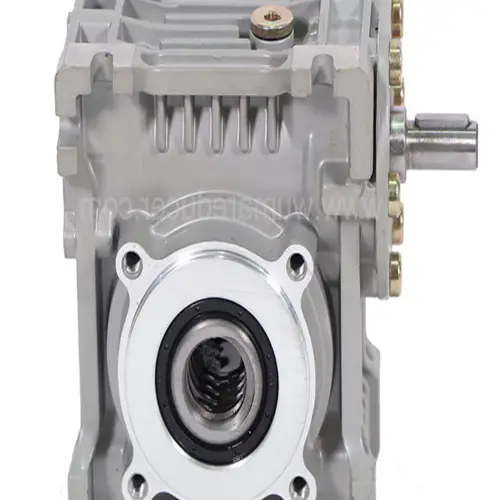

China’s Best Aluminium Custom Servo RV Motor Worm Wheel Right Angle Reduction Gearbox for ARB Air Compressors

This high-quality China-made aluminium custom servo RV motor worm wheel right angle reduction gearbox is a valuable addition to your ARB air compressor. With its excellent performance, durability, and efficient use, this gearbox is designed to provide the best user experience. It is ideal for various industrial machine applications such as ceramics, foodstuff, chemical, dyeing, and woodwork, among others.

Product Details

The WMRV gearbox model comes with varying ratios of 7.5, 10, 15, 20, 25, 30, 40, 50, 60, 80, and 100. The gearbox is available in blue (RAL5571) or silver-grey (K9149), or in custom colors upon request. The housing is made of aluminum alloy for size 25-90, while cast iron is used for size 110-185. The worm wheel is made of aluminum bronze or tin bronze, the worm shaft is 20CrMnTi, and the output shaft is steel-45#. The gearbox uses synthetic oil or worm gear oil as lubricant, and the IEC standard flange or customer request as the input flange.

Why Choose Us?

Our gearbox is manufactured with the highest standard materials and is designed to provide excellent performance, durability, and efficiency. We have a team of experts who ensure that our products meet the highest quality standards. We provide excellent customer service and offer customized solutions to meet your individual needs.

Customized Service

We welcome customers to send us their drawings and samples, and we will provide customized solutions that meet your requirements. Our company mainly supplies various industrial products such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, among others.

FAQs

Q1: How do I choose a gearbox that meets my requirement?

A1: You can refer to our catalogue to choose the gearbox or provide us with the technical information on the required output torque, output speed, and motor parameters, and we will help you choose the right gearbox.

Q2: What information should I provide before placing a purchase order?

A2: You should provide us with the gearbox type, ratio, input and output types, input flange, mounting position, motor information, housing color, purchase quantity, and any other special requirements.

Q3: What industries use your gearboxes?

A3: Our gearboxes are widely used in various industries such as textiles, food processing, beverages, chemical processing, escalators, automatic storage equipment, metallurgy, tobacco, environmental protection, logistics, and many others.

Q4: Do you sell motors?

A4: Yes, we have long-term partnerships with high-quality motor suppliers who can provide motors that meet high-quality standards.

Q5: What warranty do you offer?

A5: We offer a one-year warranty on all our gearboxes.

All the content of this page is from the Internet and is only meant to serve as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you require original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Servo Gearbox

1. High Precision: Servo gearboxes are known for their precise positioning capabilities, ensuring accurate movement control.

2. High Efficiency: These gearboxes exhibit high efficiency, resulting in reduced energy consumption and improved overall performance.

3. Low Noise: Servo gearboxes are designed to operate with minimal noise, ensuring a quiet working environment.

4. Compact Design: The compact nature of servo gearboxes allows for easy integration into various applications, even with limited space.

5. High Torque Capacity: Servo gearboxes can handle high torque loads, making them suitable for demanding applications.

6. Smooth Operation: These gearboxes offer smooth and stable operation, eliminating vibrations and ensuring precise motion control.

7. Wide Speed Range: Servo gearboxes are capable of operating at various speeds, providing flexibility for different applications.

Types and Characteristics of Servo Gearbox

There are different types of servo gearboxes available to cater to specific application requirements. Some common types include planetary, helical, and worm gearboxes.

Planetary Gearbox: This type of servo gearbox offers high torque capacity, compact size, and high efficiency. It is commonly used in robotics and automation industries.

Helical Gearbox: Helical servo gearboxes provide smooth and quiet operation, making them suitable for applications where noise reduction is crucial. They are often used in medical equipment and precision machinery.

Worm Gearbox: Worm gearboxes are known for their high gear ratios and self-locking capabilities. They find applications in various industries, including renewable energy and automotive.

Advantages of Servo Gearbox Made of Different Materials

Servo gearboxes can be made of various materials, each offering specific advantages for different applications.

Steel Gearboxes: Steel gearboxes provide excellent strength and durability, making them suitable for heavy-duty applications that require high load capacity.

Aluminum Gearboxes: Aluminum gearboxes are lightweight and have good heat dissipation properties, making them ideal for applications where weight reduction and thermal management are important.

Composite Gearboxes: Composite gearboxes combine the advantages of different materials, such as strength, lightweight, and corrosion resistance, making them suitable for various industries, including aerospace and automotive.

Application of Servo Gearbox in Various Fields

Servo gearboxes play a vital role in different industries, showcasing their value and importance.

Automotive: Servo gearboxes are widely used in automotive applications, such as power steering systems and transmission systems, ensuring precise control and efficient power transfer.

Robotics: Servo gearboxes are essential for robotic systems, providing accurate movement control and enabling smooth operation for various robotic applications.

Medical Equipment: Servo gearboxes are utilized in medical equipment, such as surgical robots and imaging devices, where precise motion control and reliability are critical.

Renewable Energy: Servo gearboxes are employed in wind turbines and solar tracking systems, ensuring efficient power generation by accurately adjusting the rotor and solar panel positions.

Aerospace: Servo gearboxes are crucial for aerospace applications, including aircraft flight control systems and landing gear mechanisms, enabling precise control and safe operation.

Future Development Trends and Opportunities

The future of servo gearboxes looks promising, with several development trends on the horizon.

1. Miniaturization: There is a growing demand for smaller and more compact servo gearboxes to meet the requirements of space-constrained applications.

2. Integration with IoT: The integration of servo gearboxes with Internet of Things (IoT) technology allows for remote monitoring, predictive maintenance, and improved overall system performance.

3. Enhanced Efficiency: Continuous advancements in materials and design techniques aim to improve the efficiency of servo gearboxes, resulting in reduced energy consumption and increased cost-effectiveness.

4. Customization: The ability to customize servo gearboxes according to specific application needs provides opportunities for tailored solutions and improved performance.

5. Automation and Industry 4.0: Servo gearboxes will continue to play a crucial role in automation and the implementation of Industry 4.0, ensuring precise motion control and enabling smart manufacturing processes.

Choosing a Suitable Servo Gearbox

When selecting a servo gearbox, various factors should be considered to ensure the best fit for the application.

1. Load Requirements: Analyze the torque and speed requirements of the application to select a gearbox capable of handling the specific load.

2. Ratio Selection: Determine the desired gear ratio based on the desired output speed and torque, considering the application’s requirements.

3. Type of Gearbox: Select the appropriate type of servo gearbox, such as planetary, helical, or worm, based on the application’s needs and constraints.

4. Environmental Factors: Consider environmental conditions, such as temperature, humidity, and dust, to choose a gearbox that can withstand and operate reliably in such conditions.

5. Maintenance and Durability: Assess the maintenance requirements and expected lifespan of the gearbox, ensuring it aligns with the application’s needs and operational demands.

In conclusion, servo gearboxes offer high precision, efficiency, and low noise operation. They come in different types, each with unique characteristics and advantages. The application of servo gearboxes spans various industries, demonstrating their value and importance. The future holds promising opportunities for servo gearbox development, driven by trends such as miniaturization and integration with IoT. When selecting a servo gearbox, factors like load requirements, ratio selection, gearbox type, and environmental factors should be carefully considered. By choosing the right servo gearbox, optimal performance and reliability can be achieved in various applications.

Author: Dream