Product Description

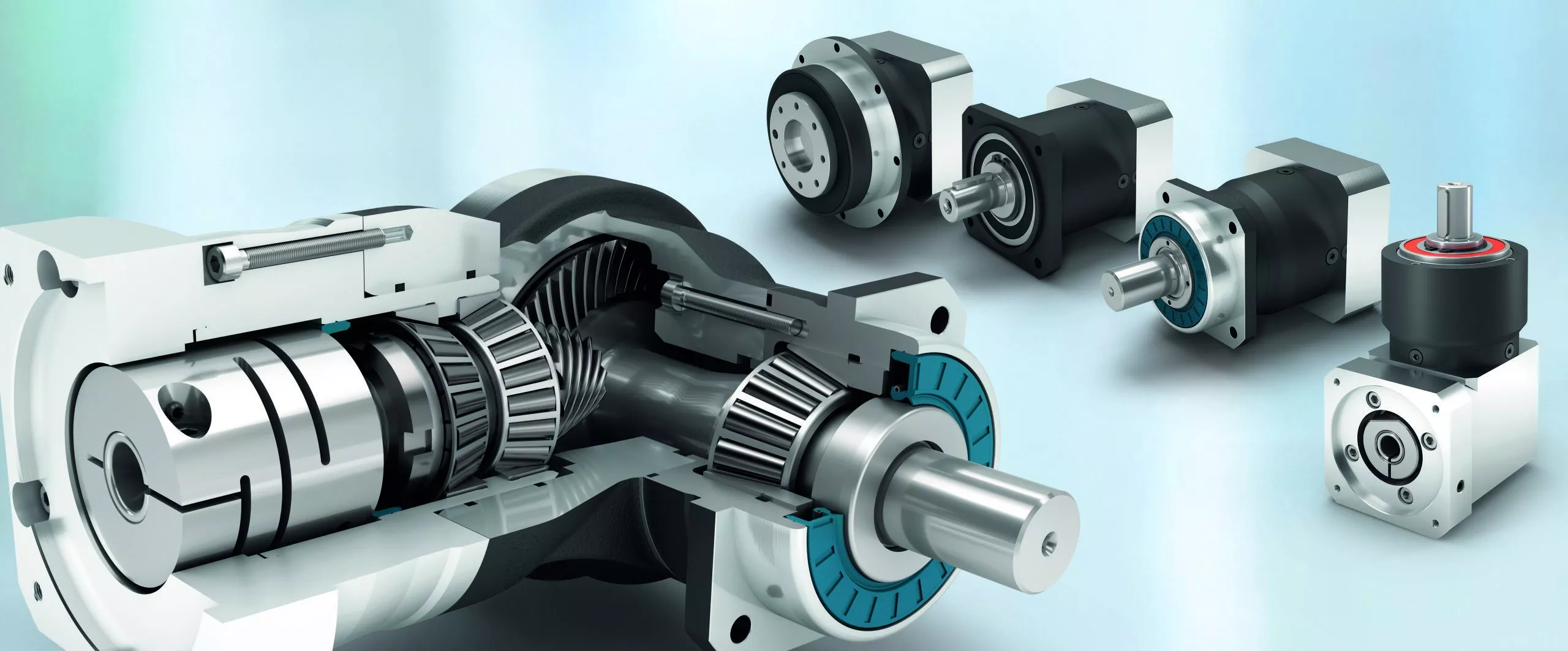

ZDR Helical Planetary Gearbox for Servo Motor

High precision planetary gearbox matched with serve motor, stepping motor are widely used. Lowest backlash<3"); High output torques; High efficiency(96%); Honed toothings; 22 ratios I=3, …., 512; Low noise(<65dB(A)); Any mounting position; Easy motor mounting; Life time lubrication; Figure diameters 40, 60, 80, 120, 160mm. More options.

Planetary gearbox:

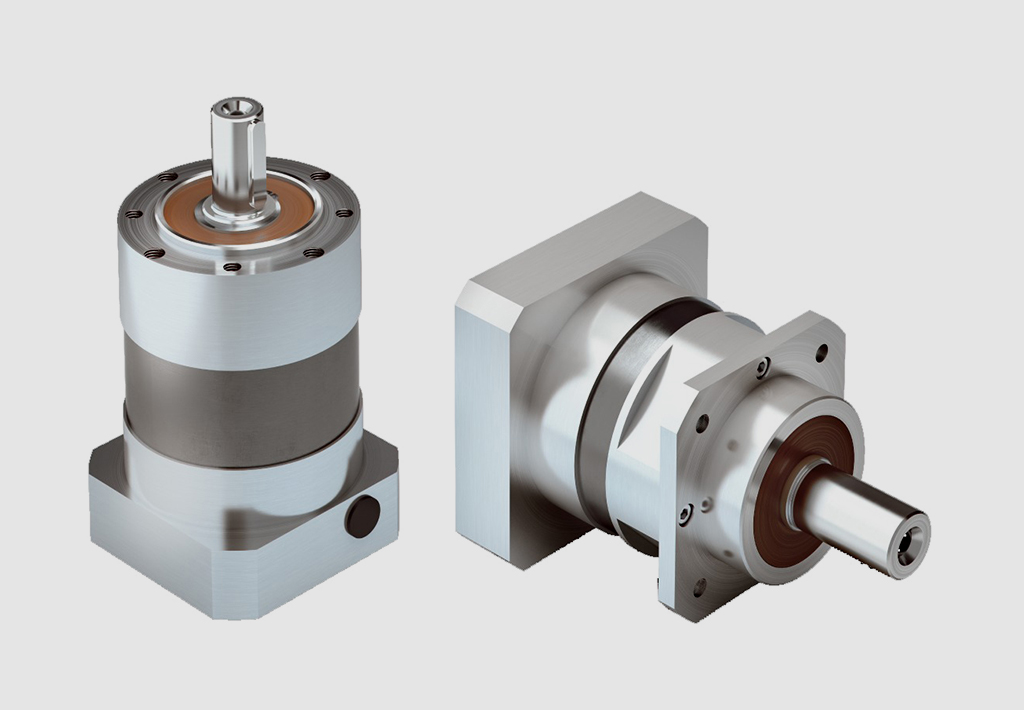

ZDE: Precision planetary-round flange output

ZDF: Precision planetary-square flange output

ZDWE: Precise planetary-right angle round flange output

ZDWF: Precise planetary-right angle square flange output

ZDS: Precise planetary-high rigidity, low back lash

| ZDE | round mounting flange |

| ZDWE | right angle input round mounting flange |

| ZDF | square mounting flange |

| ZDWF | right angle input square mounting flange |

| ZDS | high stiffness series |

| Gear Ratio: | |

| single stage | 3, 4, 5, 8, 10 |

| two stages | 9, 12, 15, 16, 20, 25, 32, 40, 64 |

| three stages | 60, 80, 100, 120, 160, 200, 256, 320, 512 |

Company Information

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Please contact us if you have detailed requests, thank you ! /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Power, Electronic |

|---|---|

| Phase: | Single |

| Core: | Shell-type Transformer |

| Cooling Method: | Oil-immersed Type Transformer |

| Winding Type: | Separated Winding Transformer |

| Certification: | UL, ISO9001, CCC, CCC, CE, UL. RoHS |

| Customization: |

Available

| Customized Request |

|---|

Handling Sudden Changes in Direction and Speed with Servo Gearboxes

Servo gearboxes are designed to handle sudden changes in direction and speed effectively, ensuring precise motion control even during dynamic operations. They employ several mechanisms to address these challenges:

1. Acceleration and Deceleration Profiles: Servo systems can be programmed with specific acceleration and deceleration profiles. This means that when a sudden change in speed or direction is commanded, the system can ramp up or down the speed smoothly, reducing the impact of sudden changes on the mechanical components.

2. Closed-Loop Control: Servo systems operate in a closed-loop configuration, where feedback sensors continuously monitor the actual position and speed of the system. When a sudden change is commanded, the controller can make real-time adjustments to ensure the system reaches the desired position accurately and smoothly.

3. Torque Control: Servo gearboxes are designed to provide high torque output even at low speeds. This is crucial for handling sudden changes in direction and speed, as the gearbox can deliver the required torque to quickly accelerate or decelerate the load.

4. Dynamic Response: Servo systems have fast dynamic response capabilities, which means they can quickly adapt to changes in input commands. This responsiveness allows the system to handle sudden changes in direction and speed without sacrificing accuracy or stability.

5. Electronic Damping: Some advanced servo systems incorporate electronic damping mechanisms that can be adjusted based on the application’s requirements. This feature helps dampen vibrations and oscillations that may occur during sudden changes in motion.

6. Overcurrent and Overvoltage Protection: Servo systems are equipped with protection mechanisms that detect excessive currents or voltages. If a sudden change in direction or speed causes abnormal loads or voltages, the system can take corrective actions to prevent damage.

Overall, servo gearboxes excel in handling sudden changes in direction and speed by leveraging their closed-loop control, high torque output, and fast dynamic response capabilities. These features allow them to provide accurate and reliable motion control in dynamic and rapidly changing operating conditions.

Precision of Gear Tooth Profiles in Servo Gearboxes

Manufacturers take several measures to ensure the precision of gear tooth profiles in servo gearboxes:

1. Advanced Manufacturing Processes: Manufacturers use advanced machining techniques such as CNC (Computer Numerical Control) machining and grinding to achieve high precision in gear tooth profiles. These processes allow for accurate shaping and finishing of the gear teeth.

2. Quality Materials: High-quality materials with consistent properties are selected for manufacturing gear components. This ensures uniformity in the gear teeth and minimizes variations that could affect precision.

3. Tight Tolerances: Manufacturers set tight tolerances for gear tooth dimensions, including pitch, profile, and helix angle. This helps to maintain precise engagement between gear teeth, reducing backlash and ensuring accurate motion control.

4. Quality Control: Rigorous quality control measures are implemented at various stages of the manufacturing process. This includes inspections, measurements, and tests to verify that gear tooth profiles meet the required specifications.

5. CNC Gear Inspection: Manufacturers use CNC gear inspection machines that can measure and analyze gear tooth profiles with high accuracy. These machines generate detailed reports about tooth geometry, ensuring compliance with design specifications.

6. Computer-Aided Design (CAD) and Simulation: Manufacturers use CAD software to design gear tooth profiles with precision. Simulation tools analyze how different factors, such as material properties and manufacturing processes, affect the final gear tooth shape.

7. Profile Corrections: In some cases, manufacturers apply profile corrections to optimize gear tooth profiles. These corrections compensate for any deviations that may occur during the manufacturing process.

8. Feedback from Application: Manufacturers often collaborate closely with end-users to gather feedback on the performance of gearboxes in real-world applications. This feedback helps refine the manufacturing process and improve the precision of gear tooth profiles.

The combination of advanced manufacturing techniques, strict quality control, and continuous improvement processes ensures that servo gearboxes maintain the precision required for accurate motion control in various applications.

Servo Gearbox: Function in Motion Control Systems

A servo gearbox is a specialized type of gearbox designed to work in conjunction with servo motors to achieve precise motion control in various applications. It functions as follows:

Motion Synchronization: A servo gearbox is used to synchronize the motion of a servo motor with the intended motion of a mechanical system. It ensures that the motor’s rotational output is accurately transmitted to the driven component.

Speed and Position Control: Servo gearboxes enable precise control over speed and position by converting the high-speed, low-torque output of a servo motor into a lower-speed, higher-torque output suitable for the specific application.

Reduction Ratio: The servo gearbox incorporates reduction stages to achieve the desired reduction ratio. This reduction allows the motor to provide higher torque while maintaining accurate speed control.

Backlash Minimization: High-precision servo gearboxes are designed to minimize backlash, which is the lost motion between input and output shafts. This is critical for accurate and responsive motion control.

High Efficiency: Servo gearboxes are designed for high efficiency to ensure that the majority of input power is effectively transferred to the output, reducing energy consumption.

Dynamic Response: Servo gearboxes enhance the dynamic response of motion control systems. They allow the servo motor to quickly start, stop, and change directions with minimal overshooting or oscillations.

Positioning Accuracy: By accurately converting the motor’s rotation into precise linear or angular movement, servo gearboxes ensure high positioning accuracy required in applications such as robotics, CNC machines, and automation systems.

Load Distribution: Servo gearboxes distribute the load evenly across gear teeth, enhancing the gearbox’s durability and minimizing wear.

Customization: Servo gearboxes are available in various sizes, reduction ratios, and configurations to suit different application requirements.

Overall, a servo gearbox is an integral component in motion control systems, allowing precise and efficient control over motion, speed, and position for a wide range of industrial applications.

editor by CX 2024-04-25