gearboxes are used in textile machinery for processes like spinning, weaving, and knitting, enabling precise control of thread tension and fabric movement.

10. Research and Development: In research settings, servo gearboxes are employed for experimentation, testing, and prototyping of mechanical systems and prototypes.

Servo gearboxes provide the necessary precision, flexibility, and reliability required in these industries, enabling advanced motion control and enhancing the efficiency and performance of various applications.

editor by CX 2024-04-19

China Best Sales Spot High-Precision Helical Planetary Reducer Ab60 42 90 Servo Motor 400W750W 180 Gearbox gearbox design

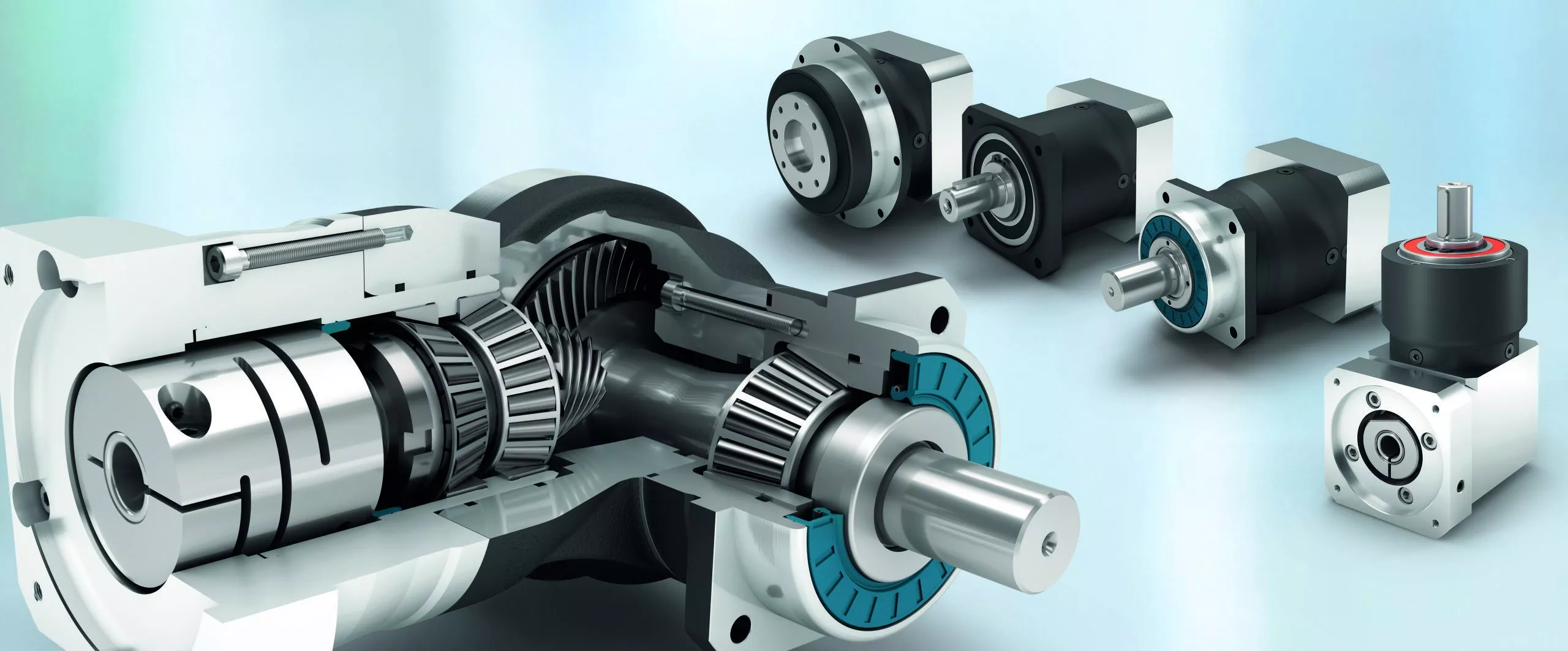

Product Description

Product Description

Detailed Photos

Product Parameters

|

Name |

High Precision Planetary Gearbox |

|

Model |

AB042, AB060, AB060A, AB090A, AB115, AB142, AB180, AB220 |

|

Gearing Arrangement |

Planetary |

|

Effeiency withfull load |

≥97 |

|

Backlash |

≤5 |

|

Weight |

0.5~48kg |

|

Gear Type |

Helical Gear |

|

Gear stages |

1 stage, 2 stage |

|

Rated Torque |

14N.m-2000N.m |

|

Gear Ratio One-stage |

3, 4, 5, 6, 7, 8, 9, 10 |

|

Gear Ratio Two-stage |

15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 |

|

Mounting Position |

Horizontal (foot mounted) or Vertical (flange mounted) |

|

Usage |

stepper motor, servo motor, AC motor, DC motor, etc |

features:

AB-series reducer features:

1. Helical gear design The reduction mechanism adopts the helical gear design, and its tooth shape meshing rate is more than twice that of the general spur gear, and has the characteristics of smooth operation, low noise, high output torque and low backlash

2. Collet type locking mechanism The connection between the input end and the motor adopts a collet-type locking mechanism and undergoes dynamic balance analysis to ensure the concentricity of the joint interface and zero-backlash power transmission at high input speeds

3. Modular design of motor connection board The unique modular design of the motor connecting plate and shaft is suitable for any brand and type of servo motor;

4. Efficient surface treatment technology The surface of the gearbox is treated with electroless nickel, and the connecting plate of the motor is treated with black anodic treatment to improve the environmental tolerance and corrosion resistance

5. One-piece gearbox body The gearbox and the inner ring gear adopt an integrated design, with compact structure, high precision and large output torque

6. Accurate concentricity of gear bar The sun gear made of the whole gear bar has strong rigidity and accurate concentricity

7. Solid, Single piece sun gear construction obtains precise concentricity with increased strength and rigidity. 8.Precision taper roller bearing support to increases radial and axial loading capacity.

Applications

Certifications

Packaging & Shipping

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Ab Series Gearbox, Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Compatibility of Servo Gearbox with a Specific Motor

The compatibility between a servo gearbox and a specific motor depends on several key factors:

1. Mounting Configuration: The mounting interface of the servo gearbox and motor must be compatible. This includes the type of coupling, flange size, and bolt pattern. Proper alignment ensures efficient power transmission and minimizes mechanical stress.

2. Shaft Diameter and Keyway: The diameter and keyway of the motor shaft must match the input shaft of the servo gearbox. A precise fit prevents slippage and ensures accurate torque transmission.

3. Torque and Speed Ratings: The torque and speed requirements of the application should align with the torque and speed ratings of both the motor and gearbox. Oversizing or undersizing either component can lead to inefficient operation and premature wear.

4. Inertia Matching: Inertia matching between the motor and gearbox helps prevent resonance and oscillations in the system. An appropriate inertia match ensures smooth and precise motion control.

5. Backlash and Stiffness: The gearbox’s backlash (play in the gears) and stiffness characteristics should match the application’s requirements. Low backlash and high stiffness are crucial for accurate positioning tasks.

6. Efficiency and Heat Dissipation: The combined efficiency of the motor and gearbox affects the overall system efficiency. Inadequate efficiency can lead to energy losses and excessive heat generation.

7. Service Life and Maintenance: Compatibility also involves considering the expected service life and maintenance requirements. A well-matched motor-gearbox combination enhances the durability and reliability of the motion control system.

8. Control and Feedback: The control system’s capabilities, such as closed-loop control and feedback devices, play a role in determining compatibility. The motor and gearbox should provide the necessary interfaces for effective integration into the control system.

Manufacturers and engineers often provide guidelines and compatibility charts to assist in selecting the right servo gearbox for a specific motor. Considering these factors ensures optimal performance, efficiency, and longevity of the motion control system.

Real-World Examples of Products Using Servo Gearboxes

Servo gearboxes find application in various industries and products, contributing to their precision, efficiency, and performance:

- Industrial Robots: Industrial robots utilize servo gearboxes to achieve precise and controlled movements, enabling tasks such as assembly, welding, and material handling.

- CNC Machines: Computer Numerical Control (CNC) machines use servo gearboxes for accurate positioning and control of cutting tools, resulting in high-quality and complex machining operations.

- Automated Packaging Machines: Servo gearboxes play a vital role in packaging machines by ensuring precise filling, sealing, and labeling of products, leading to consistent packaging quality.

- Medical Devices: Advanced medical devices like robotic surgical systems use servo gearboxes to provide surgeons with precise control and dexterity during minimally invasive procedures.

- Textile Machinery: Servo gearboxes are employed in textile machinery to control the movement of yarn, ensuring uniform and high-quality fabric production.

- Automated Material Handling Systems: Servo gearboxes enable automated conveyors, lifts, and sorting systems to handle materials efficiently and accurately in warehouses and distribution centers.

- Printers and Plotters: High-resolution printers and plotters use servo gearboxes to precisely position print heads and ensure accurate image reproduction.

- Food Processing Equipment: Servo gearboxes are integrated into food processing machines for tasks like slicing, portioning, and mixing, ensuring consistent product quality and yield.

- Pharmaceutical Manufacturing: Pharmaceutical machinery relies on servo gearboxes for precise dosage and filling operations, crucial for drug production.

- Aerospace Components: Aerospace systems, such as landing gear mechanisms and control surfaces, use servo gearboxes to achieve precise movement and ensure the safety of flight.

These examples demonstrate the widespread adoption of servo gearboxes across various industries, where precision, accuracy, and controlled motion are critical for efficient and high-performance operations.

Industries Utilizing Servo Gearboxes

Servo gearboxes find applications in various industries where precise motion control is essential:

1. Robotics and Automation: Servo gearboxes are widely used in robotics and automation systems for accurate and dynamic movement control, enhancing the performance of industrial robots, collaborative robots (cobots), and other automated machinery.

2. Aerospace and Aviation: The aerospace industry utilizes servo gearboxes in aircraft control systems, including ailerons, elevators, and rudders, to ensure precise and responsive flight control.

3. Medical Equipment: Medical devices and equipment, such as surgical robots, diagnostic instruments, and imaging systems, rely on servo gearboxes to achieve precise and controlled movements for medical procedures and patient care.

4. Manufacturing and Assembly: Servo gearboxes are essential in manufacturing and assembly lines for tasks such as pick-and-place operations, conveyor systems, packaging machinery, and precision machining.

5. Automotive Industry: Automotive manufacturing and testing processes benefit from servo gearboxes for tasks such as vehicle assembly, quality control, and testing systems.

6. Semiconductor Manufacturing: High-precision processes in semiconductor manufacturing, including wafer handling and positioning, utilize servo gearboxes to maintain accuracy in microchip fabrication.

7. Material Handling: Servo gearboxes play a role in material handling systems, such as automated guided vehicles (AGVs), palletizers, and cranes, ensuring smooth and controlled movement of goods.

8. Entertainment and Theme Parks: Roller coasters, animatronics, and other entertainment attractions utilize servo gearboxes to create dynamic and engaging experiences for visitors.

9. Textile Industry: Servo gearboxes are used in textile machinery for processes like spinning, weaving, and knitting, enabling precise control of thread tension and fabric movement.

10. Research and Development: In research settings, servo gearboxes are employed for experimentation, testing, and prototyping of mechanical systems and prototypes.

Servo gearboxes provide the necessary precision, flexibility, and reliability required in these industries, enabling advanced motion control and enhancing the efficiency and performance of various applications.

editor by CX 2024-01-25