Product Description

Product Description

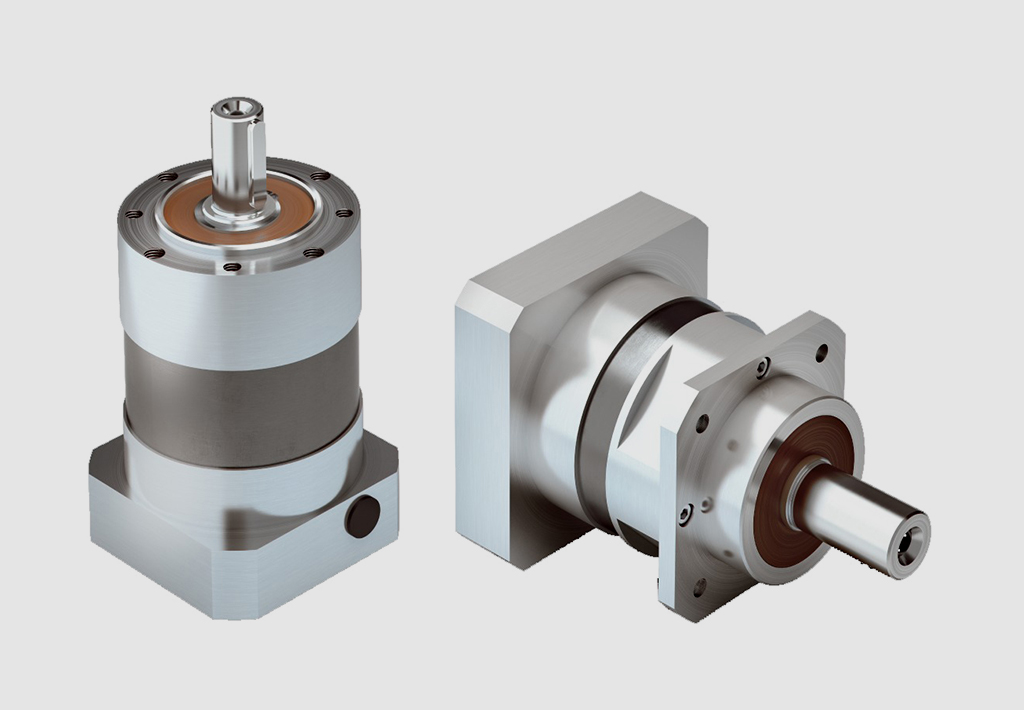

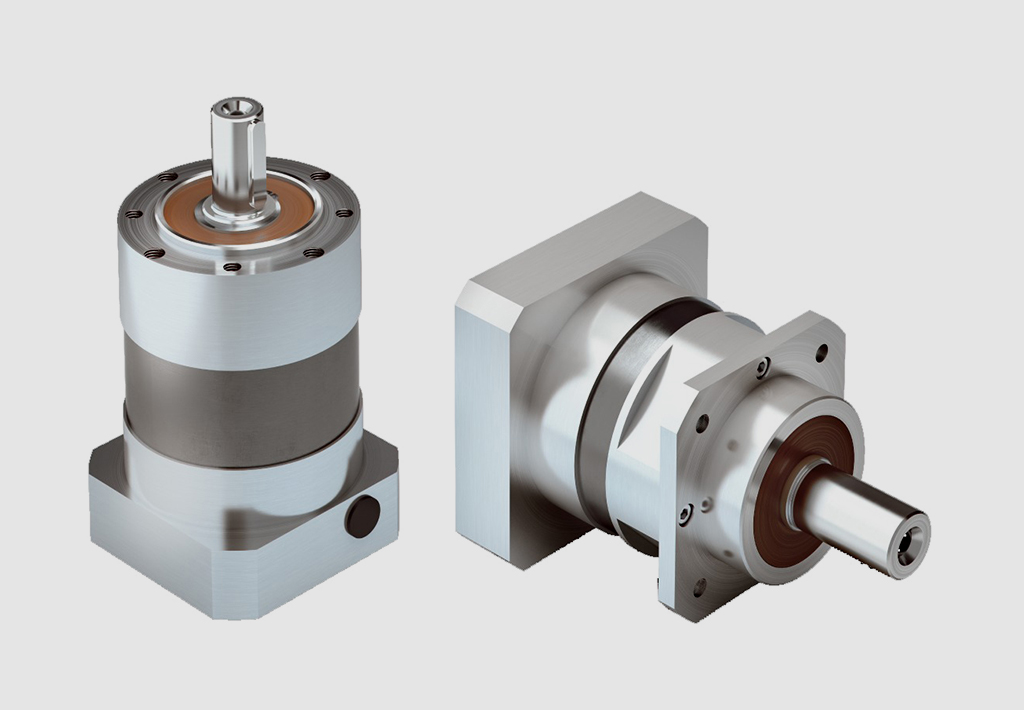

Robotic Joints Reducer

Detailed Photos

Technical data:

Certifications

Company Profile

Xihu (West Lake) Dis.ng Transmission Equipment Co., Ltd. located HangZhou city, ZHangZhoug, as 1 professional manufacturer

and exporter of cycloidal pin wheel reducer,worm reducer, gear reducer, gearbox , AC motor and relative spare

parts, owns rich experience in this line for many years.

We are 1 direct factory, with advanced production equipment, the strong development team and producing

capacity to offer quality products for customers.

Our products widely served to various industries of Metallurgy, Chemicals, lifting,mining,Petroleum,textile,medicine,wooden etc. Main markets: China, Africa,Australia,Vietnam, Turkey,

Japan, Korea, Philippines…

Welcome to ask us any questions, good offer always for you for long term business.

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock.

Q: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.

Q:How to choose a gearbox which meets your requirement?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

Q: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor informationetc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Helical |

| Step: | Single-Step |

The Role of Harmonic Drive Servo Gearboxes in Advanced Motion Control Systems

Harmonic Drive servo gearboxes play a crucial role in advanced motion control systems by offering several unique features:

1. High Precision: Harmonic Drive gearboxes are known for their exceptional precision due to the unique gear mechanism they employ. This precision is essential for achieving accurate and repeatable motion control.

2. Zero Backlash: Harmonic Drive gearboxes are designed with zero backlash, which means there is no lost motion between input and output. This feature ensures that the commanded motion is precisely transferred without any delays or inaccuracies.

3. Compact Design: Harmonic Drive gearboxes have a compact structure, making them suitable for applications with limited space. The compact design allows for easy integration into various systems.

4. High Torque Transmission: Despite their compact size, harmonic drive gearboxes can transmit high torque efficiently. This feature is essential for applications that require both high precision and high torque.

5. Smooth Motion: The unique wave generator mechanism in harmonic drive gearboxes contributes to smooth and continuous motion, which is particularly beneficial in applications involving robotic arms, satellite positioning, and more.

6. Reduction Ratios: Harmonic Drive gearboxes offer high reduction ratios in a single-stage, allowing for precise control of output motion even when input motion is at high speeds.

7. Low Maintenance: The absence of backlash and the use of high-quality materials result in reduced wear and maintenance requirements, enhancing the longevity of the gearbox.

8. Advanced Applications: Harmonic Drive gearboxes are commonly used in robotics, aerospace, medical equipment, automation, and other industries where precision and reliability are paramount.

Overall, harmonic drive servo gearboxes are a critical component in achieving advanced motion control, enabling engineers to design and operate complex systems with unparalleled precision and accuracy.

Disadvantages and Limitations of Using Servo Gear Systems

Servo gear systems offer numerous benefits for precise motion control, but they also come with certain disadvantages and limitations:

1. Cost: Servo gear systems can be more expensive than traditional gearbox solutions. The combination of high-precision components, advanced electronics, and closed-loop control mechanisms can result in higher upfront costs.

2. Complexity: Servo gear systems are complex, requiring expertise in programming, tuning, and integrating the components. Setting up and fine-tuning the system can be time-consuming, especially for applications with intricate motion profiles.

3. Maintenance: The complex nature of servo gear systems can lead to increased maintenance requirements. Regular maintenance, including calibration and monitoring of sensors, is essential to ensure optimal performance and accuracy.

4. Sensitivity to Environmental Factors: Servo systems can be sensitive to environmental conditions such as temperature, humidity, and vibration. Extreme variations in these factors can impact the system’s performance and accuracy.

5. Power Consumption: Servo systems can consume more power compared to other motion control solutions. This is due to the continuous monitoring, feedback processing, and control algorithms that are essential for precise motion control.

6. Size and Weight: In some cases, servo gear systems can be larger and heavier than traditional gearbox setups, which can impact the overall design and space requirements of the machinery or equipment.

7. Overkill for Some Applications: Not all applications require the high precision and capabilities offered by servo gear systems. In simpler applications, the added complexity and cost may not be justified.

8. Compatibility Challenges: Integrating servo gear systems with existing equipment or machinery can be challenging, especially if the components are not designed to work together seamlessly.

While servo gear systems provide exceptional precision and control, it’s important to carefully evaluate the specific requirements of the application and consider the associated disadvantages and limitations before choosing this solution.

Servo Gearboxes vs. Standard Gearboxes in Industrial Applications

Servo gearboxes and standard gearboxes serve distinct roles in industrial applications. Here’s how they differ:

Precision Control: Servo gearboxes are specifically designed for precise motion control in applications that require accurate speed and position control. Standard gearboxes, while also providing speed reduction or torque multiplication, may not offer the same level of precision.

Backlash: Servo gearboxes are designed to minimize backlash, which is crucial for applications where even slight lost motion is unacceptable. Standard gearboxes may have higher levels of backlash due to their broader design scope.

Dynamic Response: Servo gearboxes excel in dynamic response, enabling quick changes in speed and direction with minimal overshoot. Standard gearboxes may not offer the same level of responsiveness.

High Efficiency: Servo gearboxes are optimized for efficiency to ensure precise power transmission. Standard gearboxes may prioritize other factors like cost or load capacity.

Positioning Accuracy: Servo gearboxes are essential for achieving high positioning accuracy in applications such as robotics and CNC machines. Standard gearboxes might not meet the same accuracy requirements.

Load Distribution: Servo gearboxes distribute loads evenly across gear teeth to enhance durability and minimize wear. Standard gearboxes might not have the same load distribution capabilities.

Compact Design: Servo gearboxes are often designed with a compact form factor to fit within tight spaces. Standard gearboxes might be larger and less optimized for space constraints.

Customization: Servo gearboxes can be highly customizable in terms of size, reduction ratio, and mounting options. Standard gearboxes may offer fewer customization choices.

Application Focus: Servo gearboxes are intended for applications that demand precision and responsiveness, such as robotics, automation, and CNC machining. Standard gearboxes are used in a broader range of applications where precision might not be as critical.

In summary, servo gearboxes are specialized components tailored for high-precision motion control applications, while standard gearboxes serve a wider variety of industrial needs with a focus on durability, load handling, and basic speed reduction.

editor by CX 2024-04-02

China Hot selling Short Production Time Harmonic Drive Technologies Hst Harmonic Reducer Gearbox for Servo System sequential gearbox

Product Description

Product Description:

1. Flexspline is a hollow flanging standard cylinder structure.

2. There is a large-diameter hollow shaft hole in the middle of the cam of the wave generator. The internal design of the reducer has a support bearing.

3. It has a fully sealed structure and is easy to install. It is very suitable for occasions where the wire needs to be threaded from the center of the reducer.

Advantages:

1. High precision,high torque

2. Dedicated technical personnel can be on-the-go to provide design solutions

3. Factory direct sales fine workmanship durable quality assurance

4. Product quality issues have a one-year warranty time, can be returned for replacement or repair

Company profile:

HangZhou CHINAMFG Technology Co., Ltd. established in 2014, is committed to the R & D plant of high-precision transmission components. At present, the annual production capacity can reach 45000 sets of harmonic reducers. We firmly believe in quality first. All links from raw materials to finished products are strictly supervised and controlled, which provides a CHINAMFG foundation for product quality. Our products are sold all over the country and abroad.

The harmonic reducer and other high-precision transmission components were independently developed by the company. Our company spends 20% of its sales every year on the research and development of new technologies in the industry. There are 5 people in R & D.

Our advantage is as below:

1.7 years of marketing experience

2. 5-person R & D team to provide you with technical support

3. It is sold at home and abroad and exported to Turkey and Ireland

4. The product quality is guaranteed with a one-year warranty

5. Products can be customized

Strength factory:

Our plant has an entire campus The number of workshops is around 300 Whether it’s from the production of raw materials and the procurement of raw materials to the inspection of finished products, we’re doing it ourselves. There is a complete production system

HST-III Parameter:

| Model | Speed ratio | Enter the rated torque at 2000r/min | Allowed CHINAMFG torque at start stop | The allowable maximum of the average load torque | Maximum torque is allowed in an instant | Allow the maximum speed to be entered | Average input speed is allowed | Back gap | design life | ||||

| NM | kgfm | NM | kgfm | NM | kgfm | NM | kgfm | r / min | r / min | Arc sec | Hour | ||

| 14 | 50 | 6.2 | 0.6 | 20.7 | 2.1 | 7.9 | 0.7 | 40.3 | 4.1 | 7000 | 3000 | ≤30 | 10000 |

| 80 | 9 | 0.9 | 27 | 2.7 | 12.7 | 1.3 | 54.1 | 5.5 | |||||

| 100 | 9 | 0.9 | 32 | 3.3 | 12.7 | 1.3 | 62.1 | 6.3 | |||||

| 17 | 50 | 18.4 | 1.9 | 39 | 4 | 29.9 | 3 | 80.5 | 8.2 | 6500 | 3000 | ≤30 | 15000 |

| 80 | 25.3 | 2.6 | 49.5 | 5 | 31 | 3.2 | 100.1 | 10.2 | |||||

| 100 | 27.6 | 2.8 | 62 | 6.3 | 45 | 4.6 | 124.2 | 12.7 | |||||

| 20 | 50 | 28.8 | 2.9 | 64.4 | 6.6 | 39 | 4 | 112.7 | 11.5 | 5600 | 3000 | ≤30 | 15000 |

| 80 | 39.1 | 4 | 85 | 8.8 | 54 | 5.5 | 146.1 | 14.9 | |||||

| 100 | 46 | 4.7 | 94.3 | 9.6 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 120 | 46 | 4.7 | 100 | 10.2 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 160 | 46 | 4.7 | 100 | 10.2 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 25 | 50 | 44.9 | 4.6 | 113 | 11.5 | 63 | 6.5 | 213.9 | 21.8 | 4800 | 3000 | ≤30 | 15000 |

| 80 | 72.5 | 7.4 | 158 | 16.1 | 100 | 10.2 | 293.3 | 29.9 | |||||

| 100 | 77.1 | 7.9 | 181 | 18.4 | 124 | 12.7 | 326.6 | 33.3 | |||||

| 120 | 77.1 | 7.9 | 192 | 19.6 | 124 | 12.7 | 349.6 | 35.6 | |||||

| 32 | 50 | 87.4 | 8.9 | 248 | 25.3 | 124 | 12.7 | 439 | 44.8 | 4000 | 3000 | ≤30 | 15000 |

| 80 | 135.7 | 13.8 | 350 | 35.6 | 192 | 19.6 | 653 | 66.6 | |||||

| 100 | 157.6 | 16.1 | 383 | 39.1 | 248 | 25.3 | 744 | 75.9 | |||||

| 40 | 100 | 308 | 37.2 | 660 | 67 | 432 | 44 | 1232 | 126.7 | 4000 | 3000 | ≤30 | 15000 |

HSG Parameter:

| Model | Speed ratio | Enter the rated torque at 2000r/min | Allowed CHINAMFG torque at start stop | The allowable maximum of the average load torque | Maximum torque is allowed in an instant | Allow the maximum speed to be entered | Average input speed is allowed | Back gap | design life | ||||

| NM | kgfm | NM | kgfm | NM | kgfm | NM | kgfm | r / min | r / min | Arc sec | Hour | ||

| 14 | 50 | 7 | 0.7 | 23 | 2.3 | 9 | 0.9 | 46 | 4.7 | 14000 | 8500 | ≤20 | 15000 |

| 80 | 10 | 1 | 30 | 3.1 | 14 | 1.4 | 61 | 6.2 | |||||

| 100 | 10 | 1 | 36 | 3.7 | 14 | 1.4 | 70 | 7.2 | |||||

| 17 | 50 | 21 | 2.1 | 44 | 4.5 | 34 | 3.4 | 91 | 9 | 10000 | 7300 | ≤20 | 20000 |

| 80 | 29 | 2.9 | 56 | 5.7 | 35 | 3.6 | 113 | 12 | |||||

| 100 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 143 | 15 | |||||

| 20 | 50 | 33 | 3.3 | 73 | 7.4 | 44 | 4.5 | 127 | 13 | 10000 | 6500 | ≤20 | 20000 |

| 80 | 44 | 4.5 | 96 | 9.8 | 61 | 6.2 | 165 | 17 | |||||

| 100 | 52 | 5.3 | 107 | 10.9 | 64 | 6.5 | 191 | 20 | |||||

| 120 | 52 | 5.3 | 113 | 11.5 | 64 | 6.5 | 191 | 20 | |||||

| 160 | 52 | 5.3 | 120 | 12.2 | 64 | 6.5 | 191 | 20 | |||||

| 25 | 50 | 51 | 5.2 | 127 | 13 | 72 | 7.3 | 242 | 25 | 7500 | 5600 | ≤20 | 20000 |

| 80 | 82 | 8.4 | 178 | 18 | 113 | 12 | 332 | 34 | |||||

| 100 | 87 | 8.9 | 204 | 21 | 140 | 14 | 369 | 38 | |||||

| 120 | 87 | 8.9 | 217 | 22 | 140 | 14 | 395 | 40 | |||||

| 32 | 50 | 99 | 10 | 281 | 29 | 140 | 14 | 497 | 51 | 7000 | 4800 | ≤20 | 20000 |

| 80 | 153 | 16 | 395 | 40 | 217 | 22 | 738 | 75 | |||||

| 100 | 178 | 18 | 433 | 44 | 281 | 29 | 841 | 86 | |||||

| 40 | 100 | 345 | 35 | 738 | 75 | 484 | 49 | 1400 | 143 | 5600 | 4000 | ≤20 | 20000 |

Exhibitions:

Application case:

FQA:

Q: What should I provide when I choose a gearbox/speed reducer?

A: The best way is to provide the motor drawing with parameters. Our engineer will check and recommend the most suitable gearbox model for your reference.

Or you can also provide the below specification as well:

1) Type, model, and torque.

2) Ratio or output speed

3) Working condition and connection method

4) Quality and installed machine name

5) Input mode and input speed

6) Motor brand model or flange and motor shaft size

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery, Hst-I |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

The Role of Harmonic Drive Servo Gearboxes in Advanced Motion Control Systems

Harmonic Drive servo gearboxes play a crucial role in advanced motion control systems by offering several unique features:

1. High Precision: Harmonic Drive gearboxes are known for their exceptional precision due to the unique gear mechanism they employ. This precision is essential for achieving accurate and repeatable motion control.

2. Zero Backlash: Harmonic Drive gearboxes are designed with zero backlash, which means there is no lost motion between input and output. This feature ensures that the commanded motion is precisely transferred without any delays or inaccuracies.

3. Compact Design: Harmonic Drive gearboxes have a compact structure, making them suitable for applications with limited space. The compact design allows for easy integration into various systems.

4. High Torque Transmission: Despite their compact size, harmonic drive gearboxes can transmit high torque efficiently. This feature is essential for applications that require both high precision and high torque.

5. Smooth Motion: The unique wave generator mechanism in harmonic drive gearboxes contributes to smooth and continuous motion, which is particularly beneficial in applications involving robotic arms, satellite positioning, and more.

6. Reduction Ratios: Harmonic Drive gearboxes offer high reduction ratios in a single-stage, allowing for precise control of output motion even when input motion is at high speeds.

7. Low Maintenance: The absence of backlash and the use of high-quality materials result in reduced wear and maintenance requirements, enhancing the longevity of the gearbox.

8. Advanced Applications: Harmonic Drive gearboxes are commonly used in robotics, aerospace, medical equipment, automation, and other industries where precision and reliability are paramount.

Overall, harmonic drive servo gearboxes are a critical component in achieving advanced motion control, enabling engineers to design and operate complex systems with unparalleled precision and accuracy.

Customization of Servo Gearboxes for Specific Industrial Needs

Servo gearboxes can indeed be customized to meet specific industrial requirements. Manufacturers offer customization options to ensure that the servo gearboxes are optimized for the intended applications:

1. Gear Ratio Selection: Depending on the desired speed and torque output, manufacturers can provide various gear ratios to achieve the required motion characteristics.

2. Torque and Speed Ratings: Servo gearboxes can be tailored to handle different torque and speed demands, ensuring that they can efficiently operate within the specified parameters of the application.

3. Mounting Configurations: Manufacturers offer various mounting options, such as flange mounts or shaft mounts, to suit the mechanical layout of the machinery.

4. Output Shaft Configuration: Custom output shaft configurations, such as different diameters or keyway options, can be provided based on the integration requirements.

5. Environmental Considerations: For applications with specific environmental conditions, such as high humidity or extreme temperatures, servo gearboxes can be designed with protective features or special coatings.

6. Lubrication and Sealing: Custom lubrication options and sealing mechanisms can be incorporated to ensure optimal performance and longevity in the given environment.

7. Feedback Devices: Some applications may require specific feedback devices, such as encoders or resolvers, for precise motion control. Manufacturers can integrate these devices into the gearbox design.

8. Noise Reduction: Customized designs can include features that reduce noise and vibration, which is crucial in noise-sensitive applications.

9. Compact Designs: Manufacturers can work on compact designs to accommodate space constraints in the machinery.

10. Integration with Motors: Customized servo gearboxes can be designed to seamlessly integrate with specific types of motors, ensuring efficient power transmission.

By offering customization options, manufacturers enable industries to obtain servo gearboxes that perfectly align with their unique industrial needs, ultimately enhancing performance, precision, and overall system efficiency.

Variations in Servo Gearbox Designs

Servo gearboxes come in various designs to meet different torque and speed requirements:

In-Line: In-line servo gearboxes have the input and output shafts aligned in a straight line. These gearboxes are compact and well-suited for applications where space is limited. They can handle a range of torque and speed requirements, making them versatile for various motion control tasks.

Right-Angle: Right-angle servo gearboxes have the input and output shafts oriented at a 90-degree angle. These gearboxes are used when the input and output directions need to change direction, such as in applications with limited space or when the motion needs to be redirected.

Planetary: Planetary servo gearboxes use a planetary gear arrangement to achieve high torque density and compactness. They are suitable for applications requiring high torque transmission with minimal backlash. Planetary gearboxes are commonly used in robotics, CNC machines, and industrial automation.

Harmonic Drive: Harmonic drive servo gearboxes utilize a flexible spline and a wave generator to achieve high gear reduction ratios while maintaining compact size. They offer exceptional accuracy and are often used in applications requiring precise positioning, such as telescope mounts and semiconductor manufacturing equipment.

Helical: Helical servo gearboxes use helical gear teeth to achieve smooth and quiet operation. They are well-suited for applications that require low noise levels and high efficiency. Helical gearboxes are used in various industries, including packaging, printing, and medical devices.

Custom Designs: Some servo gearboxes are custom-designed to meet specific requirements of unique applications. These designs may involve modifications in gear ratios, housing materials, and sealing to ensure optimal performance in specialized tasks.

The choice of servo gearbox design depends on factors such as the required torque, speed, space constraints, efficiency, and precision. Manufacturers offer a range of options to cater to the diverse needs of motion control systems in different industries.

editor by CX 2024-03-01

China OEM Precision Harmonic Drive Servo Reducer Gearbox gearbox design

Product Description

Product Description:

1.Flexspline is a hollow flanging standard cylinder structure.

2.There is a large-diameter hollow shaft hole in the middle of the cam of the wave generator. The internal design of the reducer has a support bearing.

3.It has a fully sealed structure and is easy to install. It is very suitable for the occasions where the wire needs to be threaded from the center of the reducer.

Advantages:

The first:High precision,high torque

The second:dedicated technical personnel can be on-the-go to provide design solutions

The third:Factory direct sales fine workmanship durable quality assurance

The fourth:Product quality issues have a one-year warranty time, can be returned for replacement or repair

Company profile:

HangZhou CHINAMFG Technology Co., Ltd. established in 2014, is committed to the R & D plant of high-precision transmission components. At present, the annual production capacity can reach 45000 sets of harmonic reducers. We firmly believe in quality first. All links from raw materials to finished products are strictly supervised and controlled, which provides a CHINAMFG foundation for product quality. Our products are sold all over the country and abroad.

The harmonic reducer and other high-precision transmission components were independently developed by the company. Our company spends 20% of its sales every year on the research and development of new technologies in the industry. There are 5 people in R & D.

Our advantage is as below:

1.7 years of marketing experience

2. 5-person R & D team to provide you with technical support

3. It is sold at home and abroad and exported to Turkey and Ireland

4. The product quality is guaranteed with a one-year warranty

5. Products can be customized

Strength factory:

Our plant has an entire campus The number of workshops is around 300 Whether it’s from the production of raw materials and the procurement of raw materials to the inspection of finished products, we’re doing it ourselves. There is a complete production system

HST-III Parameter:

| Model | Speed ratio | Enter the rated torque at 2000r/min | Allowed CHINAMFG torque at start stop | The allowable maximum of the average load torque | Maximum torque is allowed in an instant | Allow the maximum speed to be entered | Average input speed is allowed | Back gap | design life | ||||

| NM | kgfm | NM | kgfm | NM | kgfm | NM | kgfm | r / min | r / min | Arc sec | Hour | ||

| 14 | 50 | 6.2 | 0.6 | 20.7 | 2.1 | 7.9 | 0.7 | 40.3 | 4.1 | 7000 | 3000 | ≤30 | 10000 |

| 80 | 9 | 0.9 | 27 | 2.7 | 12.7 | 1.3 | 54.1 | 5.5 | |||||

| 100 | 9 | 0.9 | 32 | 3.3 | 12.7 | 1.3 | 62.1 | 6.3 | |||||

| 17 | 50 | 18.4 | 1.9 | 39 | 4 | 29.9 | 3 | 80.5 | 8.2 | 6500 | 3000 | ≤30 | 15000 |

| 80 | 25.3 | 2.6 | 49.5 | 5 | 31 | 3.2 | 100.1 | 10.2 | |||||

| 100 | 27.6 | 2.8 | 62 | 6.3 | 45 | 4.6 | 124.2 | 12.7 | |||||

| 20 | 50 | 28.8 | 2.9 | 64.4 | 6.6 | 39 | 4 | 112.7 | 11.5 | 5600 | 3000 | ≤30 | 15000 |

| 80 | 39.1 | 4 | 85 | 8.8 | 54 | 5.5 | 146.1 | 14.9 | |||||

| 100 | 46 | 4.7 | 94.3 | 9.6 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 120 | 46 | 4.7 | 100 | 10.2 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 160 | 46 | 4.7 | 100 | 10.2 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 25 | 50 | 44.9 | 4.6 | 113 | 11.5 | 63 | 6.5 | 213.9 | 21.8 | 4800 | 3000 | ≤30 | 15000 |

| 80 | 72.5 | 7.4 | 158 | 16.1 | 100 | 10.2 | 293.3 | 29.9 | |||||

| 100 | 77.1 | 7.9 | 181 | 18.4 | 124 | 12.7 | 326.6 | 33.3 | |||||

| 120 | 77.1 | 7.9 | 192 | 19.6 | 124 | 12.7 | 349.6 | 35.6 | |||||

| 32 | 50 | 87.4 | 8.9 | 248 | 25.3 | 124 | 12.7 | 439 | 44.8 | 4000 | 3000 | ≤30 | 15000 |

| 80 | 135.7 | 13.8 | 350 | 35.6 | 192 | 19.6 | 653 | 66.6 | |||||

| 100 | 157.6 | 16.1 | 383 | 39.1 | 248 | 25.3 | 744 | 75.9 | |||||

| 40 | 100 | 308 | 37.2 | 660 | 67 | 432 | 44 | 1232 | 126.7 | 4000 | 3000 | ≤30 | 15000 |

HSG Parameter:

| Model | Speed ratio | Enter the rated torque at 2000r/min | Allowed CHINAMFG torque at start stop | The allowable maximum of the average load torque | Maximum torque is allowed in an instant | Allow the maximum speed to be entered | Average input speed is allowed | Back gap | design life | ||||

| NM | kgfm | NM | kgfm | NM | kgfm | NM | kgfm | r / min | r / min | Arc sec | Hour | ||

| 14 | 50 | 7 | 0.7 | 23 | 2.3 | 9 | 0.9 | 46 | 4.7 | 14000 | 8500 | ≤20 | 15000 |

| 80 | 10 | 1 | 30 | 3.1 | 14 | 1.4 | 61 | 6.2 | |||||

| 100 | 10 | 1 | 36 | 3.7 | 14 | 1.4 | 70 | 7.2 | |||||

| 17 | 50 | 21 | 2.1 | 44 | 4.5 | 34 | 3.4 | 91 | 9 | 10000 | 7300 | ≤20 | 20000 |

| 80 | 29 | 2.9 | 56 | 5.7 | 35 | 3.6 | 113 | 12 | |||||

| 100 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 143 | 15 | |||||

| 20 | 50 | 33 | 3.3 | 73 | 7.4 | 44 | 4.5 | 127 | 13 | 10000 | 6500 | ≤20 | 20000 |

| 80 | 44 | 4.5 | 96 | 9.8 | 61 | 6.2 | 165 | 17 | |||||

| 100 | 52 | 5.3 | 107 | 10.9 | 64 | 6.5 | 191 | 20 | |||||

| 120 | 52 | 5.3 | 113 | 11.5 | 64 | 6.5 | 191 | 20 | |||||

| 160 | 52 | 5.3 | 120 | 12.2 | 64 | 6.5 | 191 | 20 | |||||

| 25 | 50 | 51 | 5.2 | 127 | 13 | 72 | 7.3 | 242 | 25 | 7500 | 5600 | ≤20 | 20000 |

| 80 | 82 | 8.4 | 178 | 18 | 113 | 12 | 332 | 34 | |||||

| 100 | 87 | 8.9 | 204 | 21 | 140 | 14 | 369 | 38 | |||||

| 120 | 87 | 8.9 | 217 | 22 | 140 | 14 | 395 | 40 | |||||

| 32 | 50 | 99 | 10 | 281 | 29 | 140 | 14 | 497 | 51 | 7000 | 4800 | ≤20 | 20000 |

| 80 | 153 | 16 | 395 | 40 | 217 | 22 | 738 | 75 | |||||

| 100 | 178 | 18 | 433 | 44 | 281 | 29 | 841 | 86 | |||||

| 40 | 100 | 345 | 35 | 738 | 75 | 484 | 49 | 1400 | 143 | 5600 | 4000 | ≤20 | 20000 |

Exhibition:

Application case:

FQA:

Q: What should I provide when I choose gearbox/speed reducer?

A: The best way is to provide the motor drawing with parameter. Our engineer will check and recommend the most suitable gearbox model for your refer.

Or you can also provide below specification as well:

1) Type, model and torque.

2) Ratio or output speed

3) Working condition and connection method

4) Quality and installed machine name

5) Input mode and input speed

6) Motor brand model or flange and motor shaft size

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

High-Speed Applications and Accuracy in Servo Gearboxes

Servo gearboxes can indeed be used in high-speed applications without compromising accuracy, thanks to their design features:

1. Precision Engineering: Servo gearboxes are engineered with high precision, which allows them to maintain accurate motion control even at high speeds.

2. Reduced Backlash: Many servo gearbox designs incorporate mechanisms to minimize backlash, which is the lost motion between input and output. This feature enhances accuracy even in high-speed scenarios.

3. Advanced Bearings: High-quality bearings used in servo gearboxes reduce friction and contribute to maintaining accuracy and efficiency at high speeds.

4. Rigid Construction: The rigid construction of servo gearboxes minimizes flexing or deformation under high-speed loads, ensuring that the intended motion is accurately transmitted.

5. Dynamic Balancing: Some servo gearboxes are dynamically balanced to minimize vibrations that could affect accuracy during high-speed operation.

6. Lubrication: Proper lubrication practices play a vital role. The right lubricant minimizes friction, heat, and wear, ensuring accuracy even at high speeds.

7. Feedback Systems: High-speed applications often use feedback systems, such as encoders, to constantly monitor and adjust the positioning. This further enhances accuracy.

8. Advanced Control Algorithms: The combination of accurate gearboxes and advanced control algorithms ensures precise motion profiles even at high speeds.

Overall, servo gearboxes are designed to excel in accuracy, precision, and efficiency, making them suitable for high-speed applications where maintaining accuracy is crucial.

Contribution of Servo Gearboxes to Energy Efficiency in Automated Systems

Servo gearboxes play a crucial role in enhancing energy efficiency in various automated systems by addressing several key aspects:

1. Precise Control: Servo gearboxes enable precise and accurate control over motion, allowing automated systems to perform tasks with minimal wastage of energy. Precise positioning reduces the need for unnecessary movements and adjustments.

2. Variable Speed Operation: Servo gearboxes offer the flexibility to operate at different speeds based on the application’s requirements. This capability ensures that the system uses only the necessary amount of energy for a given task, avoiding excessive power consumption.

3. Reduced Inertia: Servo gearboxes are designed to minimize inertia, which is the resistance to changes in motion. Lower inertia results in quicker response times and less energy required to accelerate or decelerate moving parts.

4. Regenerative Braking: Some servo systems are equipped with regenerative braking mechanisms. During deceleration or braking, energy generated is fed back into the system or stored for later use, reducing energy wastage.

5. Dynamic Load Management: Servo gearboxes can adapt to varying load conditions in real-time. They adjust torque and speed based on the load, optimizing energy usage and preventing overconsumption of power.

6. Reduced Heat Generation: Efficient servo gearboxes produce less heat during operation, leading to lower energy losses. This reduction in heat generation contributes to overall energy efficiency and extends the lifespan of components.

7. Smart Control Algorithms: Modern servo systems incorporate intelligent control algorithms that optimize the use of energy. These algorithms manage power distribution, minimize idle time, and synchronize movements for optimal efficiency.

8. Energy Recovery: In certain applications, servo gearboxes can capture and reuse energy that would otherwise be dissipated as heat. This energy recovery further contributes to the overall energy efficiency of the system.

9. Low Friction Designs: Servo gearboxes often incorporate low-friction components and efficient lubrication systems to minimize energy losses due to friction.

10. Matched Components: Properly matched servo gearbox and motor combinations ensure that the system operates at its peak efficiency point, minimizing energy consumption.

By incorporating these energy-saving features and capabilities, servo gearboxes enhance the energy efficiency of automated systems, making them more environmentally friendly and cost-effective over the long term.

Variations in Servo Gearbox Designs

Servo gearboxes come in various designs to meet different torque and speed requirements:

In-Line: In-line servo gearboxes have the input and output shafts aligned in a straight line. These gearboxes are compact and well-suited for applications where space is limited. They can handle a range of torque and speed requirements, making them versatile for various motion control tasks.

Right-Angle: Right-angle servo gearboxes have the input and output shafts oriented at a 90-degree angle. These gearboxes are used when the input and output directions need to change direction, such as in applications with limited space or when the motion needs to be redirected.

Planetary: Planetary servo gearboxes use a planetary gear arrangement to achieve high torque density and compactness. They are suitable for applications requiring high torque transmission with minimal backlash. Planetary gearboxes are commonly used in robotics, CNC machines, and industrial automation.

Harmonic Drive: Harmonic drive servo gearboxes utilize a flexible spline and a wave generator to achieve high gear reduction ratios while maintaining compact size. They offer exceptional accuracy and are often used in applications requiring precise positioning, such as telescope mounts and semiconductor manufacturing equipment.

Helical: Helical servo gearboxes use helical gear teeth to achieve smooth and quiet operation. They are well-suited for applications that require low noise levels and high efficiency. Helical gearboxes are used in various industries, including packaging, printing, and medical devices.

Custom Designs: Some servo gearboxes are custom-designed to meet specific requirements of unique applications. These designs may involve modifications in gear ratios, housing materials, and sealing to ensure optimal performance in specialized tasks.

The choice of servo gearbox design depends on factors such as the required torque, speed, space constraints, efficiency, and precision. Manufacturers offer a range of options to cater to the diverse needs of motion control systems in different industries.

editor by CX 2024-01-26

China Custom Harmonic Drive Gearbox Servo Actuator for Robotic Arm differential gearbox

Product Description

Product Description:

1. Flexspline is a hollow flanging standard cylinder structure.

2. The structure of the whole item is compact. The input shaft is directly matched with the inner hole of the wave generator. They are connected by a flat key slot.

3. The connecting way is circular spline fixed and flexible output, Or it can also be used that flexible fixed and circular spline output.

Advantages:

1. High precision, high torque

2. Dedicated technical personnel can be on-the-go to provide design solutions

3. Factory direct sales fine workmanship durable quality assurance

4. Product quality issues have a one-year warranty time, can be returned for replacement or repair

Company profile:

HangZhou CHINAMFG Technology Co., Ltd. established in 2014, is committed to the R & D plant of high-precision transmission components. At present, the annual production capacity can reach 45000 sets of harmonic reducers. We firmly believe in quality first. All links from raw materials to finished products are strictly supervised and controlled, which provides a CHINAMFG foundation for product quality. Our products are sold all over the country and abroad.

The harmonic reducer and other high-precision transmission components were independently developed by the company. Our company spends 20% of its sales every year on the research and development of new technologies in the industry. There are 5 people in R & D.

Our advantage is as below:

1.7 years of marketing experience

2. 5-person R & D team to provide you with technical support

3. It is sold at home and abroad and exported to Turkey and Ireland

4. The product quality is guaranteed with a one-year warranty

5. Products can be customized

Strength factory:

Our plant has an entire campus The number of workshops is around 300 Whether it’s from the production of raw materials and the procurement of raw materials to the inspection of finished products, we’re doing it ourselves. There is a complete production system

HCS-I Parameter:

| Model | Speed ratio | Enter the rated torque at 2000r/min | Allowed CHINAMFG torque at start stop | The allowable maximum of the average load torque | Maximum torque is allowed in an instant | Allow the maximum speed to be entered | Average input speed is allowed | Back gap | design life | ||||

| NM | kgfm | NM | kgfm | NM | kgfm | NM | kgfm | r / min | r / min | Arc sec | Hour | ||

| 11 | 80 | 3.8 | 0.4 | 8.5 | 0.9 | 6.8 | 0.7 | 19.1 | 1.9 | 8000 | 3000 | ≤30 | 10000 |

| 100 | 4.1 | 0.4 | 8.9 | 0.9 | 7.2 | 0.7 | 20 | 2 | |||||

| 14 | 50 | 6.2 | 0.6 | 20.7 | 2.1 | 7.9 | 0.7 | 40.3 | 4.1 | 7000 | 3000 | ≤30 | 15000 |

| 80 | 9 | 0.9 | 27 | 2.7 | 12.7 | 1.3 | 54.1 | 5.5 | |||||

| 100 | 9 | 0.9 | 32 | 3.3 | 12.7 | 1.3 | 62.1 | 6.3 | |||||

| 17 | 50 | 18.4 | 1.9 | 39 | 4 | 29.9 | 3 | 80.5 | 8.2 | 6500 | 3000 | ≤30 | 15000 |

| 80 | 25.3 | 2.6 | 49.5 | 5 | 31 | 3.2 | 100.1 | 10.2 | |||||

| 100 | 27.6 | 2.8 | 62 | 6.3 | 45 | 4.6 | 124.2 | 12.7 | |||||

| 20 | 50 | 28.8 | 2.9 | 64.4 | 6.6 | 39 | 4 | 112.7 | 11.5 | 5600 | 3000 | ≤30 | 15000 |

| 80 | 39.1 | 4 | 85 | 8.8 | 54 | 5.5 | 146.1 | 14.9 | |||||

| 100 | 46 | 4.7 | 94.3 | 9.6 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 120 | 46 | 4.7 | 100 | 10.2 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 160 | 46 | 4.7 | 112 | 10.9 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 25 | 50 | 44.9 | 4.6 | 113 | 11.5 | 63 | 6.5 | 213.9 | 21.8 | 4800 | 3000 | ≤30 | 15000 |

| 80 | 72.5 | 7.4 | 158 | 16.1 | 100 | 10.2 | 293.3 | 29.9 | |||||

| 100 | 77.1 | 7.9 | 181 | 18.4 | 124 | 12.7 | 326.6 | 33.3 | |||||

| 120 | 77.1 | 7.9 | 192 | 19.6 | 124 | 12.7 | 349.6 | 35.6 | |||||

| 32 | 50 | 87.4 | 8.9 | 248 | 25.3 | 124 | 12.7 | 439 | 44.8 | 4000 | 3000 | ≤30 | 15000 |

| 80 | 135.7 | 13.8 | 350 | 35.6 | 192 | 19.6 | 653 | 66.6 | |||||

| 100 | 157.6 | 16.1 | 383 | 39.1 | 248 | 25.3 | 744 | 75.9 | |||||

| 120 | 157.6 | 16.1 | 406 | 41.4 | 248 | 25.3 | 789 | 80.5 | |||||

HCG Parameter:

| Model | Speed ratio | Enter the rated torque at 2000r/min | Allowed CHINAMFG torque at start stop | The allowable maximum of the average load torque | Maximum torque is allowed in an instant | Allow the maximum speed to be entered | Average input speed is allowed | Back gap | design life | ||||

| NM | kgfm | NM | kgfm | NM | kgfm | NM | kgfm | r / min | r / min | Arc sec | Hour | ||

| 11 | 80 | 3.8 | 0.4 | 8.5 | 0.9 | 6.8 | 0.7 | 19.1 | 1.9 | 8000 | 3000 | ≤20 | 10000 |

| 100 | 4.1 | 0.4 | 8.9 | 0.9 | 7.2 | 0.7 | 20 | 2 | |||||

| 14 | 50 | 7 | 0.7 | 23 | 2.3 | 9 | 0.9 | 46 | 4.7 | 10000 | 6500 | ≤20 | 15000 |

| 80 | 10 | 1 | 30 | 3.1 | 14 | 1.4 | 61 | 6.2 | |||||

| 100 | 10 | 1 | 36 | 3.7 | 14 | 1.4 | 70 | 7.2 | |||||

| 17 | 50 | 21 | 2.1 | 44 | 4.5 | 34 | 3.4 | 91 | 9 | 7500 | 5600 | ≤20 | 20000 |

| 80 | 29 | 2.9 | 56 | 5.7 | 35 | 3.6 | 113 | 12 | |||||

| 100 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 143 | 15 | |||||

| 20 | 50 | 33 | 3.3 | 73 | 7.4 | 44 | 4.5 | 127 | 13 | 7000 | 4800 | ≤20 | 2000 |

| 80 | 44 | 4.5 | 96 | 9.8 | 61 | 6.2 | 165 | 17 | |||||

| 100 | 52 | 5.3 | 107 | 10.9 | 64 | 6.5 | 191 | 20 | |||||

| 120 | 52 | 5.3 | 113 | 11.5 | 64 | 6.5 | 191 | 20 | |||||

| 160 | 52 | 5.3 | 120 | 12.2 | 64 | 6.5 | 191 | 20 | |||||

| 25 | 50 | 51 | 5.2 | 127 | 13 | 72 | 7.3 | 242 | 25 | 5600 | 4000 | ≤20 | 2000 |

| 80 | 82 | 8.4 | 178 | 18 | 113 | 12 | 332 | 34 | |||||

| 100 | 87 | 8.9 | 204 | 21 | 140 | 14 | 369 | 38 | |||||

| 120 | 87 | 8.9 | 217 | 22 | 140 | 14 | 395 | 40 | |||||

| 32 | 50 | 99 | 10 | 281 | 29 | 140 | 14 | 497 | 51 | 5600 | 3000 | ≤20 | 2000 |

| 80 | 153 | 16 | 395 | 40 | 217 | 22 | 738 | 75 | |||||

| 100 | 178 | 18 | 433 | 44 | 281 | 29 | 841 | 86 | |||||

| 120 | 178 | 18 | 459 | 47 | 281 | 29 | 892 | 91 | |||||

Exhibitions:

Application case:

FQA:

Q: What should I provide when I choose a gearbox/speed reducer?

A: The best way is to provide the motor drawing with parameters. Our engineer will check and recommend the most suitable gearbox model for your reference.

Or you can also provide the below specification as well:

1) Type, model, and torque.

2) Ratio or output speed

3) Working condition and connection method

4) Quality and installed machine name

5) Input mode and input speed

6) Motor brand model or flange and motor shaft size

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

High-Speed Applications and Accuracy in Servo Gearboxes

Servo gearboxes can indeed be used in high-speed applications without compromising accuracy, thanks to their design features:

1. Precision Engineering: Servo gearboxes are engineered with high precision, which allows them to maintain accurate motion control even at high speeds.

2. Reduced Backlash: Many servo gearbox designs incorporate mechanisms to minimize backlash, which is the lost motion between input and output. This feature enhances accuracy even in high-speed scenarios.

3. Advanced Bearings: High-quality bearings used in servo gearboxes reduce friction and contribute to maintaining accuracy and efficiency at high speeds.

4. Rigid Construction: The rigid construction of servo gearboxes minimizes flexing or deformation under high-speed loads, ensuring that the intended motion is accurately transmitted.

5. Dynamic Balancing: Some servo gearboxes are dynamically balanced to minimize vibrations that could affect accuracy during high-speed operation.

6. Lubrication: Proper lubrication practices play a vital role. The right lubricant minimizes friction, heat, and wear, ensuring accuracy even at high speeds.

7. Feedback Systems: High-speed applications often use feedback systems, such as encoders, to constantly monitor and adjust the positioning. This further enhances accuracy.

8. Advanced Control Algorithms: The combination of accurate gearboxes and advanced control algorithms ensures precise motion profiles even at high speeds.

Overall, servo gearboxes are designed to excel in accuracy, precision, and efficiency, making them suitable for high-speed applications where maintaining accuracy is crucial.

Contribution of Servo Gearboxes to Smooth Acceleration and Deceleration

Servo gearboxes play a crucial role in ensuring smooth acceleration and deceleration of machinery in motion control systems:

1. Precise Control: Servo gearboxes provide precise control over the rotational speed and torque of the output shaft. This control allows for gradual and controlled changes in speed, resulting in smooth acceleration and deceleration.

2. Feedback Mechanism: Servo systems typically incorporate feedback devices such as encoders or resolvers. These devices continuously monitor the actual position and speed of the output shaft and provide real-time feedback to the controller. This feedback enables the controller to adjust the input signals to the servo gearbox, ensuring accurate and smooth motion transitions.

3. Dynamic Response: Servo gearboxes are designed for high dynamic response, meaning they can quickly adjust their speed and torque based on the controller’s commands. This responsiveness allows for rapid and smooth changes in speed and direction without sudden jerks or jolts.

4. Programmable Profiles: Many servo systems offer the capability to program acceleration and deceleration profiles. Engineers can define specific acceleration and deceleration curves tailored to the application’s requirements. These profiles ensure that the machinery achieves the desired speed changes gradually and smoothly.

5. Reduced Wear and Tear: The controlled and gradual acceleration and deceleration provided by servo gearboxes reduce the wear and tear on mechanical components. Sudden changes in speed can lead to shock loads and vibration, potentially damaging the machinery. Servo gearboxes help mitigate these effects, extending the lifespan of components.

6. Increased Productivity: Smooth acceleration and deceleration reduce the chances of product damage, improve product quality, and enhance the overall efficiency of the process. This is particularly important in applications where precise motion control is critical.

Overall, servo gearboxes contribute to the seamless acceleration and deceleration of machinery by providing accurate control, dynamic responsiveness, and programmable motion profiles. These features ensure that machinery can achieve the desired speed changes while maintaining precision, efficiency, and longevity.

Servo Gearbox: Function in Motion Control Systems

A servo gearbox is a specialized type of gearbox designed to work in conjunction with servo motors to achieve precise motion control in various applications. It functions as follows:

Motion Synchronization: A servo gearbox is used to synchronize the motion of a servo motor with the intended motion of a mechanical system. It ensures that the motor’s rotational output is accurately transmitted to the driven component.

Speed and Position Control: Servo gearboxes enable precise control over speed and position by converting the high-speed, low-torque output of a servo motor into a lower-speed, higher-torque output suitable for the specific application.

Reduction Ratio: The servo gearbox incorporates reduction stages to achieve the desired reduction ratio. This reduction allows the motor to provide higher torque while maintaining accurate speed control.

Backlash Minimization: High-precision servo gearboxes are designed to minimize backlash, which is the lost motion between input and output shafts. This is critical for accurate and responsive motion control.

High Efficiency: Servo gearboxes are designed for high efficiency to ensure that the majority of input power is effectively transferred to the output, reducing energy consumption.

Dynamic Response: Servo gearboxes enhance the dynamic response of motion control systems. They allow the servo motor to quickly start, stop, and change directions with minimal overshooting or oscillations.

Positioning Accuracy: By accurately converting the motor’s rotation into precise linear or angular movement, servo gearboxes ensure high positioning accuracy required in applications such as robotics, CNC machines, and automation systems.

Load Distribution: Servo gearboxes distribute the load evenly across gear teeth, enhancing the gearbox’s durability and minimizing wear.

Customization: Servo gearboxes are available in various sizes, reduction ratios, and configurations to suit different application requirements.

Overall, a servo gearbox is an integral component in motion control systems, allowing precise and efficient control over motion, speed, and position for a wide range of industrial applications.

editor by CX 2023-11-28