Product Description

ZD 120mm High Precision Round Flange ZE Series Planetary Gearbox

Detailed Photos

Product Parameters

Related Gearbox

Other Related Products

Click here to find what you are looking for:

Company Profile

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Please contact us if you have detailed requests, thank you !

/* October 22, 2571 15:47:17 */(()=>{function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Handling Backlash and Ensuring Precise Positioning in Servo Gearboxes

Servo gearboxes play a critical role in minimizing backlash and ensuring precise positioning in motion control systems:

1. Reduced Backlash Gearing: Many servo gearboxes utilize reduced backlash gearing technology. This involves designing gears with tighter tolerances and improved meshing profiles, resulting in minimal play between gear teeth. This reduces or eliminates backlash, which is essential for accurate motion control.

2. Preloading: Some servo gearboxes employ preloading mechanisms to remove any gaps between gears. By applying a controlled axial load to the gears, the meshing teeth remain in constant contact, eliminating backlash and enhancing precision.

3. Stiffness and Rigidity: Servo gearboxes are designed to be stiff and rigid, which helps minimize elastic deformation under load. This stiffness prevents gear teeth from deflecting, reducing the potential for backlash and maintaining accurate positioning.

4. High Gear Meshing Quality: The manufacturing process of servo gearboxes focuses on producing high-quality gears with precise tooth profiles and minimal manufacturing variations. This ensures consistent and smooth gear meshing, minimizing the likelihood of backlash.

5. Closed-Loop Control: Combining servo gearboxes with closed-loop control systems allows for real-time feedback on position and speed. Any deviation from the desired position can be quickly corrected by adjusting the motor’s output, compensating for any inherent backlash and ensuring precise positioning.

6. Advanced Gear Coatings: Some servo gearboxes incorporate advanced gear coatings or treatments that improve the meshing characteristics and reduce friction. This contributes to smoother gear engagement and minimizes backlash effects.

7. Inertia Matching: Properly matching the inertia of the load to the servo motor and gearbox combination reduces the likelihood of overshooting or oscillations during positioning. Accurate inertia matching enhances the control system’s ability to maintain precise positioning.

Servo gearboxes’ ability to handle backlash and ensure precise positioning is crucial for applications that require high accuracy, such as robotics, CNC machines, and automated manufacturing processes. By employing advanced design techniques and technologies, servo gearboxes contribute to achieving repeatable and accurate motion control.

Disadvantages and Limitations of Using Servo Gear Systems

Servo gear systems offer numerous benefits for precise motion control, but they also come with certain disadvantages and limitations:

1. Cost: Servo gear systems can be more expensive than traditional gearbox solutions. The combination of high-precision components, advanced electronics, and closed-loop control mechanisms can result in higher upfront costs.

2. Complexity: Servo gear systems are complex, requiring expertise in programming, tuning, and integrating the components. Setting up and fine-tuning the system can be time-consuming, especially for applications with intricate motion profiles.

3. Maintenance: The complex nature of servo gear systems can lead to increased maintenance requirements. Regular maintenance, including calibration and monitoring of sensors, is essential to ensure optimal performance and accuracy.

4. Sensitivity to Environmental Factors: Servo systems can be sensitive to environmental conditions such as temperature, humidity, and vibration. Extreme variations in these factors can impact the system’s performance and accuracy.

5. Power Consumption: Servo systems can consume more power compared to other motion control solutions. This is due to the continuous monitoring, feedback processing, and control algorithms that are essential for precise motion control.

6. Size and Weight: In some cases, servo gear systems can be larger and heavier than traditional gearbox setups, which can impact the overall design and space requirements of the machinery or equipment.

7. Overkill for Some Applications: Not all applications require the high precision and capabilities offered by servo gear systems. In simpler applications, the added complexity and cost may not be justified.

8. Compatibility Challenges: Integrating servo gear systems with existing equipment or machinery can be challenging, especially if the components are not designed to work together seamlessly.

While servo gear systems provide exceptional precision and control, it’s important to carefully evaluate the specific requirements of the application and consider the associated disadvantages and limitations before choosing this solution.

Benefits of Using a Servo Gearbox for Precise Motion Control

Servo gearboxes offer several advantages when it comes to achieving precise motion control in various applications:

1. Accuracy: Servo gearboxes provide exceptional accuracy in speed and position control, making them suitable for applications that require tight tolerances and precise movements.

2. Low Backlash: These gearboxes are designed to minimize backlash, which is essential for eliminating lost motion and ensuring accurate positioning.

3. High Torque Density: Servo gearboxes offer a high torque-to-size ratio, allowing them to handle significant loads while maintaining a compact footprint.

4. Dynamic Performance: They excel in dynamic performance, enabling rapid changes in speed and direction with minimal overshoot or settling time.

5. Responsiveness: Servo gearboxes respond quickly to control signals, making them ideal for applications that require rapid adjustments and changes in direction.

6. Smooth Operation: These gearboxes provide smooth and precise movement, critical for applications like robotics, where jerky or uneven motion can lead to inaccuracies or damage.

7. Reduces Maintenance: The accuracy and durability of servo gearboxes can reduce wear and tear on other components, leading to lower maintenance requirements.

8. Improved Efficiency: Servo gearboxes offer high efficiency in power transmission, contributing to energy savings and minimizing heat generation.

9. Customization: They can be tailored to specific application needs, including factors like reduction ratios, mounting options, and feedback compatibility.

10. Versatility: Servo gearboxes find application in various industries, including robotics, CNC machining, medical equipment, and automation.

Overall, the benefits of using a servo gearbox for precise motion control make them an essential component in applications that demand accuracy, responsiveness, and reliable performance.

editor by lmc 2024-11-29

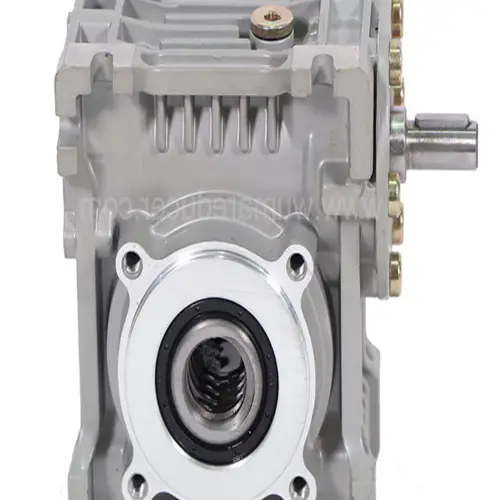

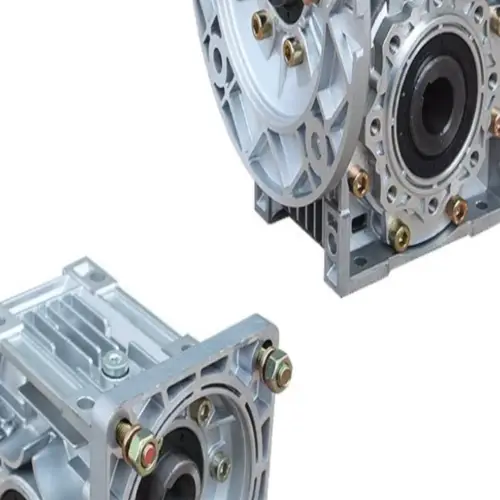

China high quality Helical Worm Gearbox Coupled with Servo Motor Flange Output Torque 1970nm 12v air compressor

China High Quality Helical Worm Gearbox Coupled with Servo Motor Flange Output Torque 1970nm 12V Air Compressor

The China High Quality Helical Worm Gearbox Coupled with Servo Motor Flange Output Torque 1970nm 12V Air Compressor is a powerful and highly efficient industrial helical gearbox. This gearbox features a high modular design that allows for flexible mounting mode, making it suitable for a wide range of industry applications. Its integrated casting housing ensures compact dimensions, stable transmitting, and low noise levels. It has perfect oil leakage prevention and good sealing, making it a reliable gearbox for various industrial needs.

Product Description

The SA Series Helical Worm Gearbox comes with a 1.5kw Explosion Proof Motor. It has various input and output configurations, including direct motor coupled, with IEC B5/B14 motor flange, with IEC B5/B14 motor mounted, with CHINAMFG input shaft, CHINAMFG output shaft, CHINAMFG output shaft with flange, hollow output shaft, and hollow output shaft with flange. The variants of the Helical Worm Gear Unit Series S / SF / SA / SAF are foot- or flange-mounted, with B5 or B14 flange-mounted, CHINAMFG shaft or hollow shaft, and hollow shaft with keyed connection, shrink disk, splined hollow shaft, or Torque Arm.

Technical Data:

| Housing material | Cast iron/Ductile iron |

| Housing hardness | HBS190-240 |

| Gear material | 20CrMnTi alloy steel |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Input / Output shaft material | 42CrMo alloy steel |

| Input / Output shaft hardness | HRC25~30 |

| Machining precision of gears | accurate grinding, 6~5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | tempering, cementiting, quenching, etc. |

| Efficiency | 94%~96% (depends on the transmission stage) |

| Noise (MAX) | 60~68dB |

| Temp. rise (MAX) | 40°C |

| Temp. rise (Oil)(MAX) | 50°C |

| Vibration | ≤20µm |

| Backlash | ≤20Arcmin |

| Brand of bearings | China top brand bearing, HRB/LYC/ZWZ/C&U. Or other brands requested, NSK. |

| Brand of oil seal | NAK — ZheJiang or other brands requested |

Features

High modular design, flexible mounting mode. Integrated casting housing, compact dimension, stable transmitting, and low noise level. Perfect oil leakage preventing makes the good sealings and can be used in a wide range of industries. Advanced gear grinding and modified profile, high loading support, and more safe operation. High efficiency and save power. Save cost and low maintenance.

Specification

| Model | Shaft Dia.

mm |

Horizontal Center Height mm | External Flange Dia.

mm |

Power

(kw) |

Ratio

(i) |

Nominal Torque

(Nm) |

|

| CHINAMFG Shaft | Hollow Shaft | ||||||

| S/SF/SA/SAF37 | ф20 | ф20 | 88 | 0.12-0.55 | 24-204 | 100 | |

| S/SF/SA/SAF47 | ф25 | ф30 / ф25 | 100 | 160 | 0.18-0.75 | 24-204 | 150 |

| S/SF/SA/SAF57 | ф30 | ф35 / ф30 | 112 | 200 | 0.75-1.5 | 24-204 | 250 |

| S/SF/SA/SAF67 | ф35 | ф45 /ф40 | 140 | 200 | 0.75-3 | 24-285 | 460 |

| S/SF/SA/SAF77 | ф45 | ф60 / ф50 | 180 | 250 | 0.75-7.5 | 24-385 | 1200 |

| S/SF/SA/SAF87 | ф60 | ф70 / ф60 | 225 | 350 | 1.1-11 | 24-389 | 2000 |

| S/SF/SA/SAF97 | ф70 | ф90 / ф70 | 280 | 450 | 1.5-18.5 | 24-389 | 3500 |

FAQ

1. What are the available input and output configurations for the SA Series Helical Worm Gearbox?

The SA Series Helical Worm Gearbox comes with various input and output configurations, including direct motor coupled, with IEC B5/B14 motor flange, with IEC B5/B14 motor mounted, with CHINAMFG input shaft, CHINAMFG output shaft, CHINAMFG output shaft flange, hollow output shaft, and hollow output shaft with flange.

2. What are the technical specifications of the China High Quality Helical Worm Gearbox Coupled with Servo Motor Flange Output Torque 1970nm 12V Air Compressor?

The technical specifications of the China High Quality Helical Worm Gearbox Coupled with Servo Motor Flange Output Torque 1970nm 12V Air Compressor include housing material, housing hardness, gear material, surface hardness of gears, gear core hardness, input/output shaft material and hardness, machining precision of gears, lubricating oil, heat treatment, efficiency, noise level, temperature rise, vibration, and backlash.

3. What are the features of the China High Quality Helical Worm Gearbox Coupled with Servo Motor Flange Output Torque 1970nm 12V Air Compressor?

The China High Quality Helical Worm Gearbox Coupled with Servo Motor Flange Output Torque 1970nm 12V Air Compressor has a high modular design, flexible mounting mode, integrated casting housing, compact dimension, stable transmitting, low noise level, perfect oil leakage prevention, advanced gear grinding and modified profile, high loading support, safe operation, high efficiency, and low maintenance.

4. What is the lead time for the China High Quality Helical Worm Gearbox Coupled with Servo Motor Flange Output Torque 1970nm 12V Air Compressor?

For a 20′ container, it takes 25-30 workdays for RV series worm gearbox and 35-40 workdays for helical gearmotors.

5. What other products does the company offer besides the China High Quality Helical Worm Gearbox Coupled with Servo Motor Flange Output Torque 1970nm 12V Air Compressor?

Our company offers various products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc. Customers are welcome to customize drawings and samples for their specific needs.

All the content of this page is from the Internet and is only meant to serve as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you require original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Servo Gearbox

1. High Precision: Servo gearboxes are known for their precise positioning capabilities, ensuring accurate movement control.

2. High Efficiency: These gearboxes exhibit high efficiency, resulting in reduced energy consumption and improved overall performance.

3. Low Noise: Servo gearboxes are designed to operate with minimal noise, ensuring a quiet working environment.

4. Compact Design: The compact nature of servo gearboxes allows for easy integration into various applications, even with limited space.

5. High Torque Capacity: Servo gearboxes can handle high torque loads, making them suitable for demanding applications.

6. Smooth Operation: These gearboxes offer smooth and stable operation, eliminating vibrations and ensuring precise motion control.

7. Wide Speed Range: Servo gearboxes are capable of operating at various speeds, providing flexibility for different applications.

Types and Characteristics of Servo Gearbox

There are different types of servo gearboxes available to cater to specific application requirements. Some common types include planetary, helical, and worm gearboxes.

Planetary Gearbox: This type of servo gearbox offers high torque capacity, compact size, and high efficiency. It is commonly used in robotics and automation industries.

Helical Gearbox: Helical servo gearboxes provide smooth and quiet operation, making them suitable for applications where noise reduction is crucial. They are often used in medical equipment and precision machinery.

Worm Gearbox: Worm gearboxes are known for their high gear ratios and self-locking capabilities. They find applications in various industries, including renewable energy and automotive.

Advantages of Servo Gearbox Made of Different Materials

Servo gearboxes can be made of various materials, each offering specific advantages for different applications.

Steel Gearboxes: Steel gearboxes provide excellent strength and durability, making them suitable for heavy-duty applications that require high load capacity.

Aluminum Gearboxes: Aluminum gearboxes are lightweight and have good heat dissipation properties, making them ideal for applications where weight reduction and thermal management are important.

Composite Gearboxes: Composite gearboxes combine the advantages of different materials, such as strength, lightweight, and corrosion resistance, making them suitable for various industries, including aerospace and automotive.

Application of Servo Gearbox in Various Fields

Servo gearboxes play a vital role in different industries, showcasing their value and importance.

Automotive: Servo gearboxes are widely used in automotive applications, such as power steering systems and transmission systems, ensuring precise control and efficient power transfer.

Robotics: Servo gearboxes are essential for robotic systems, providing accurate movement control and enabling smooth operation for various robotic applications.

Medical Equipment: Servo gearboxes are utilized in medical equipment, such as surgical robots and imaging devices, where precise motion control and reliability are critical.

Renewable Energy: Servo gearboxes are employed in wind turbines and solar tracking systems, ensuring efficient power generation by accurately adjusting the rotor and solar panel positions.

Aerospace: Servo gearboxes are crucial for aerospace applications, including aircraft flight control systems and landing gear mechanisms, enabling precise control and safe operation.

Future Development Trends and Opportunities

The future of servo gearboxes looks promising, with several development trends on the horizon.

1. Miniaturization: There is a growing demand for smaller and more compact servo gearboxes to meet the requirements of space-constrained applications.

2. Integration with IoT: The integration of servo gearboxes with Internet of Things (IoT) technology allows for remote monitoring, predictive maintenance, and improved overall system performance.

3. Enhanced Efficiency: Continuous advancements in materials and design techniques aim to improve the efficiency of servo gearboxes, resulting in reduced energy consumption and increased cost-effectiveness.

4. Customization: The ability to customize servo gearboxes according to specific application needs provides opportunities for tailored solutions and improved performance.

5. Automation and Industry 4.0: Servo gearboxes will continue to play a crucial role in automation and the implementation of Industry 4.0, ensuring precise motion control and enabling smart manufacturing processes.

Choosing a Suitable Servo Gearbox

When selecting a servo gearbox, various factors should be considered to ensure the best fit for the application.

1. Load Requirements: Analyze the torque and speed requirements of the application to select a gearbox capable of handling the specific load.

2. Ratio Selection: Determine the desired gear ratio based on the desired output speed and torque, considering the application’s requirements.

3. Type of Gearbox: Select the appropriate type of servo gearbox, such as planetary, helical, or worm, based on the application’s needs and constraints.

4. Environmental Factors: Consider environmental conditions, such as temperature, humidity, and dust, to choose a gearbox that can withstand and operate reliably in such conditions.

5. Maintenance and Durability: Assess the maintenance requirements and expected lifespan of the gearbox, ensuring it aligns with the application’s needs and operational demands.

In conclusion, servo gearboxes offer high precision, efficiency, and low noise operation. They come in different types, each with unique characteristics and advantages. The application of servo gearboxes spans various industries, demonstrating their value and importance. The future holds promising opportunities for servo gearbox development, driven by trends such as miniaturization and integration with IoT. When selecting a servo gearbox, factors like load requirements, ratio selection, gearbox type, and environmental factors should be carefully considered. By choosing the right servo gearbox, optimal performance and reliability can be achieved in various applications.

Author: Dream

China manufacturer Desboer Nhk Series 115-P1 Double Stage High Precision Planetary Gearbox Used for Servo Motor Siemens, Yaskawa, ABB and So on arb air compressor

China Manufacturer Desboer NHK Series 115-P1 Double Stage High Precision Planetary Gearbox

Product Description

The Desboer NHK Series 115-P1 Double Stage High Precision Planetary Gearbox is an economic version with a round body design. It features an integrated sun gear motor shaft design and high-strength deep groove ball bearings. This gearbox is widely used in various industries including injection molding robots, food packaging machines, filling machine lines, labeling machines, appliance production lines, and non-metal processing equipment.

Applicable Industries:

- Injection molding robots

- Food packaging machines

- Filling machine lines

- Labeling machines

- Appliance production lines

- Non-metal processing equipment

Product Features:

- High precision and low noise

- Lightweight design

- Integrated design concept with high-strength bearings for durability and efficiency

- Multiple output options such as shaft output, flange, and gear

- Backlash ranging from 1 arc minute to 3 arc minutes

- Reduction ratios ranging from 3 to 100

- Frame design that increases torque and optimizes power transmission

- Optimized selection of oil seals to reduce friction and enhance transmission efficiency

- Protection class IP65

- 2-year warranty

Our Advantages

- High precision

- Low noise

- Lightweight

Detailed Photos

Product Parameters

| Frame | Model |

|---|

| Housing material | HT200 high-strength cast iron(EWR37, EWR47, EWR57, EWR67, EWR77, EWR87) |

| Housing material | HT250 High strength cast iron(EWR97, EWR 107, EWR137, EWR147, EWR167) |

| Gear material | 20CrMnTi |

| Gear Surface&hardness | HRC58°-62° |

| Gear core hardness | HRC33°-78° |

| Input/Output shaft material | 40Cr |

| Gear Machining precision | Accurate grinding 6-5 grade |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | Up to 92% |

| Noise(Max) | 60-67dB |

| Installation type | Foot mounted, flange mounted |

| Output type | Solid shaft |

| Bearing brand | NSK, SKF, HRB, ZWZ etc |

| Oil seal brand | NAK, KSK etc |

| Lubricant | VG220 |

| Motor | IP55, F class |

| Motor shaft | 40Cr, Carburizing, Quenching etc |

| Warranty | 12months |

| Color | Blue, Grey |

Installation Instructions

Packaging & Shipping

Company Profile

FAQ

- Can you make as per customer drawing?

- Are you a factory or trading company?

- What’s your MOQ?

- What’s your quality control system?

- What’s your production time?

- What’s your payment terms?

- What’s your package?

A: Yes, we offer customized service for customers.

A: We are a manufacturer in ZheJiang, China.

A: One piece.

A: We are certified with CE, CCC, ISO 9001. We have our own independent QC team and advanced equipments to ensure quality from material purchasing till goods delivery.

A: 15-35 working days after receiving payment.

A: T/T, 30% payment in advance, 70% balance payment should be paid before shipping.

A: In wooden box packaging.

Our company mainly supplies various products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc. We are dedicated to providing high-quality products, preferential prices, and considerate services. Customers are welcome to customize drawings and samples.

All the content of this page is from the Internet and is only meant to serve as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you require original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Servo Gearbox

1. High Precision: Servo gearboxes are known for their precise positioning capabilities, ensuring accurate movement control.

2. High Efficiency: These gearboxes exhibit high efficiency, resulting in reduced energy consumption and improved overall performance.

3. Low Noise: Servo gearboxes are designed to operate with minimal noise, ensuring a quiet working environment.

4. Compact Design: The compact nature of servo gearboxes allows for easy integration into various applications, even with limited space.

5. High Torque Capacity: Servo gearboxes can handle high torque loads, making them suitable for demanding applications.

6. Smooth Operation: These gearboxes offer smooth and stable operation, eliminating vibrations and ensuring precise motion control.

7. Wide Speed Range: Servo gearboxes are capable of operating at various speeds, providing flexibility for different applications.

Types and Characteristics of Servo Gearbox

There are different types of servo gearboxes available to cater to specific application requirements. Some common types include planetary, helical, and worm gearboxes.

Planetary Gearbox: This type of servo gearbox offers high torque capacity, compact size, and high efficiency. It is commonly used in robotics and automation industries.

Helical Gearbox: Helical servo gearboxes provide smooth and quiet operation, making them suitable for applications where noise reduction is crucial. They are often used in medical equipment and precision machinery.

Worm Gearbox: Worm gearboxes are known for their high gear ratios and self-locking capabilities. They find applications in various industries, including renewable energy and automotive.

Advantages of Servo Gearbox Made of Different Materials

Servo gearboxes can be made of various materials, each offering specific advantages for different applications.

Steel Gearboxes: Steel gearboxes provide excellent strength and durability, making them suitable for heavy-duty applications that require high load capacity.

Aluminum Gearboxes: Aluminum gearboxes are lightweight and have good heat dissipation properties, making them ideal for applications where weight reduction and thermal management are important.

Composite Gearboxes: Composite gearboxes combine the advantages of different materials, such as strength, lightweight, and corrosion resistance, making them suitable for various industries, including aerospace and automotive.

Application of Servo Gearbox in Various Fields

Servo gearboxes play a vital role in different industries, showcasing their value and importance.

Automotive: Servo gearboxes are widely used in automotive applications, such as power steering systems and transmission systems, ensuring precise control and efficient power transfer.

Robotics: Servo gearboxes are essential for robotic systems, providing accurate movement control and enabling smooth operation for various robotic applications.

Medical Equipment: Servo gearboxes are utilized in medical equipment, such as surgical robots and imaging devices, where precise motion control and reliability are critical.

Renewable Energy: Servo gearboxes are employed in wind turbines and solar tracking systems, ensuring efficient power generation by accurately adjusting the rotor and solar panel positions.

Aerospace: Servo gearboxes are crucial for aerospace applications, including aircraft flight control systems and landing gear mechanisms, enabling precise control and safe operation.

Future Development Trends and Opportunities

The future of servo gearboxes looks promising, with several development trends on the horizon.

1. Miniaturization: There is a growing demand for smaller and more compact servo gearboxes to meet the requirements of space-constrained applications.

2. Integration with IoT: The integration of servo gearboxes with Internet of Things (IoT) technology allows for remote monitoring, predictive maintenance, and improved overall system performance.

3. Enhanced Efficiency: Continuous advancements in materials and design techniques aim to improve the efficiency of servo gearboxes, resulting in reduced energy consumption and increased cost-effectiveness.

4. Customization: The ability to customize servo gearboxes according to specific application needs provides opportunities for tailored solutions and improved performance.

5. Automation and Industry 4.0: Servo gearboxes will continue to play a crucial role in automation and the implementation of Industry 4.0, ensuring precise motion control and enabling smart manufacturing processes.

Choosing a Suitable Servo Gearbox

When selecting a servo gearbox, various factors should be considered to ensure the best fit for the application.

1. Load Requirements: Analyze the torque and speed requirements of the application to select a gearbox capable of handling the specific load.

2. Ratio Selection: Determine the desired gear ratio based on the desired output speed and torque, considering the application’s requirements.

3. Type of Gearbox: Select the appropriate type of servo gearbox, such as planetary, helical, or worm, based on the application’s needs and constraints.

4. Environmental Factors: Consider environmental conditions, such as temperature, humidity, and dust, to choose a gearbox that can withstand and operate reliably in such conditions.

5. Maintenance and Durability: Assess the maintenance requirements and expected lifespan of the gearbox, ensuring it aligns with the application’s needs and operational demands.

In conclusion, servo gearboxes offer high precision, efficiency, and low noise operation. They come in different types, each with unique characteristics and advantages. The application of servo gearboxes spans various industries, demonstrating their value and importance. The future holds promising opportunities for servo gearbox development, driven by trends such as miniaturization and integration with IoT. When selecting a servo gearbox, factors like load requirements, ratio selection, gearbox type, and environmental factors should be carefully considered. By choosing the right servo gearbox, optimal performance and reliability can be achieved in various applications.

Author: Dream

China Professional CHINAMFG Universal Economical Right-Angle Output Planetary Gearbox, high torque, specially equipped with servo motor with high quality

China Professional CHINAMFG Universal Economical Right-Angle Output Planetary Gearbox: High Torque, Specially Equipped with Servo Motor

The China Professional CHINAMFG Universal Economical Right-Angle Output Planetary Gearbox is a high-quality gear system designed to provide high torque and efficiency in various industrial applications. Equipped with a servo motor, this gearbox offers precise control and reliable performance.

Product Description

The PLDR/PLDR+90 Level 2 gearbox is a versatile solution for your power transmission needs. With a reduction ratio ranging from 15 to 100, it allows for efficient torque conversion to suit different applications. The rated output torque, ranging from 110 Nm to 145 Nm, ensures reliable power delivery.

Emergency Braking Torque

The gearbox is specially designed to withstand emergency braking conditions. With a braking torque of 3 times the rated output torque, this gearbox ensures safe operation even in critical situations.

Maximum Input Speed and Return Clearance

The PLDR/PLDR+90 Level 2 gearbox can handle a maximum input speed of 6000 rpm, allowing for high-speed applications. Additionally, it offers a maximum return clearance of PLDR60≤8ARCMIN, PLDR+60≤5ARCMIN, and Custom-made≤3ARCMIN, ensuring precise and smooth operation.

Features and Benefits

- Very high power density, with a torque increase of 40% compared to conventional gearboxes

- Easy motor installation with optional length compensation

- Flexible installation options, allowing for vertical, horizontal, and up or down installation

- High positioning accuracy, with a return clearance of less than arc minutes

- Stable operation and low running noise (less than 50dB-A) due to helical gear meshing

- World-leading life expectancy, thanks to optimized raw materials and mechanism seal rings

With our CHINAMFG Precision Planetary Gearbox, you can expect exceptional performance and durability for your industrial applications. Whether it’s robotics, printing machines, machine tools, food and packaging machinery, or textile machines, our gearbox will meet your requirements with its high precision, stability, and efficiency.

At CHINAMFG, we are committed to providing high-quality products, competitive prices, and excellent customer service. In addition to the Universal Economical Right-Angle Output Planetary Gearbox, we also offer a wide range of industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary

All the content of this page is from the Internet and is only meant to serve as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you require original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Servo Gearbox

1. High Precision: Servo gearboxes are known for their precise positioning capabilities, ensuring accurate movement control.

2. High Efficiency: These gearboxes exhibit high efficiency, resulting in reduced energy consumption and improved overall performance.

3. Low Noise: Servo gearboxes are designed to operate with minimal noise, ensuring a quiet working environment.

4. Compact Design: The compact nature of servo gearboxes allows for easy integration into various applications, even with limited space.

5. High Torque Capacity: Servo gearboxes can handle high torque loads, making them suitable for demanding applications.

6. Smooth Operation: These gearboxes offer smooth and stable operation, eliminating vibrations and ensuring precise motion control.

7. Wide Speed Range: Servo gearboxes are capable of operating at various speeds, providing flexibility for different applications.

Types and Characteristics of Servo Gearbox

There are different types of servo gearboxes available to cater to specific application requirements. Some common types include planetary, helical, and worm gearboxes.

Planetary Gearbox: This type of servo gearbox offers high torque capacity, compact size, and high efficiency. It is commonly used in robotics and automation industries.

Helical Gearbox: Helical servo gearboxes provide smooth and quiet operation, making them suitable for applications where noise reduction is crucial. They are often used in medical equipment and precision machinery.

Worm Gearbox: Worm gearboxes are known for their high gear ratios and self-locking capabilities. They find applications in various industries, including renewable energy and automotive.

Advantages of Servo Gearbox Made of Different Materials

Servo gearboxes can be made of various materials, each offering specific advantages for different applications.

Steel Gearboxes: Steel gearboxes provide excellent strength and durability, making them suitable for heavy-duty applications that require high load capacity.

Aluminum Gearboxes: Aluminum gearboxes are lightweight and have good heat dissipation properties, making them ideal for applications where weight reduction and thermal management are important.

Composite Gearboxes: Composite gearboxes combine the advantages of different materials, such as strength, lightweight, and corrosion resistance, making them suitable for various industries, including aerospace and automotive.

Application of Servo Gearbox in Various Fields

Servo gearboxes play a vital role in different industries, showcasing their value and importance.

Automotive: Servo gearboxes are widely used in automotive applications, such as power steering systems and transmission systems, ensuring precise control and efficient power transfer.

Robotics: Servo gearboxes are essential for robotic systems, providing accurate movement control and enabling smooth operation for various robotic applications.

Medical Equipment: Servo gearboxes are utilized in medical equipment, such as surgical robots and imaging devices, where precise motion control and reliability are critical.

Renewable Energy: Servo gearboxes are employed in wind turbines and solar tracking systems, ensuring efficient power generation by accurately adjusting the rotor and solar panel positions.

Aerospace: Servo gearboxes are crucial for aerospace applications, including aircraft flight control systems and landing gear mechanisms, enabling precise control and safe operation.

Future Development Trends and Opportunities

The future of servo gearboxes looks promising, with several development trends on the horizon.

1. Miniaturization: There is a growing demand for smaller and more compact servo gearboxes to meet the requirements of space-constrained applications.

2. Integration with IoT: The integration of servo gearboxes with Internet of Things (IoT) technology allows for remote monitoring, predictive maintenance, and improved overall system performance.

3. Enhanced Efficiency: Continuous advancements in materials and design techniques aim to improve the efficiency of servo gearboxes, resulting in reduced energy consumption and increased cost-effectiveness.

4. Customization: The ability to customize servo gearboxes according to specific application needs provides opportunities for tailored solutions and improved performance.

5. Automation and Industry 4.0: Servo gearboxes will continue to play a crucial role in automation and the implementation of Industry 4.0, ensuring precise motion control and enabling smart manufacturing processes.

Choosing a Suitable Servo Gearbox

When selecting a servo gearbox, various factors should be considered to ensure the best fit for the application.

1. Load Requirements: Analyze the torque and speed requirements of the application to select a gearbox capable of handling the specific load.

2. Ratio Selection: Determine the desired gear ratio based on the desired output speed and torque, considering the application’s requirements.

3. Type of Gearbox: Select the appropriate type of servo gearbox, such as planetary, helical, or worm, based on the application’s needs and constraints.

4. Environmental Factors: Consider environmental conditions, such as temperature, humidity, and dust, to choose a gearbox that can withstand and operate reliably in such conditions.

5. Maintenance and Durability: Assess the maintenance requirements and expected lifespan of the gearbox, ensuring it aligns with the application’s needs and operational demands.

In conclusion, servo gearboxes offer high precision, efficiency, and low noise operation. They come in different types, each with unique characteristics and advantages. The application of servo gearboxes spans various industries, demonstrating their value and importance. The future holds promising opportunities for servo gearbox development, driven by trends such as miniaturization and integration with IoT. When selecting a servo gearbox, factors like load requirements, ratio selection, gearbox type, and environmental factors should be carefully considered. By choosing the right servo gearbox, optimal performance and reliability can be achieved in various applications.

Author: Dream

China Best Sales CHINAMFG Precision Planetary Gearbox Planetary Gear Reducer Servo Gearbox air compressor oil

China Best Sales CHINAMFG Precision Planetary Gearbox Planetary Gear Reducer Servo Gearbox air compressor oil

Product Description

Aokman Precision Planetary Gearbox planetary gear reducer servo gearbox

Components:

1. Gearbox Housing & Flange: Aluminum-alloy Die Casting ADC12

2. Gear set: Precision Planetary Gear Set

Ring Gears: 40Cr

Planetary Gears: 20CrMnTi, Surface Hardness HRC58~62, Inner Hardness HRC33~40

3. Input Configurations: Keyed Hollow Shaft with Motor Adaptor

4. Output Configurations: Keyed CHINAMFG Shaft Output

keyless Solid Shaft Output

5. Applicable Motors:

Servo Motors, Stepper Motors

Features:

1. AOKMAN high precision planetary gearboxes including a full series of inline(linear) and right angle precision planetary gearboxes

2. High precision, high dynamic, low backlash

3. Up to 3 optional backlash: Ultra Precision Backlash, High Precision Backlash, Standard Backlash

4. Superior performance for precision industrial automation and servo applications

| series | Stage | Models | Ratio | Rated Torque | Rated input Speed | Max input Speed | Backlash | Efficiency |

| PPG(Linear) | 1 | PPG040 | 3,4,5,7,8,10 | 9N.m~423N.m | 25,003,000,360,040,000,000 | 3600 | ≤10 arcmin | ≥97% |

| PPG060 | 4800 | |||||||

| PPG080 | 6000 | |||||||

| PPG120 | 8000 | |||||||

| PPG160 | ||||||||

| 2 | PPG040 | 12,15,20,25,30,35,40,50,70,100 | 9N.m~423N.m | 25,003,000,360,040,000,000 | 3600, | ≤15 arcmin | ≥94% | |

| PPG060 | 4800 | |||||||

| PPG080 | 6000 | |||||||

| PPG120 | 8000 | |||||||

| PPG160 |

1. More than 35 years experience in R&D and manufacturing, export gear motors & industrial gearboxes.

2. Standardization of the gearbox series

3. Strong design capability for large power & customized gearboxes.

4. High quality gearboxes and proven solutions provider.

5. Strict quality control process, stable quality.

6. Less than 2% of the quality complaints.

7. Modular design, short delivery time.

8. Quick response & professional services.

AOKMAN was founded in 1982, which has more than 36 years in R & D and manufacturing of gearboxes, gears, shaft, motor and spare parts.

We can offer the proper solution for uncountable applications. Our products are widely used in the ranges of metallurgical, steel, mining, pulp and paper, sugar and alcohol market and various other types of machines with a strong presence in the international market.

AOKMAN has become a reliable supplier, able to supply high quality gearboxes.With 36 years experience, we assure you the utmost reliability and security for both product and services.

Other Product Businesses:

Our company mainly supplies various products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc.

We are committed to providing high-quality products, preferential prices, and considerate services. Customers are welcome to customize drawings and samples.

Frequently Asked Questions (FAQs):

1. What makes Aokman Precision Planetary Gearboxes stand out in the market?

2. Can Aokman Precision Planetary Gearboxes be used for servo applications?

3. What are the different types of backlash available for Aokman Precision Planetary Gearboxes?

4. How long has AOKMAN been in the R&D and manufacturing of gearboxes?

5. What industries can benefit from AOKMAN’s gearboxes and gear products?

All the content of this page is from the Internet and is only meant to serve as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you require original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Servo Gearbox

1. High Precision: Servo gearboxes are known for their precise positioning capabilities, ensuring accurate movement control.

2. High Efficiency: These gearboxes exhibit high efficiency, resulting in reduced energy consumption and improved overall performance.

3. Low Noise: Servo gearboxes are designed to operate with minimal noise, ensuring a quiet working environment.

4. Compact Design: The compact nature of servo gearboxes allows for easy integration into various applications, even with limited space.

5. High Torque Capacity: Servo gearboxes can handle high torque loads, making them suitable for demanding applications.

6. Smooth Operation: These gearboxes offer smooth and stable operation, eliminating vibrations and ensuring precise motion control.

7. Wide Speed Range: Servo gearboxes are capable of operating at various speeds, providing flexibility for different applications.

Types and Characteristics of Servo Gearbox

There are different types of servo gearboxes available to cater to specific application requirements. Some common types include planetary, helical, and worm gearboxes.

Planetary Gearbox: This type of servo gearbox offers high torque capacity, compact size, and high efficiency. It is commonly used in robotics and automation industries.

Helical Gearbox: Helical servo gearboxes provide smooth and quiet operation, making them suitable for applications where noise reduction is crucial. They are often used in medical equipment and precision machinery.

Worm Gearbox: Worm gearboxes are known for their high gear ratios and self-locking capabilities. They find applications in various industries, including renewable energy and automotive.

Advantages of Servo Gearbox Made of Different Materials

Servo gearboxes can be made of various materials, each offering specific advantages for different applications.

Steel Gearboxes: Steel gearboxes provide excellent strength and durability, making them suitable for heavy-duty applications that require high load capacity.

Aluminum Gearboxes: Aluminum gearboxes are lightweight and have good heat dissipation properties, making them ideal for applications where weight reduction and thermal management are important.

Composite Gearboxes: Composite gearboxes combine the advantages of different materials, such as strength, lightweight, and corrosion resistance, making them suitable for various industries, including aerospace and automotive.

Application of Servo Gearbox in Various Fields

Servo gearboxes play a vital role in different industries, showcasing their value and importance.

Automotive: Servo gearboxes are widely used in automotive applications, such as power steering systems and transmission systems, ensuring precise control and efficient power transfer.

Robotics: Servo gearboxes are essential for robotic systems, providing accurate movement control and enabling smooth operation for various robotic applications.

Medical Equipment: Servo gearboxes are utilized in medical equipment, such as surgical robots and imaging devices, where precise motion control and reliability are critical.

Renewable Energy: Servo gearboxes are employed in wind turbines and solar tracking systems, ensuring efficient power generation by accurately adjusting the rotor and solar panel positions.

Aerospace: Servo gearboxes are crucial for aerospace applications, including aircraft flight control systems and landing gear mechanisms, enabling precise control and safe operation.

Future Development Trends and Opportunities

The future of servo gearboxes looks promising, with several development trends on the horizon.

1. Miniaturization: There is a growing demand for smaller and more compact servo gearboxes to meet the requirements of space-constrained applications.

2. Integration with IoT: The integration of servo gearboxes with Internet of Things (IoT) technology allows for remote monitoring, predictive maintenance, and improved overall system performance.

3. Enhanced Efficiency: Continuous advancements in materials and design techniques aim to improve the efficiency of servo gearboxes, resulting in reduced energy consumption and increased cost-effectiveness.

4. Customization: The ability to customize servo gearboxes according to specific application needs provides opportunities for tailored solutions and improved performance.

5. Automation and Industry 4.0: Servo gearboxes will continue to play a crucial role in automation and the implementation of Industry 4.0, ensuring precise motion control and enabling smart manufacturing processes.

Choosing a Suitable Servo Gearbox

When selecting a servo gearbox, various factors should be considered to ensure the best fit for the application.

1. Load Requirements: Analyze the torque and speed requirements of the application to select a gearbox capable of handling the specific load.

2. Ratio Selection: Determine the desired gear ratio based on the desired output speed and torque, considering the application’s requirements.

3. Type of Gearbox: Select the appropriate type of servo gearbox, such as planetary, helical, or worm, based on the application’s needs and constraints.

4. Environmental Factors: Consider environmental conditions, such as temperature, humidity, and dust, to choose a gearbox that can withstand and operate reliably in such conditions.

5. Maintenance and Durability: Assess the maintenance requirements and expected lifespan of the gearbox, ensuring it aligns with the application’s needs and operational demands.

In conclusion, servo gearboxes offer high precision, efficiency, and low noise operation. They come in different types, each with unique characteristics and advantages. The application of servo gearboxes spans various industries, demonstrating their value and importance. The future holds promising opportunities for servo gearbox development, driven by trends such as miniaturization and integration with IoT. When selecting a servo gearbox, factors like load requirements, ratio selection, gearbox type, and environmental factors should be carefully considered. By choosing the right servo gearbox, optimal performance and reliability can be achieved in various applications.

Author: Dream

China high quality ZD Low Backlash High Torque Helical Precision Planetary Gearbox For Servo Motor Steeping air compressor parts

China High Quality ZD Low Backlash High Torque Helical Precision Planetary Gearbox For Servo Motor Stepping Air Compressor Parts

Product Description

The ZD Low Backlash High Torque Helical Precision Planetary Gearbox is a versatile reducer with exceptional performance. It features a compact structure, delivering large output torque with high speed ratios and efficiency. This gearbox is designed with safety and reliability in mind, ensuring optimal performance for various applications.

Our professional sales representatives and technical team are dedicated to selecting the ideal model and transmission solutions based on your specific parameters. If you require additional product parameters, catalogues, CAD or 3D drawings, please don’t hesitate to reach out to us.

We understand that each customer has unique requirements. Therefore, we offer the option to modify our standard products or even customize them to meet your specific needs.

Range Of Planetary Gearbox

At our company, we specialize in supplying a wide range of high-quality industrial products. Our extensive product range includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in offering superior products at competitive prices, accompanied by excellent customer service.

Customers are welcome to customize drawings and samples, as we are committed to meeting your individual requirements.

Frequently Asked Questions (FAQs)

1. How can I determine the right model and transmission solution for my application?

Our professional sales representatives and technical team will assist you in choosing the optimal model and transmission solution based on your specific parameters. We take into consideration factors such as torque requirements, speed ratios, and performance expectations to ensure the best fit for your application.

2. Can I request additional product information or drawings?

Absolutely! If you need more detailed product parameters, catalogues, CAD or 3D drawings, please don’t hesitate to contact us. Our team will be happy to provide you with the requested information.

3. Can your planetary gearboxes be modified or customized?

Yes, we offer the option to modify our standard products or even customize them to meet your specific needs. We understand that every application is unique, and we are dedicated to providing tailored solutions for our customers.

4. What other products does your company offer?

Our company specializes in supplying various industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in offering a comprehensive range of products to meet our customers’ diverse needs.

5. Do you offer customization services for drawings and samples?

Yes, we welcome customers to customize drawings and samples according to their specific requirements. Our dedicated team is here to ensure that your unique needs are met, providing you with tailored solutions and exceptional service.

All the content of this page is from the Internet and is only meant to serve as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you require original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Servo Gearbox

1. High Precision: Servo gearboxes are known for their precise positioning capabilities, ensuring accurate movement control.

2. High Efficiency: These gearboxes exhibit high efficiency, resulting in reduced energy consumption and improved overall performance.

3. Low Noise: Servo gearboxes are designed to operate with minimal noise, ensuring a quiet working environment.

4. Compact Design: The compact nature of servo gearboxes allows for easy integration into various applications, even with limited space.

5. High Torque Capacity: Servo gearboxes can handle high torque loads, making them suitable for demanding applications.

6. Smooth Operation: These gearboxes offer smooth and stable operation, eliminating vibrations and ensuring precise motion control.

7. Wide Speed Range: Servo gearboxes are capable of operating at various speeds, providing flexibility for different applications.

Types and Characteristics of Servo Gearbox

There are different types of servo gearboxes available to cater to specific application requirements. Some common types include planetary, helical, and worm gearboxes.

Planetary Gearbox: This type of servo gearbox offers high torque capacity, compact size, and high efficiency. It is commonly used in robotics and automation industries.

Helical Gearbox: Helical servo gearboxes provide smooth and quiet operation, making them suitable for applications where noise reduction is crucial. They are often used in medical equipment and precision machinery.

Worm Gearbox: Worm gearboxes are known for their high gear ratios and self-locking capabilities. They find applications in various industries, including renewable energy and automotive.

Advantages of Servo Gearbox Made of Different Materials

Servo gearboxes can be made of various materials, each offering specific advantages for different applications.

Steel Gearboxes: Steel gearboxes provide excellent strength and durability, making them suitable for heavy-duty applications that require high load capacity.

Aluminum Gearboxes: Aluminum gearboxes are lightweight and have good heat dissipation properties, making them ideal for applications where weight reduction and thermal management are important.

Composite Gearboxes: Composite gearboxes combine the advantages of different materials, such as strength, lightweight, and corrosion resistance, making them suitable for various industries, including aerospace and automotive.

Application of Servo Gearbox in Various Fields

Servo gearboxes play a vital role in different industries, showcasing their value and importance.

Automotive: Servo gearboxes are widely used in automotive applications, such as power steering systems and transmission systems, ensuring precise control and efficient power transfer.

Robotics: Servo gearboxes are essential for robotic systems, providing accurate movement control and enabling smooth operation for various robotic applications.

Medical Equipment: Servo gearboxes are utilized in medical equipment, such as surgical robots and imaging devices, where precise motion control and reliability are critical.

Renewable Energy: Servo gearboxes are employed in wind turbines and solar tracking systems, ensuring efficient power generation by accurately adjusting the rotor and solar panel positions.

Aerospace: Servo gearboxes are crucial for aerospace applications, including aircraft flight control systems and landing gear mechanisms, enabling precise control and safe operation.

Future Development Trends and Opportunities

The future of servo gearboxes looks promising, with several development trends on the horizon.

1. Miniaturization: There is a growing demand for smaller and more compact servo gearboxes to meet the requirements of space-constrained applications.

2. Integration with IoT: The integration of servo gearboxes with Internet of Things (IoT) technology allows for remote monitoring, predictive maintenance, and improved overall system performance.

3. Enhanced Efficiency: Continuous advancements in materials and design techniques aim to improve the efficiency of servo gearboxes, resulting in reduced energy consumption and increased cost-effectiveness.

4. Customization: The ability to customize servo gearboxes according to specific application needs provides opportunities for tailored solutions and improved performance.

5. Automation and Industry 4.0: Servo gearboxes will continue to play a crucial role in automation and the implementation of Industry 4.0, ensuring precise motion control and enabling smart manufacturing processes.

Choosing a Suitable Servo Gearbox

When selecting a servo gearbox, various factors should be considered to ensure the best fit for the application.

1. Load Requirements: Analyze the torque and speed requirements of the application to select a gearbox capable of handling the specific load.

2. Ratio Selection: Determine the desired gear ratio based on the desired output speed and torque, considering the application’s requirements.

3. Type of Gearbox: Select the appropriate type of servo gearbox, such as planetary, helical, or worm, based on the application’s needs and constraints.

4. Environmental Factors: Consider environmental conditions, such as temperature, humidity, and dust, to choose a gearbox that can withstand and operate reliably in such conditions.

5. Maintenance and Durability: Assess the maintenance requirements and expected lifespan of the gearbox, ensuring it aligns with the application’s needs and operational demands.

In conclusion, servo gearboxes offer high precision, efficiency, and low noise operation. They come in different types, each with unique characteristics and advantages. The application of servo gearboxes spans various industries, demonstrating their value and importance. The future holds promising opportunities for servo gearbox development, driven by trends such as miniaturization and integration with IoT. When selecting a servo gearbox, factors like load requirements, ratio selection, gearbox type, and environmental factors should be carefully considered. By choosing the right servo gearbox, optimal performance and reliability can be achieved in various applications.

Author: Dream

China best ZD High Precision Low Backlash Spur or Helical Gear Planetary Speed Gear Reducer Gearbox For Servo Motor Steeping Motor with high quality

ZD High Precision Low Backlash Spur or Helical Gear Planetary Speed Gear Reducer Gearbox For Servo Motor Steeping Motor

Our ZD High Precision Low Backlash Spur or Helical Gear Planetary Speed Gear Reducer Gearbox is the perfect solution for your servo motor and stepping motor needs. With its wide versatility, the planetary gearbox is an excellent reducer that can meet the needs of a variety of applications. The inner gear is made of low carbon alloy steel that undergoes the carburizing quenching and grinding or nitriding process, making it durable and reliable.

Model Selection

Our ZD High Precision Low Backlash Spur or Helical Gear Planetary Speed Gear Reducer Gearbox comes in a range of models that can suit your specific application needs. Whether you need a spur gear or helical gear, we have the right precision reducer for you.

Range of Planetary Gearbox

Our planetary gearbox has a small structure size, large output torque, high speed ratio, high efficiency, and safe and reliable performance, making it the perfect solution for a variety of industrial uses.

Customized Product Service

At our company, we pride ourselves on providing quality, customized products for our customers. We offer a range of products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We welcome customers to customize their drawings and samples to ensure their specific needs are met.

FAQs

Q: What is the inner gear made of?

A: The inner gear of our ZD High Precision Low Backlash Spur or Helical Gear Planetary Speed Gear Reducer Gearbox is made of low carbon alloy steel that undergoes the carburizing quenching and grinding or nitriding process, making it durable and reliable.

Q: What types of applications is the planetary gearbox suitable for?

A: The planetary gearbox is versatile and can be used in a variety of industrial applications due to its small structure size, large output torque, high speed ratio, high efficiency, and safe and reliable performance.

Q: What other products do you offer?

A: Our company offers an extensive range of products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more.

Q: Can I customize my order?

A: Yes, we welcome customers to customize their orders by providing drawings and samples to ensure their specific needs are met.

Q: What makes your company stand out?

A: Our company prides itself on providing high-quality products, preferential prices, and considerate services. We strive to meet our customers’ needs by offering customized products and exceptional customer service.

All the content of this page is from the Internet and is only meant to serve as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you require original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Servo Gearbox

1. High Precision: Servo gearboxes are known for their precise positioning capabilities, ensuring accurate movement control.

2. High Efficiency: These gearboxes exhibit high efficiency, resulting in reduced energy consumption and improved overall performance.

3. Low Noise: Servo gearboxes are designed to operate with minimal noise, ensuring a quiet working environment.

4. Compact Design: The compact nature of servo gearboxes allows for easy integration into various applications, even with limited space.

5. High Torque Capacity: Servo gearboxes can handle high torque loads, making them suitable for demanding applications.

6. Smooth Operation: These gearboxes offer smooth and stable operation, eliminating vibrations and ensuring precise motion control.

7. Wide Speed Range: Servo gearboxes are capable of operating at various speeds, providing flexibility for different applications.

Types and Characteristics of Servo Gearbox

There are different types of servo gearboxes available to cater to specific application requirements. Some common types include planetary, helical, and worm gearboxes.

Planetary Gearbox: This type of servo gearbox offers high torque capacity, compact size, and high efficiency. It is commonly used in robotics and automation industries.

Helical Gearbox: Helical servo gearboxes provide smooth and quiet operation, making them suitable for applications where noise reduction is crucial. They are often used in medical equipment and precision machinery.

Worm Gearbox: Worm gearboxes are known for their high gear ratios and self-locking capabilities. They find applications in various industries, including renewable energy and automotive.

Advantages of Servo Gearbox Made of Different Materials

Servo gearboxes can be made of various materials, each offering specific advantages for different applications.

Steel Gearboxes: Steel gearboxes provide excellent strength and durability, making them suitable for heavy-duty applications that require high load capacity.

Aluminum Gearboxes: Aluminum gearboxes are lightweight and have good heat dissipation properties, making them ideal for applications where weight reduction and thermal management are important.

Composite Gearboxes: Composite gearboxes combine the advantages of different materials, such as strength, lightweight, and corrosion resistance, making them suitable for various industries, including aerospace and automotive.

Application of Servo Gearbox in Various Fields

Servo gearboxes play a vital role in different industries, showcasing their value and importance.

Automotive: Servo gearboxes are widely used in automotive applications, such as power steering systems and transmission systems, ensuring precise control and efficient power transfer.

Robotics: Servo gearboxes are essential for robotic systems, providing accurate movement control and enabling smooth operation for various robotic applications.

Medical Equipment: Servo gearboxes are utilized in medical equipment, such as surgical robots and imaging devices, where precise motion control and reliability are critical.

Renewable Energy: Servo gearboxes are employed in wind turbines and solar tracking systems, ensuring efficient power generation by accurately adjusting the rotor and solar panel positions.

Aerospace: Servo gearboxes are crucial for aerospace applications, including aircraft flight control systems and landing gear mechanisms, enabling precise control and safe operation.

Future Development Trends and Opportunities

The future of servo gearboxes looks promising, with several development trends on the horizon.

1. Miniaturization: There is a growing demand for smaller and more compact servo gearboxes to meet the requirements of space-constrained applications.

2. Integration with IoT: The integration of servo gearboxes with Internet of Things (IoT) technology allows for remote monitoring, predictive maintenance, and improved overall system performance.

3. Enhanced Efficiency: Continuous advancements in materials and design techniques aim to improve the efficiency of servo gearboxes, resulting in reduced energy consumption and increased cost-effectiveness.

4. Customization: The ability to customize servo gearboxes according to specific application needs provides opportunities for tailored solutions and improved performance.

5. Automation and Industry 4.0: Servo gearboxes will continue to play a crucial role in automation and the implementation of Industry 4.0, ensuring precise motion control and enabling smart manufacturing processes.

Choosing a Suitable Servo Gearbox

When selecting a servo gearbox, various factors should be considered to ensure the best fit for the application.

1. Load Requirements: Analyze the torque and speed requirements of the application to select a gearbox capable of handling the specific load.

2. Ratio Selection: Determine the desired gear ratio based on the desired output speed and torque, considering the application’s requirements.

3. Type of Gearbox: Select the appropriate type of servo gearbox, such as planetary, helical, or worm, based on the application’s needs and constraints.

4. Environmental Factors: Consider environmental conditions, such as temperature, humidity, and dust, to choose a gearbox that can withstand and operate reliably in such conditions.

5. Maintenance and Durability: Assess the maintenance requirements and expected lifespan of the gearbox, ensuring it aligns with the application’s needs and operational demands.

In conclusion, servo gearboxes offer high precision, efficiency, and low noise operation. They come in different types, each with unique characteristics and advantages. The application of servo gearboxes spans various industries, demonstrating their value and importance. The future holds promising opportunities for servo gearbox development, driven by trends such as miniaturization and integration with IoT. When selecting a servo gearbox, factors like load requirements, ratio selection, gearbox type, and environmental factors should be carefully considered. By choosing the right servo gearbox, optimal performance and reliability can be achieved in various applications.

Author: Dream

China best Low Backlash Plf Ple Series Plf40 Plf60 Plf90 Plf120 Planetary Gearbox for Servo Motor Wple120/Ple60/Pn80/Ple90/PS80/PF80 with high quality

China Best Low Backlash PLF PLE Series Planetary Gearbox for Servo Motor

Why should servo motors be equipped with planetary reducers? The function of a servo motor is to carry out precise positioning. The reducer adjusts the motor’s output speed and torque to meet the requirements. Since the speed output of the motor is usually constant, but the required speed varies greatly, a reducer is necessary to adjust to the required speed range. Simply increasing the power of the servo motor to meet the required torque when the load is very large would result in unnecessary cost waste. Therefore, selecting a suitable servo reducer within the required speed range is a reasonable approach. The servo reducer itself slows down the speed and increases the output torque. In simple terms, the servo motor and reducer are like twins.

Product Description

The PLF PLE Series Planetary Gearbox is designed to enhance the performance of servo motors. It provides precise speed adjustment and increased output torque, making it ideal for applications that require low speed and high torque. With a gearing arrangement of planetary type, it ensures smooth and efficient power transmission. The gearbox has a wide range of output torque options, ranging from 10Nm to 2100Nm, making it suitable for various industrial applications. It can be mounted in any direction, offering flexibility in installation. The compact size, ranging from 42mm to 220mm, allows for easy integration into different systems. The gearbox comes in an attractive silver-blue color, adding a touch of style to your machinery.

Industry-specific Attributes

- Gearing Arrangement: Planetary

- Output Torque: 10-2100Nm

- Input Speed: Based on motor

- Output Speed: Based on ratio

Other Attributes

- Applicable Industries: Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Food Shop, Printing Shops, Construction works, Energy & Mining, Food & Beverage Shops

- Weight (KG): 9

- Place of Origin: Shanghai, China

- Brand Name: CHINAMFG

- Application: Textile, Food Processing Machine, CNC, AGV, Robotic Industry

- Mounting Position: Any direction

- Gearbox Size: 42 ~ 220mm

- Color: Silver blue

- Ratio: 3 ~ 512

- Warranty: One year after the day of ex-factory

- Packing: Wooden box or carton

- Input Form: IEC Flange

- Certificate: CE & ISO

- Structures: Bearing + Gear + Box

Packaging and Delivery

- Port: Zhejiang

Lead Time

| Quantity (sets) | 1 – 10 | > 10 |

| Lead time (days) | 12 | To be negotiated |

View More

Our company mainly supplies various products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc. We take pride in offering high-quality products, competitive prices, and excellent customer service. We welcome customization requests based on drawings and samples.

Frequently Asked Questions (FAQs)

1. What is the purpose of equipping servo motors with planetary reducers?

Servo motors require precise positioning, while the reducers adjust the motor’s output speed and torque to meet the requirements. Planetary reducers, in particular, provide excellent speed adjustment and increased torque, making them a perfect match for servo motors.

2. How does the PLF PLE Series Planetary Gearbox enhance servo motor performance?

The PLF PLE Series Planetary Gearbox improves servo motor performance by offering precise speed adjustment and increased torque output. This ensures that the motor meets the varying speed requirements of different applications, providing optimal performance and efficiency.

3. Can the PLF PLE Series Planetary Gearbox be mounted in any direction?

Yes, the PLF PLE Series Planetary Gearbox is designed to be mounted in any direction, providing flexibility in installation. This allows for easy integration into different systems, making it suitable for a wide range of industrial applications.

4. What industries can benefit from using the PLF PLE Series Planetary Gearbox?

The PLF PLE Series Planetary Gearbox is suitable for various industries, including garment shops, building material shops, manufacturing plants, machinery repair shops, food and beverage factories, farms, retail stores, printing shops, construction works, energy and mining sectors, and food and beverage shops.

5. What are the warranty terms for the PLF PLE Series Planetary Gearbox?

The PLF PLE Series Planetary Gearbox comes with a one-year warranty from the day of ex-factory. This warranty ensures that you receive a high-quality product and guarantees its performance and reliability.

All the content of this page is from the Internet and is only meant to serve as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in this content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you require original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Servo Gearbox

1. High Precision: Servo gearboxes are known for their precise positioning capabilities, ensuring accurate movement control.

2. High Efficiency: These gearboxes exhibit high efficiency, resulting in reduced energy consumption and improved overall performance.

3. Low Noise: Servo gearboxes are designed to operate with minimal noise, ensuring a quiet working environment.

4. Compact Design: The compact nature of servo gearboxes allows for easy integration into various applications, even with limited space.

5. High Torque Capacity: Servo gearboxes can handle high torque loads, making them suitable for demanding applications.

6. Smooth Operation: These gearboxes offer smooth and stable operation, eliminating vibrations and ensuring precise motion control.

7. Wide Speed Range: Servo gearboxes are capable of operating at various speeds, providing flexibility for different applications.

Types and Characteristics of Servo Gearbox

There are different types of servo gearboxes available to cater to specific application requirements. Some common types include planetary, helical, and worm gearboxes.